Some time ago I ran across an unusual adaptor, made by Peter Manton to suit the Nikki carburettor. The adaptor was part of John Brown’s collection (see Page 7 of this thread: http://www.fbekholden.com/forum/viewtop ... on#p215754). As luck would have it, I purchased an identical adaptor as part of a mixed box of carby odds and ends. The adaptor got me curious, so I have done a little digging into it. The info below is far from complete, but gives an idea of where this adaptor fits into the grey motor world.

Peter Manton DGN Nikki Adaptor

The Peter Manton DGN Nikki adaptor is a cast item that allows the four-bolt rectangular Nikki carburetor flange (80mm x 44mm bolt centers) to be bolted to a two-bolt SAE-1 flange (2 3/8” bolt centers). This allows the adaptor to be used on the Holden grey motor. The adaptor I have has been slotted to also suit the SAE-2 flange (2 11/16” bolt centres) commonly seen on red motors. Note that the Nikki carburetor is similar to, but not the same flange pattern as the larger WW Stromberg (~89mm x 48mm bolt centres) or 350 Holley (~131mm x 88mm bolt centres).

The image below shows the adaptor and a Nikki carburettor on the Holden grey motor inlet manifold. I have oriented the float bowl to the rear of the vehicle – it could equally (and probably more sensibly) be oriented to the front.

The adaptor throttle bore (outlet diameter) is 1 5/16”, identical to the grey motor inlet manifold. This makes for a moderately smooth flow transition from the Nikki to a grey motor manifold. The assembled Nikki and adaptor stands some 7.28” tall (slightly shorter than the grey motor BXOV-1 Stromberg at 7.45”) and is unlikely to cause bonnet clearance issues. The Nikki does however have a larger air horn neck (3.14” diameter compared to the Stromberg at 2.27”), requiring a different air cleaner than the factory Stromberg. The Nikki is set up for a cable accelerator, unlike the factory early Holden linkage rod setup. The float orientation of the Nikki (east/west) remains the same as the Stromberg, minimising fuel surge issues.

History

Gerald Peter Manton was born in Melbourne in 1922, and began racing at age seventeen in his mother’s Austin 16. Peter worked at the Government Aircraft Factory at Fisherman’s Bend in Product Engineering, leaving to work for Jack Ould (and eventually become a partner) at Monaro Motors around 1951. The business was then focused on selling MGs and manufacturing various improvement parts. They were also agents for Wade superchargers, and became the sole Victorian distributors for SU carburetors. Peter progressed to design and research, developing many twin carburetor manifolds and other performance improvement gear. In the early 1960’s Peter swapped his Marshall-blown Morris Major for Minis, for which he remains renowned. Peter would go on to run Peter Manton Motors, a supplier of parts to Mini enthusiasts.

Given Peter’s strong interaction with BMC, it is likely that the Nikki adaptor as intended to for use on BMC vehicles rather than the Holden grey motor. It is likely that the DGN cast into the adaptor stands for “Design”.

Nikki was originally established in 1932 as the Nippon Carburetor Company, and was Japan’s first carburetor factory. It produced both carburetors and fuel pumps for the automotive, agricultural and aircraft industries. The two-stage 2-barrel carburetor was developed in 1956, and the four-barrel in 1964. EFI followed in 1984. The company changed name to Nikki Company in 2001. Along the way, a number of subsidiaries were established - the Nikki Techno Company (1989), the Shenyang Rixin Carburetor Corporation and Nikki America (1998), the Changzhou Guangri Precision Machinery Company (2000), Nikki Soltech Company (2004), Nikki Korea Company and Nikki America Fuel Systems (2005), Nikki India Fuel Systems (2011) and Nikki Thailand Company (2013). Nikki fuel systems have been used by a wide variety of manufacturers, including Nissan, Toyota, Mazda, Isuzu, Mitsubishi, Daihatsu and GMH. For GMH, the Nikki carburettor is most synonymous with the Holden Gemini motors - TX (1975–1977), TC (1977–1978), TD (1978–1979), TE (1979–1982), TF (1982–1983), TG (1983–1985) and RB (1985-1987).

Carburettor Identification

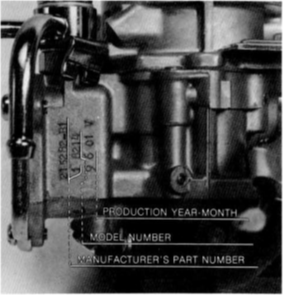

Nikki carburettors may be identified by markings inked onto the side of the float bowl, as shown in the image below.

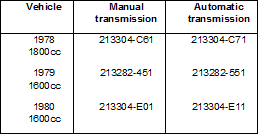

My Gemini factory workshop manuals are limited to the 1979 and 1980 years, and have only the following carburettor model numbers listed:

Inked onto the side of my carburettor (a TE Gemini 1800cc Nikki) are:

304-91

01-b,

86-43 (maybe this is 82-43, as TE’s were not made in 86).

(stop laughing about my Gemini stuff... think of it as a miss-spent youth

The Niki Carburetor on a Grey Motor

There is no doubt that installing a larger carburetor onto an engine increases the ability of the engine to flow more air. However, the carburetor is not just a restriction device – it needs to control fuel for idle, acceleration and cruise. The larger venturi of a “big carb” has less pressure drop, which in turn means that the “I need more or less fuel” signal being given to idle, acceleration and cruise circuits is also less sharp. Choose too large a carburetor, and the results can be poor – the throttle opens, lots of air gets in, little signal for fuel, and the engine bogs down.

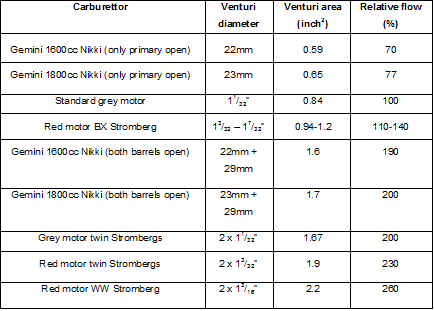

Very little information is available on the flow capability (CFM) of the Nikki carburetor. An alternate way to compare carburetor capacity is to examine venturi size. Flow through a perfect venturi is proportional to the cross sectional area. A carburettor is not a perfect venturi (for example it has throttle plates and booster venturis in the way of the flow). However, the cross sectional area gives us a decent way to (roughly) compare flow capabilities of two carburettors. For the Gemini Nikkis, the 1600cc model had a 22mm diameter primary and a 29mm secondary. The 1800cc model had a 23mm primary and a 29mm secondary.

The beauty of the Nikki carburettor is that it has a vacuum secondary. This is unlike both the WW Stromberg and 350 Holley, both of which have mechanical secondaries (and both of which have secondaries that open at the same time as the primaries). For the Nikki under idle and low load conditions, only the primary barrel opens. From the table above, we can see that the Nikki primary barrel is only about ¾ the size of the grey motor Stromberg. This is not an issue, it just means that under low load the Nikki would open up a bit more than the Strommie would have. As load increases, the Nikki secondary barrel opens. From the table above we can see that a wide open Gemini Nikki has about the same flow capability as twin Grey motor Strombergs.

So which is the better choice – a Nikki or twin Strombergs? The Nikki will perform better down low, with the small primary venturi eliminating some of the boggy performance that can come with twin Strombergs. The secondaries open up smoothly, giving the same (or better) transition to full-throttle. Top end should be pretty similar to the twin Strombergs. This is similar to the way that a 4-barrell 390 Holley works so much better than a 350 Holley on a on a red motor (see http://www.fbekholden.com/forum/viewtop ... ley+loving for more of that). The Nikki however bolts on through the standard grey motor manifold. This manifold does not distribute fuel as well as the twin Stromberg manifold does (the single Stromberg tends to overfeed the centre cylinders, and starve cylinders 1 and 6).

All up, the Nikki is pretty comparable to the twin Stromberg setup. For someone wanting something a little different, it is not a bad choice.

Cheers,

Harv