Dragway wheels to an EK

Dragway wheels to an EK

Hi all,

I thought it better if I started my own thread on this subject - I have not composed a "novel" for some time and have spent the past four weeks in research -

be WARNED!

this will be long, hard and there will be no surrender.....

those wishing not to trawl through this STOP HERE - do NOT proceed........

I am going to have to break it up into quite a few bits and this will be the first of about three or four.

Chapter 1 ........

Dragway wheels.

They have been around for many years - started by Ian Splatt of drag racing fame... later to be followed by this daughter, Rachelle......

They originated at Kinglake West - factory still operates from there - 21 km's from the Melba Highway turnoff.

The factory is a bit like a Tardis - I was fortunate to get a look around inside - from the outside it appears a small factory shopfront with a roller door adjacent to the retail area.... do not be fooled, this is a major business - there are two separate production areas inside - with machines I could only dream of - many of them computer controlled..... I could type and type about this but not here.....

Dragway is an Austalian company.

My dealings have been entirely with the prop of this factory - Ray Dunn.

Now, the facts...

I am ONLY going to address what I have researched... that being the current availability of both the "revised" and "new" style 5 spoke wheel.

Have to upload some pix...... to be continued...

frats,

Rosco

I thought it better if I started my own thread on this subject - I have not composed a "novel" for some time and have spent the past four weeks in research -

be WARNED!

this will be long, hard and there will be no surrender.....

those wishing not to trawl through this STOP HERE - do NOT proceed........

I am going to have to break it up into quite a few bits and this will be the first of about three or four.

Chapter 1 ........

Dragway wheels.

They have been around for many years - started by Ian Splatt of drag racing fame... later to be followed by this daughter, Rachelle......

They originated at Kinglake West - factory still operates from there - 21 km's from the Melba Highway turnoff.

The factory is a bit like a Tardis - I was fortunate to get a look around inside - from the outside it appears a small factory shopfront with a roller door adjacent to the retail area.... do not be fooled, this is a major business - there are two separate production areas inside - with machines I could only dream of - many of them computer controlled..... I could type and type about this but not here.....

Dragway is an Austalian company.

My dealings have been entirely with the prop of this factory - Ray Dunn.

Now, the facts...

I am ONLY going to address what I have researched... that being the current availability of both the "revised" and "new" style 5 spoke wheel.

Have to upload some pix...... to be continued...

frats,

Rosco

Last edited by rosco on Sat Oct 04, 2008 10:47 am, edited 1 time in total.

chapter 2

Back again,

just had to put a couple of pix into photbucket.....

this is probably how this is going to run, type a bit - add some pix and type some more - in chapters.

I'll take a break ( 1 minute to 1 week) as I need it.

Chapter 2

Classic 5 spoke wheels.

The original wheel is no longer available - it hasn't been in production for some time - but as it was shown to me, just about anyone here will be very hard pressed to pick the difference in what has replaced it....

The replacement wheel is called the "revised"..... I'm going to divulge just how you will spot the difference - the revised has a very slightly narrower "coned" spoke - but you'll have to get up early to pick it..... it is very, very minimal - the Dragway people can pick them instantly ...... it took me a few seconds to spot it.....

The "revised" wheel looks like this....

What I want you to look closely at is the spokes and their placement in the wheel - particularly where they are fixed (yes - these are two piece wheels - the centre is alloy - the rim is chromed steel).

In the revised wheel, you will notice that the coned spokes angle out from the centre hub - this is a distance of 5/8" (important in the coming chapters).

This wheel is currently available and retails for $429 each including nuts and domes - for 13 x 6 or 7 and 14 x 6...... yes, very expensive - but you'll learn a bit more about this as my tale goes on.....

These are the wheels I would dearly have loved to have put on my old bus...... but can't - not even with knocking out the inner guards and lip of the rear fenders........

Before we get into a cat-fight....... I can only tell you what I have found with my car - the wheels currently available and the altered running gear I am using......

I make absolutely no comment on who, what or how others have managed to achieve running these wheels ........ OK?

I have been working with someone else on this forum for a little while - and we are currently in two minds as to the direction each will take.....

Back to the wheels....

All steel rims for classic wheels have a 2" outer rim - from where the spoke is mounted to the outer edge (where the tyre and weights are fitted) - some have probably jumped ahead and know exactly why am taking the time to explain the importance of these spokes......

There is a relatively recent addition to the 5 spoke wheel..... and is known as the "new" (funny that) edition classic 5 spoke and looks like this..

from the side on view, you will notice that the spoke is narrower...

The next pic depicts the position of this narrower spoke and also clearly shows that they run vertically - not set outwards (angled towards the rim)

This is the BIG difference in fitting these to our models......

Many modern vehicles have been designed to have wheels fitted where they are mounted onto hubs almost at the outer end of the suspension - our poor old things were not..... if you look at your steel wheel - you will note there is a recess where the wheel actually "steps back" behind the hub...

It is probably for this reason Dragway have created this wheel ... I am only assuming here - but you willl agree there are fewer and fewer of our older type vehicles in the market place.....

By creating this wheel, it affords us an extra 5/8" clearance from the outer rim to the closest part of the outboard body..... at the rear, it is the lip of the guard .... closely followed by the inner guard which tapers narrower as you move up into the arch......

Now - the acid........

After my first visit to Kinglake - I came away pretty confident I could still get the revised wheel to fit..... I was told that I would have to "roll" the lips of the rear guards but would still have problems.....

The measurements I was given were 4 1/8" for the "revised" and 3 1/2" for the "new"....

These figures are calculated by running a straight edge along vertically along the wheel mounting face of the brake drum or disc hub......

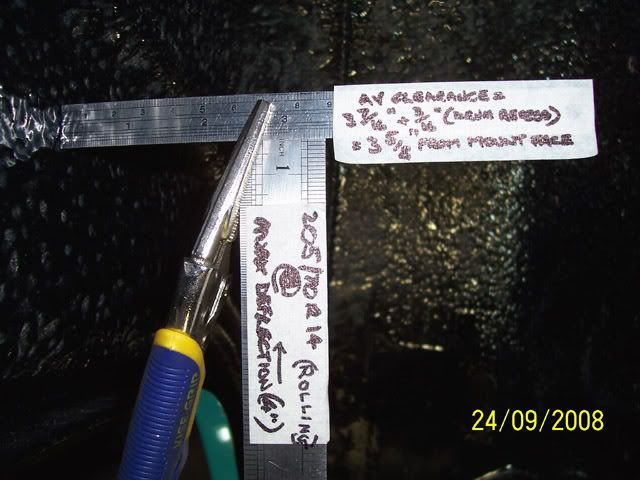

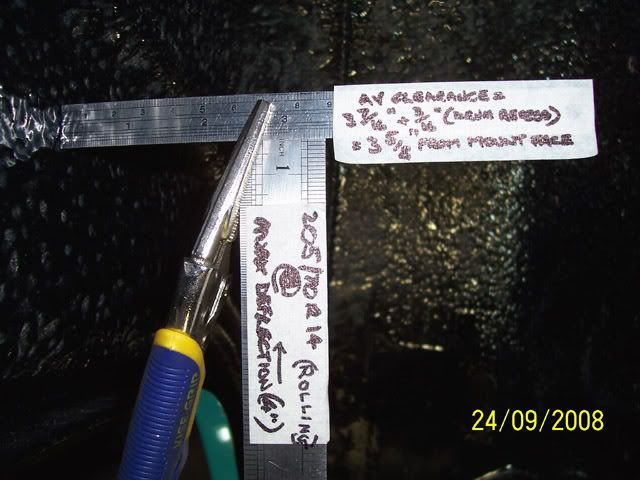

I fitted a 24" ruler to two studs of the rear wheel mount with the car sitting at ride height.

From that vertical straight edge, I ran a 6" ruler at right angles to the inner guard and rolled over lip......

pix - to save you another 1K words......

My desired 4 1/4" soon got "totalled"..... bearing in mind - this is for wheel touching and does NOT inlcude tyre...... read on......

What became obvious, was that I barely had 3 1/2" and this was the absolute "interference" fit for the "new" wheel - it does not afford any "bulge" extension for the tyre - nor spring lateral movement......

There are, however, a couple of considerations.......

The wheel is actually mounted 3/16" recessed into the brake drum - you MUST understand that this is for an HR rear brake drum - I cannot recall how the FB/EK drum is cast - I feel it is a flat face and your measurements will result in what the HR does allowing for this recess.....

This now gives us a (wheel mount face) clearance from the body of 3 11/16" ...... just 3/16" to spare - not including tyre ....

The HR disc brake hubs on the front do not present any issue - except the clearance of the wheel over the caliper - many people have in fact gone to LH/X Torana calipers - they have one piston which is mounted inboard and affords quite a bit more room for the mount face of the hub to pass over....... read on - we'll get to the front in a later chapter......

The rear.... revisited....

Over the next few days, I spent many hours on my back under the car - with rulers, straight edges, levels, jacks and stands - lifting this, stretching that and for the life of my lack of intelligence - I could not conceivable find any way that either of these wheels were going to fit.....

Posts on the forum in the meantime were offering some comforting hope...... I must be the biggest dummy out - it is well beyond my intelligence on how you can fit a wheel and tyre (absolute stretch and almost vertical walled) requiring 3 5/8" into a clearance of 3 11/16" decreasing as it goes upwards.........

The next week I made the trek back to Kinglake and took many pix and measurements with me - resulting in confirmation that these would not fit the rear unless the body is altered to accommodate them........

I drove the poor chap mad....... questions, questions, questions... I could see that he needed to get back into the factory - he was absolutely daubed in alloy dust and "buff"....... but I must state - very hospitable and open to all suggestions......

Understanding my passion for these wheels - he offered me an option which I do not believe would have arisen if not for my persistence ....

It seemed they were going to do a run of 14 x 6 rims for our stud pattern the following week..... his offer... if you are extremely carefull - come and pick one of these up and take it home to trial fit it..... I jumped.......

This is the end of today's chapter folk....... stay tuned - there's heaps to come......

frats,

Rosco

just had to put a couple of pix into photbucket.....

this is probably how this is going to run, type a bit - add some pix and type some more - in chapters.

I'll take a break ( 1 minute to 1 week) as I need it.

Chapter 2

Classic 5 spoke wheels.

The original wheel is no longer available - it hasn't been in production for some time - but as it was shown to me, just about anyone here will be very hard pressed to pick the difference in what has replaced it....

The replacement wheel is called the "revised"..... I'm going to divulge just how you will spot the difference - the revised has a very slightly narrower "coned" spoke - but you'll have to get up early to pick it..... it is very, very minimal - the Dragway people can pick them instantly ...... it took me a few seconds to spot it.....

The "revised" wheel looks like this....

What I want you to look closely at is the spokes and their placement in the wheel - particularly where they are fixed (yes - these are two piece wheels - the centre is alloy - the rim is chromed steel).

In the revised wheel, you will notice that the coned spokes angle out from the centre hub - this is a distance of 5/8" (important in the coming chapters).

This wheel is currently available and retails for $429 each including nuts and domes - for 13 x 6 or 7 and 14 x 6...... yes, very expensive - but you'll learn a bit more about this as my tale goes on.....

These are the wheels I would dearly have loved to have put on my old bus...... but can't - not even with knocking out the inner guards and lip of the rear fenders........

Before we get into a cat-fight....... I can only tell you what I have found with my car - the wheels currently available and the altered running gear I am using......

I make absolutely no comment on who, what or how others have managed to achieve running these wheels ........ OK?

I have been working with someone else on this forum for a little while - and we are currently in two minds as to the direction each will take.....

Back to the wheels....

All steel rims for classic wheels have a 2" outer rim - from where the spoke is mounted to the outer edge (where the tyre and weights are fitted) - some have probably jumped ahead and know exactly why am taking the time to explain the importance of these spokes......

There is a relatively recent addition to the 5 spoke wheel..... and is known as the "new" (funny that) edition classic 5 spoke and looks like this..

from the side on view, you will notice that the spoke is narrower...

The next pic depicts the position of this narrower spoke and also clearly shows that they run vertically - not set outwards (angled towards the rim)

This is the BIG difference in fitting these to our models......

Many modern vehicles have been designed to have wheels fitted where they are mounted onto hubs almost at the outer end of the suspension - our poor old things were not..... if you look at your steel wheel - you will note there is a recess where the wheel actually "steps back" behind the hub...

It is probably for this reason Dragway have created this wheel ... I am only assuming here - but you willl agree there are fewer and fewer of our older type vehicles in the market place.....

By creating this wheel, it affords us an extra 5/8" clearance from the outer rim to the closest part of the outboard body..... at the rear, it is the lip of the guard .... closely followed by the inner guard which tapers narrower as you move up into the arch......

Now - the acid........

After my first visit to Kinglake - I came away pretty confident I could still get the revised wheel to fit..... I was told that I would have to "roll" the lips of the rear guards but would still have problems.....

The measurements I was given were 4 1/8" for the "revised" and 3 1/2" for the "new"....

These figures are calculated by running a straight edge along vertically along the wheel mounting face of the brake drum or disc hub......

I fitted a 24" ruler to two studs of the rear wheel mount with the car sitting at ride height.

From that vertical straight edge, I ran a 6" ruler at right angles to the inner guard and rolled over lip......

pix - to save you another 1K words......

My desired 4 1/4" soon got "totalled"..... bearing in mind - this is for wheel touching and does NOT inlcude tyre...... read on......

What became obvious, was that I barely had 3 1/2" and this was the absolute "interference" fit for the "new" wheel - it does not afford any "bulge" extension for the tyre - nor spring lateral movement......

There are, however, a couple of considerations.......

The wheel is actually mounted 3/16" recessed into the brake drum - you MUST understand that this is for an HR rear brake drum - I cannot recall how the FB/EK drum is cast - I feel it is a flat face and your measurements will result in what the HR does allowing for this recess.....

This now gives us a (wheel mount face) clearance from the body of 3 11/16" ...... just 3/16" to spare - not including tyre ....

The HR disc brake hubs on the front do not present any issue - except the clearance of the wheel over the caliper - many people have in fact gone to LH/X Torana calipers - they have one piston which is mounted inboard and affords quite a bit more room for the mount face of the hub to pass over....... read on - we'll get to the front in a later chapter......

The rear.... revisited....

Over the next few days, I spent many hours on my back under the car - with rulers, straight edges, levels, jacks and stands - lifting this, stretching that and for the life of my lack of intelligence - I could not conceivable find any way that either of these wheels were going to fit.....

Posts on the forum in the meantime were offering some comforting hope...... I must be the biggest dummy out - it is well beyond my intelligence on how you can fit a wheel and tyre (absolute stretch and almost vertical walled) requiring 3 5/8" into a clearance of 3 11/16" decreasing as it goes upwards.........

The next week I made the trek back to Kinglake and took many pix and measurements with me - resulting in confirmation that these would not fit the rear unless the body is altered to accommodate them........

I drove the poor chap mad....... questions, questions, questions... I could see that he needed to get back into the factory - he was absolutely daubed in alloy dust and "buff"....... but I must state - very hospitable and open to all suggestions......

Understanding my passion for these wheels - he offered me an option which I do not believe would have arisen if not for my persistence ....

It seemed they were going to do a run of 14 x 6 rims for our stud pattern the following week..... his offer... if you are extremely carefull - come and pick one of these up and take it home to trial fit it..... I jumped.......

This is the end of today's chapter folk....... stay tuned - there's heaps to come......

frats,

Rosco

chapter 3

Ok, just had lunch - one more little one for today or I'll fall over and you will loose interest (if not by now.....).

I spent a week playing with figures, looking at pix of cars and just about ready to walk away from the idea......

I'd left my contact number with Dragway and the call due on Monday didn't come...... the week was going downhill very fast - I looked at my old faithful 13 x 4 /2" steels with chrome trims and freshly coated (yes - another POR post coming - if I don't die first) hub caps....... I was just about over the dragway story and had it "boxed"......

Blocking back the radiator fan and feeling pretty happy with the POR Black on it - the phone rang....... "Ray Dunn from Dragway..... you can pick up the wheel - it's ready.....".......

fan down, garage locked and ...... off - like a shot out of a gun.......

We had quite a bit of a chat - he'd taken a good look at the pix and measurements...... "you're going to have to roll the rear lips.. I just don't know if there's enough room for a tyre - I know we've had people do this..... here's a picture of an EK ute - but these are the new version - you won't get the revised on unless you keep it jacked up, run 13's with low profiles or knock out the inners and roll the lips".

"I have machined off as much of the mount face as I can - if I take any more, you'll "press" the spoke into the drum outer face - I might have got you another 5mm ( this is new language for me - I like imperial ) - if it's a line ball - I can probably take another two - but that would be the absolute".

He gave me a few hints on how not to mark the wheel - "

it's the alloy centre you have to be careful with - if you mark it, I'll have to pull it apart and re-polish it"

"If you can get someone to carefully fit a tyre on it, you can keep it for a couple of days - do all your tests - if you go ahead and order - you'll have to take them, so be very accurate".

I wrapped the wheel up in a lambswool blanket and set off home again - round trip some 96 km's.......

I phoned a friend (where have I heard that....?) who runs a tyre store and asked if he could fit a 195/70 14" - "sure, when are you coming down?"

In about 30 mins...... OK?..... "um.........yeah, bring it on..."

I went out to the garage and fitted the rim to the rear........ I can't tell you how careful I was with this - masking tape on the nuts and washers - terry towelling to pick up the centre....etc, etc... etc...

As you can see..... my measurements were just about exact - there is a difference on the rear r/hs of only 1/16" - the l/hs being the more critical.

This rim is a 14 x 6 - my discussion with both Dragway and my rubber man has now convinced me it is going to be 14 x 7 - there will be more "draw" of the tyre across the additional inch..... so that the tyre wall bulges less...... you'll see - more pix soon..

Tyre fitted and back home again - I just didn't want to do this - I knew where it was going and didn't want to destroy the dream....

I had tea and it got the better of me.... sink or swim, crash and burn......

Wheel on - and at ride height it sat just fine - problems with throwing stuff up at the rear quarter panel - have to fabricate some new mud-flap mount - may put some super bright red LED's in there as additional brake lamps to that fitted to the rear window......... later....

got out the straight edge again and a texta pen...... disappointment and disbelief....... in all the measurements I'd made - it did not for one minute appear to me that the rear wheel-arch actually taper in towards the rear of the car...... this showed up when I "dotted" the texta where the straight edge showed problems vertically.......

As you can see - the dotted line runs deeper into the lip as it travels rearwards.

By now, my rubber man has arrived - very much intrigued by what's going on..... "hmmm - you're gunna have to knock it in - have you dropped it on the floor yet?"

I told him it was sitting at ride height - I had measured the suspension travel at 4" vertical until the axle housing reached the bump stop.

I explained that I would need to measure the difference in radius as the shorter front spring section arched forwards - all these things needed to be determined before I started to modify...... and these were 6" rims.....

I am about to jack under the front r/hs wheel to push down on the rear left - this should push the wheel up into the arch and put some weight on the lateral part of the spring......

"leave you to it - I'm off home to dinner"........

So - I did exactly what I told him...... and voila! - never going to be a problem..... as long as one wheel stays down........

Where I am going to have to do all this bashing (trust me - I am "inventing" method as we speak.... I may make a pair of "puckers".... small tools with narrow slots across them - to be used as "benders" - it may also come to purchasing a small hydraulic jack and using additional purchase from the suspension - I do NOT want to "bash" anything on this dear old thing....) is when both wheels bound upwards (humps, gutters etc.... you've all heard this happen when lowered cars have to negotiate all that seems everyday to the less promiscuous......)

So, loyal followers - this is where I'm with the rear - will have to now consider the wider rims for the front - I know there is going to be issue - 6"s were fine - these cleared the calipers like a soaring eagle..... 14"s just added that little "room"..... but as for the upper ball joints and tie rod ends...... we're off to the garage again this afternoon......

sick of this yet?........

frats,

Rosco

I spent a week playing with figures, looking at pix of cars and just about ready to walk away from the idea......

I'd left my contact number with Dragway and the call due on Monday didn't come...... the week was going downhill very fast - I looked at my old faithful 13 x 4 /2" steels with chrome trims and freshly coated (yes - another POR post coming - if I don't die first) hub caps....... I was just about over the dragway story and had it "boxed"......

Blocking back the radiator fan and feeling pretty happy with the POR Black on it - the phone rang....... "Ray Dunn from Dragway..... you can pick up the wheel - it's ready.....".......

fan down, garage locked and ...... off - like a shot out of a gun.......

We had quite a bit of a chat - he'd taken a good look at the pix and measurements...... "you're going to have to roll the rear lips.. I just don't know if there's enough room for a tyre - I know we've had people do this..... here's a picture of an EK ute - but these are the new version - you won't get the revised on unless you keep it jacked up, run 13's with low profiles or knock out the inners and roll the lips".

"I have machined off as much of the mount face as I can - if I take any more, you'll "press" the spoke into the drum outer face - I might have got you another 5mm ( this is new language for me - I like imperial ) - if it's a line ball - I can probably take another two - but that would be the absolute".

He gave me a few hints on how not to mark the wheel - "

it's the alloy centre you have to be careful with - if you mark it, I'll have to pull it apart and re-polish it"

"If you can get someone to carefully fit a tyre on it, you can keep it for a couple of days - do all your tests - if you go ahead and order - you'll have to take them, so be very accurate".

I wrapped the wheel up in a lambswool blanket and set off home again - round trip some 96 km's.......

I phoned a friend (where have I heard that....?) who runs a tyre store and asked if he could fit a 195/70 14" - "sure, when are you coming down?"

In about 30 mins...... OK?..... "um.........yeah, bring it on..."

I went out to the garage and fitted the rim to the rear........ I can't tell you how careful I was with this - masking tape on the nuts and washers - terry towelling to pick up the centre....etc, etc... etc...

As you can see..... my measurements were just about exact - there is a difference on the rear r/hs of only 1/16" - the l/hs being the more critical.

This rim is a 14 x 6 - my discussion with both Dragway and my rubber man has now convinced me it is going to be 14 x 7 - there will be more "draw" of the tyre across the additional inch..... so that the tyre wall bulges less...... you'll see - more pix soon..

Tyre fitted and back home again - I just didn't want to do this - I knew where it was going and didn't want to destroy the dream....

I had tea and it got the better of me.... sink or swim, crash and burn......

Wheel on - and at ride height it sat just fine - problems with throwing stuff up at the rear quarter panel - have to fabricate some new mud-flap mount - may put some super bright red LED's in there as additional brake lamps to that fitted to the rear window......... later....

got out the straight edge again and a texta pen...... disappointment and disbelief....... in all the measurements I'd made - it did not for one minute appear to me that the rear wheel-arch actually taper in towards the rear of the car...... this showed up when I "dotted" the texta where the straight edge showed problems vertically.......

As you can see - the dotted line runs deeper into the lip as it travels rearwards.

By now, my rubber man has arrived - very much intrigued by what's going on..... "hmmm - you're gunna have to knock it in - have you dropped it on the floor yet?"

I told him it was sitting at ride height - I had measured the suspension travel at 4" vertical until the axle housing reached the bump stop.

I explained that I would need to measure the difference in radius as the shorter front spring section arched forwards - all these things needed to be determined before I started to modify...... and these were 6" rims.....

I am about to jack under the front r/hs wheel to push down on the rear left - this should push the wheel up into the arch and put some weight on the lateral part of the spring......

"leave you to it - I'm off home to dinner"........

So - I did exactly what I told him...... and voila! - never going to be a problem..... as long as one wheel stays down........

Where I am going to have to do all this bashing (trust me - I am "inventing" method as we speak.... I may make a pair of "puckers".... small tools with narrow slots across them - to be used as "benders" - it may also come to purchasing a small hydraulic jack and using additional purchase from the suspension - I do NOT want to "bash" anything on this dear old thing....) is when both wheels bound upwards (humps, gutters etc.... you've all heard this happen when lowered cars have to negotiate all that seems everyday to the less promiscuous......)

So, loyal followers - this is where I'm with the rear - will have to now consider the wider rims for the front - I know there is going to be issue - 6"s were fine - these cleared the calipers like a soaring eagle..... 14"s just added that little "room"..... but as for the upper ball joints and tie rod ends...... we're off to the garage again this afternoon......

sick of this yet?........

frats,

Rosco

Rosco

You can get the gaurd lip rolled by a

body shop who will do a good job

or you can do it yourself and it will

be just as good if not better i did mine

about 15 yrs ago when i put my 13x7

dragways on i can take pics of the

rolled lip if you like and post them up or pm them to you

You can get the gaurd lip rolled by a

body shop who will do a good job

or you can do it yourself and it will

be just as good if not better i did mine

about 15 yrs ago when i put my 13x7

dragways on i can take pics of the

rolled lip if you like and post them up or pm them to you

EK JAY SINCE 1990

-

mrs ratbox

i'll throw a spanner in the works  i once had 13"x10" rims with 235x50 tyres on a very low sedan with only the lips bashed up

i once had 13"x10" rims with 235x50 tyres on a very low sedan with only the lips bashed up  it also had a HR diff, i've also seen plenty of FB/EK's with the "revised" rims more than likely with the lips rolled/bashed

it also had a HR diff, i've also seen plenty of FB/EK's with the "revised" rims more than likely with the lips rolled/bashed

i do believe different cars have different clearances, i have some 14"x7" chrome rims don't know the offsets with 215x65x14 tyres wouldn't fit on the van but i had them on the wagon and now on a sedan with no probs

rosco, i'm not trying to undermine you more backing up yor statement of this is based on YOR car

i do believe different cars have different clearances, i have some 14"x7" chrome rims don't know the offsets with 215x65x14 tyres wouldn't fit on the van but i had them on the wagon and now on a sedan with no probs

rosco, i'm not trying to undermine you more backing up yor statement of this is based on YOR car