Panel Repairs tips.

Posted: Sun Mar 30, 2008 9:23 pm

Hey Guys,

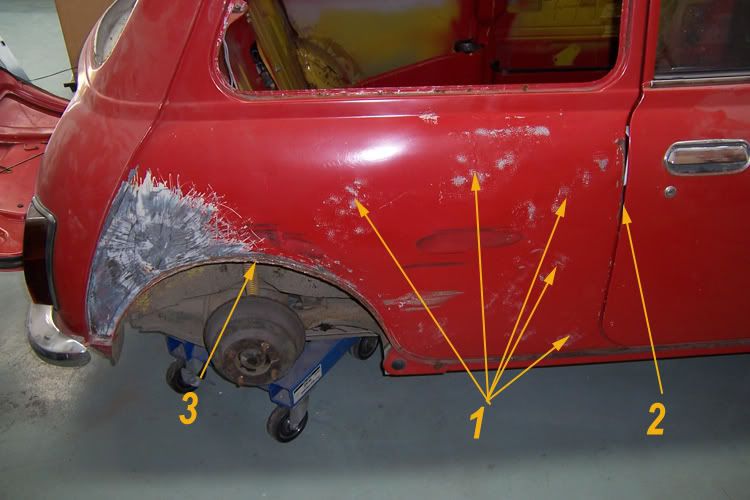

I thought I'd post a few tips on Body repair. I know it's not a FB or EK, but it's my mini, with some damage. The body I'm doing on this one will be the replacement for my rusted out yellow rocket that we have now.

Here you can see the dent in the roof the size of your palm where a tree branch has fallen on her. There are 2 large creases which I marked, where the roof has bent in and hit the roof support. I had to cut the roof support out to repair this area.

The first thing to do is to clean all the paint and primer from the area. I did this with the help of paint stripper and sanding disc on a 9'' grinder. The photo doesn't make the dent look that bad, but the crease is fairly harsh.

After clean up, you can see where you have to work the dent out, always start from the outside in, I used a hammer and dolly, for the exercise, you can buy a complete panel beating kit at Supercheap or elsewhere for a resonable price.

After working the dented area to a relatively flat surface, you can now see the slight imperfections. I used a slapper and dolly to smooth these out. A slapper is a tool that can be easily be made from a flat file, bent into a slight step shape with the use of an oxy to heat it before bending.

You use the dolly under all the low spots and hit the slapper, until you bump these lows up flush. ( a good tip is to blue ink on rag to wipe over the area) this will make those lows really stand out.

As you can see here from this shot. The roof panel is now flat and straight, after using the slapper to flatten the lows, I can then use a body file, to smooth over all the area, after doin this you may still need to bump a few lows, which I had to do. I then went over the whole repair with the sanding disc, to tighten the metal.

I thought I'd post a few tips on Body repair. I know it's not a FB or EK, but it's my mini, with some damage. The body I'm doing on this one will be the replacement for my rusted out yellow rocket that we have now.

Here you can see the dent in the roof the size of your palm where a tree branch has fallen on her. There are 2 large creases which I marked, where the roof has bent in and hit the roof support. I had to cut the roof support out to repair this area.

The first thing to do is to clean all the paint and primer from the area. I did this with the help of paint stripper and sanding disc on a 9'' grinder. The photo doesn't make the dent look that bad, but the crease is fairly harsh.

After clean up, you can see where you have to work the dent out, always start from the outside in, I used a hammer and dolly, for the exercise, you can buy a complete panel beating kit at Supercheap or elsewhere for a resonable price.

After working the dented area to a relatively flat surface, you can now see the slight imperfections. I used a slapper and dolly to smooth these out. A slapper is a tool that can be easily be made from a flat file, bent into a slight step shape with the use of an oxy to heat it before bending.

You use the dolly under all the low spots and hit the slapper, until you bump these lows up flush. ( a good tip is to blue ink on rag to wipe over the area) this will make those lows really stand out.

As you can see here from this shot. The roof panel is now flat and straight, after using the slapper to flatten the lows, I can then use a body file, to smooth over all the area, after doin this you may still need to bump a few lows, which I had to do. I then went over the whole repair with the sanding disc, to tighten the metal.