cruisin_doug wrote:Thanks Craig and Rosco, there are many opinions on this subject as I am finding out ... probably the biggest thing for me is no one can really spell out the

benefit of disconnecting the vacuum advance, the advocates of doing so just say it doesn't work properly because of low vacuum when running a cam etc - but what would be the

gain of disconnecting it rather than getting a vac can that operates at a lower vacuum if necessary (lighter spring??)?? From what I have read Vac advance can't hurt WOT performance as there is no vacuum under those conditions - so it comes back to a drivability thing.

Craig I have also read that the vacuum advance is better connected to

manifold vacuum ...

Interesting thread on vac advance

Reading through that thread he says that the vacuum advance only started being connected to port vacuum in the pollution control era ... but if my memory serves all the earlys have always had the vac advance connected at the base of the carby ??? Not sure if the stock connection is above or below the throttle plate

You posted as I typed this Rosco - is the stock connection into manifold vacuum????

Any thoughts on connecting to manifold vacuum rather than port vacuum????

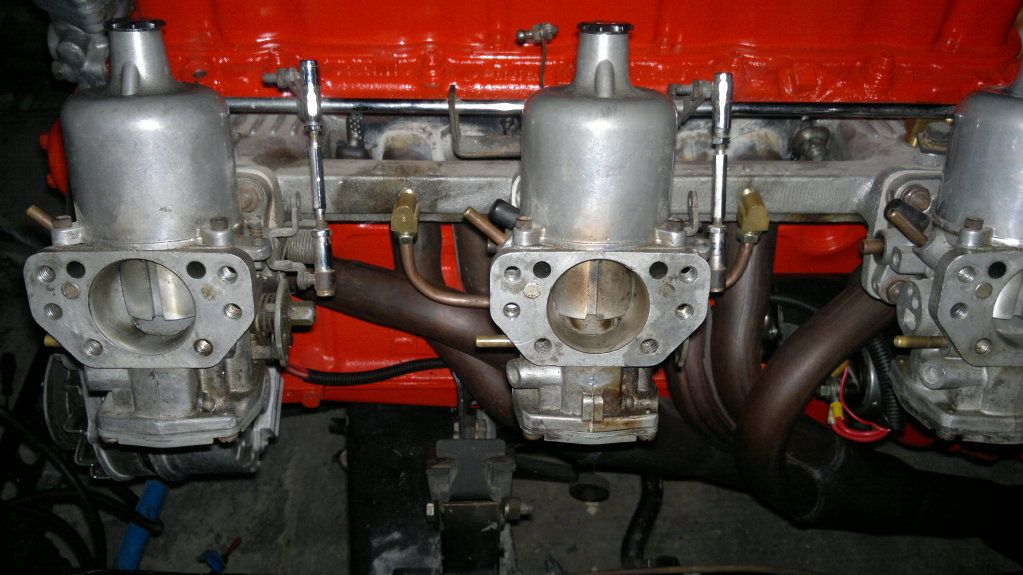

I am also incorporating PCV into my engine this time around - after much research and about a million questions I ended up using a dual tap into the balance tubes between the carbies as was done in the XU-1 days:

I am running a three hole rocker cover, with the pressure relief line into a boss on the tube just below the air filter (after the filter, before the carb) on one carb only. I will obviously need to get the carbs set up again to suit, so I wanted to get the vac advance question settled before doing so.

Hmmm ... I am thinking I will be reconnecting it and see what happens - the guy that tunes my carbies (excellent carby guy - Mike from Dual Fuel in Caboolture) certainly prefers it to be hooked up! I only actually went to the dyno guys to get the distributor regraphed as I went for the HEI one and wanted it set up to suit the cam ...

Any thoughts on running a lighter sprung vac advance pot (if there is such a thing) to compensate for the cam???

Can anyone recomment someone that does distributor recurves and could make sure the vac advance is set up correctly??

Thanks for your thoughts on this guys!

Doug

Hi Doug,

I can feel a "War & Peace" epic coming on but I'll try and keep it short.

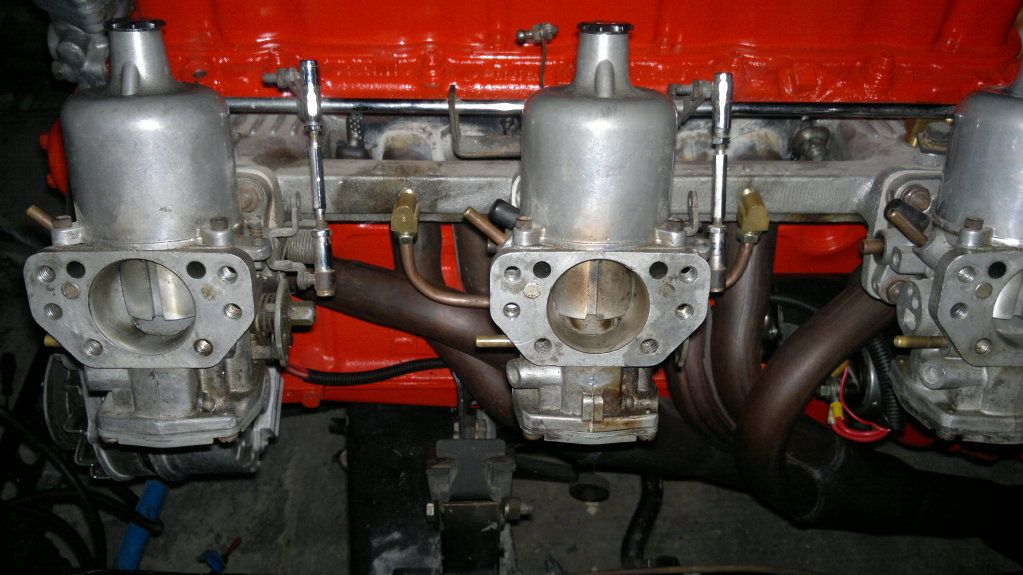

Some time back I went thru the same issue trying to get a distributor recurved for a straight gas set up on a 186 shown below.

IMGP32352.jpg

I got the same treatment regarding vacuum advance not being needed and after a while of stuffing around I started to realise how poor the standard distributor system was.

Intial testing showed the "recurved" dissy was so far out it wasn't funny. The intial base timing was set to 6 degrees but this proved to be to far retarded for the fuel and appears to have only been done to get the idle down to 600rpm due to an oversized throttle body in the gas carb, and to get the engine to turn over reasonably when starting (high compression). At idle I could adjust the intial advance to around 20 degrees and the engine would run really well at idle, but struggled a bit on cranking on start up (as expected with the high comp). I also fitted a fuel ratio meter a discovered the carby system was running excessively lean during progression to the main metering system, then it would go over rich after that.

I then got a timing light that had a advance adjustment dial on it and checked the mechanical advance curve from idle up to 5000 rpm at 100 rpm increments. Then I did the same again but readjusted the distributor at each 100rpm point to see if I could get an increase in rpm. If I got an increase or decrease I would adjust the timing and plot this new setting on a graph.

In the end the two plotted ignition curves where miles apart. That was it for me. As far as I was concerned "recurved" distributors were not the way to go if I wanted decent performance and economy.

In essence the mechanical advance curve of a distributor is reasonably linear whilst an engines breathing ability isn't (depending on camshaft). To add to the problem, vacuum advance rates need to be altered becuase of the change in fuel burn characteristics and different load conditions that engine is now operating under after being modified.

For me I decided to build a direct fire ignition system i.e. camshaft and cranshaft sensors, Map sensor, and individual coil per cylinder, that coupled with a closed loop injection control would solve all my problems.

Now back to your question regarding using manifold vacuum for advance control,

I wouldn't do it.

Firstly if you did this you would have full vacuum advance at idle which isn't needed due to idle mixtures being somewhat richer then, especially if longer than standard duration camshaft is being used. You may also find that using manifold vacuum as a source of advance that you will have erratic timing control and will cause excessive wear on the breaker plate due to manifold reversion from the camshaft. I have tried using manifold vacuum as a source and found it caused an off idle flat spot and was way too sensitive. You also either had all vacuum or nothing through the rev range. The only time it sat reasonably steady in change was during cruise conditions. As I stated before, ported vacuum helps with the lean out condition when cracking the throttle from idle. If you went with manifold vacuum it would retard the timing in this case.

Do yourself a favour and get a vacuum guage and hook it into the vacuum line to the dissy. Do a trial on a car set up with ported vacuum, then if you can, replumb it to manifold vacuum. First thing you'll notice is the idle will be too high and you may struggle to get it down withing limitations of the carby stops. If that doesn't work, most retard the distributor timing to do the same and that just stuffs the timing up for the whole rev range and from then on your back in the same shitty mess but worse. The one thing this test will show is how different the two vacuum sources do operate under real conditions, not just idle.

I would stay with ported vacuum if your going to stay with the distibutor. There are adjustable vacuum advance pots around but I haven't seen one for a red motor. Have a look at this website

http://www.performanceignition.com.au/home I have seen them do some good stuff as far as mods for ignition systems, stuff like grafting a holden HEI dissy to suite a grey motor. They should be able to help out with an adjustable vacuum pot for your dissy.

With the vacuum advance pot it wont be perfect as it will be difficult to sort what will be right without putting the engine on a dyno again. You'll have to see if you've got the right amount of advance travel and the right advance rate (spring tension).

Once my system is built I will be putting the engine on a dyno to replot/Map my igniton system at the appropriate load points throughout the rev range. In my opinion there is no other way to do it.

Re "Reading through that thread he says that the vacuum advance only started being connected to port vacuum in the pollution control era ... but if my memory serves all the earlys have always had the vac advance connected at the base of the carby "

The vacuum advance port has always been at the throttle base (port is just above throttle plate when at idle), not at the manifold on early Holdens. I've never heard or seen "vacuum advance only started being connected to port vacuum in the pollution control era" but I could be wrong

Oh, I nearly forgot, does your SU carbies have a ported vacuum connection to hook into??

And you mentioned your's was dynoed? Was it Chassis or engine and what type of dyno test did they do? I had mine done on a chassis dyno the first time around but it was adjusted, given a burst run, adjusted again, and so on. Totally crap as far as I'm concerned.

After a I went thru all this with my set up I realised that I was trying to map a fuel and ignition curve by trying to modify mechanical fuel and ignition systems. Engineers at Holden probably have spend millions developing their systems but I was going to reinvent the wheel anyway.

Suddenly my brain kicked in and I discovered these things called ECU's

Lessons learnt from all this, go full electronic if you want to strive for perfection, or stay stock if your happy to put up with it being not so perfect. Its all about choice I guess!

Cheers and good luck.

Craig.