Finally managed to get home from work, sorted some life stuff then on to the FED.

The original Repco pushrods are needle thin. The new rockers are made for sturdy 5/16" ball end ones. The lifters needed to have the cups machined out to suit the bigger 5/16" pushrod ends. I had sent them off before going to work. They were waiting for me when I got home with a warning - several of the lifters were not real good, and two of the cups too. I had not looked at them very hard when I pulled them out of the speedway motor... it was running, so assumed OK. Stupid me. Sure enough they were pretty hairy... the scratches I can live with, but the chips and circumferential grooves not so much. Managed to source some cups, and sent off a set of lifters that to get them machined for the cups. These are good lifters that Clive refaced for me years ago.

While the lifters get done, on to the pushrods. I have enough good lifters to dummy up. Need the cam on the base circle, so try to turn motor over. Remembered that engine and box had locked each other. Arm wrestle the box back a bit, and finally get it to turn again.

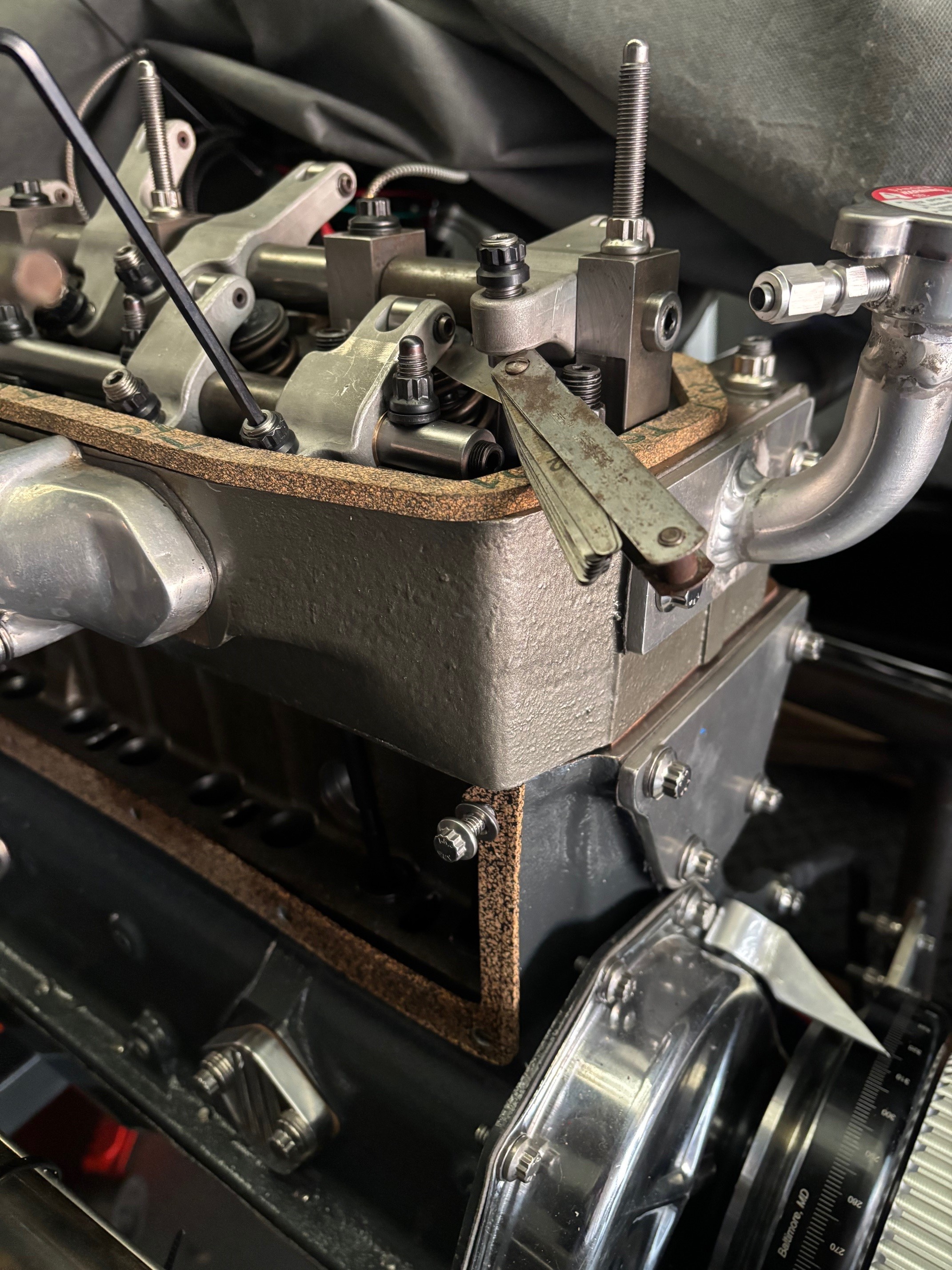

Sideplate off, rocker cover off and fit the Comp Cams pushrod checker to the inlet side. This is where having the FED at Kennards is not great... forgot the allan keys to adjust the rockers, so home again (lets see how many times I forget something and have to go home). Rockers off, adjustable pushrod down the hole, rockers back on. 14 thou feeler under the roller tip to simulate lash.

- rockers.jpg (1.26 MiB) Viewed 5194 times

Expand the pushrod checker by screwing it out. Just enough that it won't spin, not so far that it starts to lift the valve.

- adjustable.jpg (932.41 KiB) Viewed 5194 times

Then use some masking tape to hold the checker so it doesn't wind in/out while I remove it.

Masking tape. Crap. Forgot that too. Thats twice.

Tape found, remove rockers, pull out taped checker. All good so far.

Repeat process for exhaust side (this time I have allan keys and tape!). Find out that the pushrod checker I bought is too long. So, so close, but too long. They come in 1" increments. Order another checker, but one size down.

While waiting for the new checker, I can at least measure up that taped inlet checker. Trend pushrods measures their length in an unusual way. Because the pushrod tip is affected by the oil hole, they do not measure overall length. Instead, they measure their pushrods by placing a washer over each end. The washer has a 0.140" hole in it, that overcomes any oil hole shennanigans. Measure between the washers, subtract washer thickness, and you have the "0.140" gauge length" that Trend uses.

I got cute and ordered some 0.140" ID washers before going to work. Come home, and no washers. Check eBay, emails, Amazon etc... no idea where I ordered them. Figured I was getting CRAFT, so start again. Went through the big tin of washers, found two that were close, reamed them to 0.140". The kids then dropped off parcels they had forgot to bring over... including the washers I had bought. Sigh.

Measure the pushrod, and get 6.3505".

- measure.jpg (1.8 MiB) Viewed 5194 times

Measure the two washers, and get 0.03". So the inlet pushrod I need is (6.3505-0.03=) 6.3205". Trend does 6.3 or 6.35, so will go with 6.35".

More waiting... time to start thinking about why that 'Glide wont mate up properly.

Cheers,

Harv