Bit of a deep dive into my rotisserie build.

Learnt a few things too. That’s my positive spin on making mistakes.

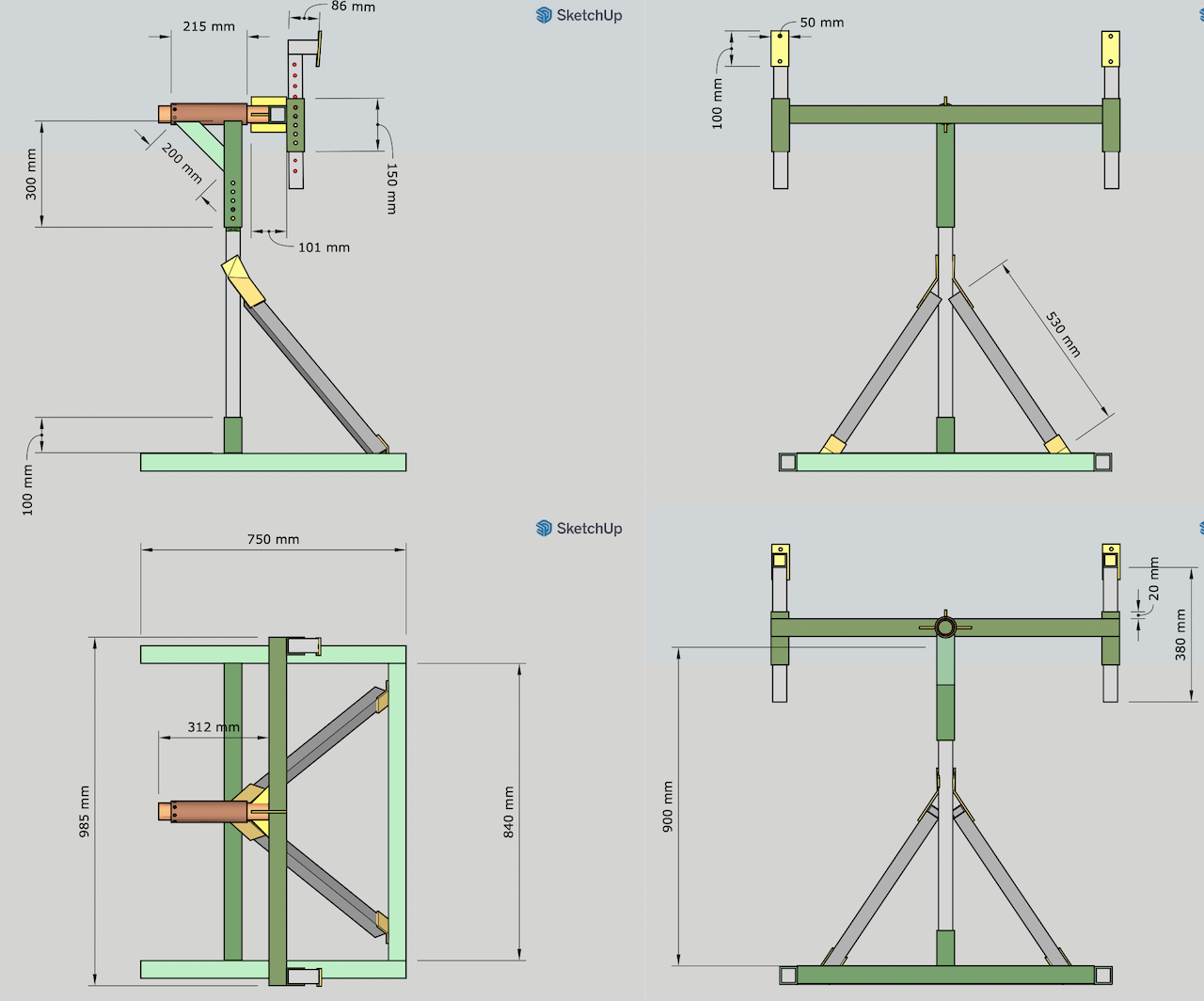

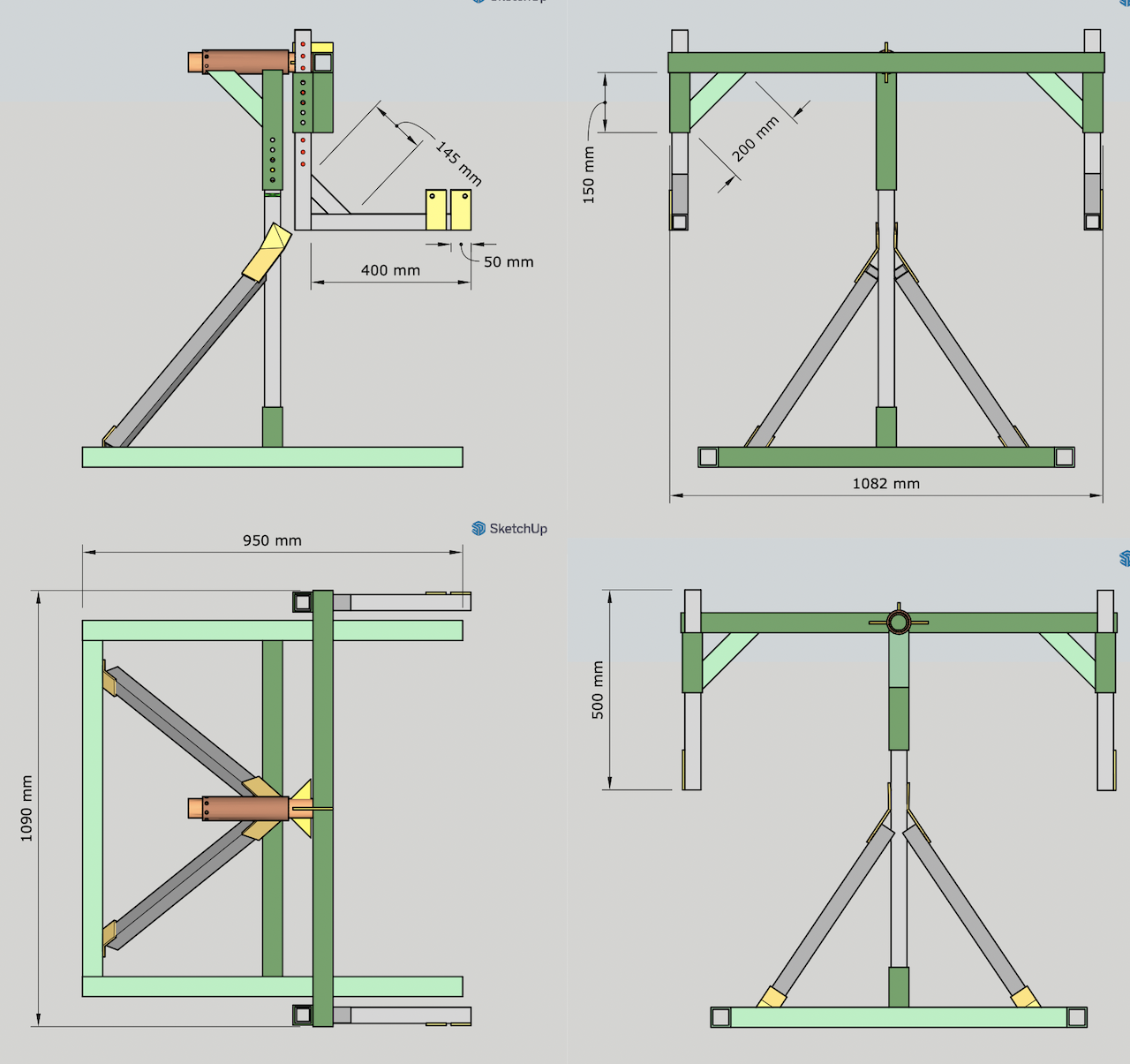

First up, spent a lot of time in Sketch Up trying to design something that was strong, and used minimal materials. My local steel stockist sell at a reasonable price for full lengths, but as soon as you cut a length, you pay for the cut and the price per meter goes up. So was working to squeeze everything out of two lengths of 8 mtr (40 x 4 and 50 x 5). Couldn’t do it - at best I was going to have 20mm waste and that left no room for error and way too much stress. In the end settled on an additional length of 50 x 2.5 which meant I could extend the base to offer a bit more support.

The are also 8 brackets, 6 mounting plates, various bracing for the main beams, all cut from one length of 50 x 5 plate, and inner and outer steel pipe CHS with the thickest wall section. Those will have to be cuts as I only need under a metre of each

So jigged and re jigged, and came up with these final designs.

- Front.png (894.81 KiB) Viewed 3171 times

- Rear.png (1.36 MiB) Viewed 3171 times

Few tricky things to to here. Brackets are all bent so have to work out how to do that without oxy torch. All the holes are for adjustment. They work like a veriner caliper scale, so everything can be adjusted 5mm within a 140mm range. The outer pipe has 4 holes (pic shows more but realised after 4 the pattern repeats) at 0, 22.5, 45 and 67.5 degrees. Inner pipe has 6 holes all at 60 degrees. From that I should be able to spin and lock it at 15 degree increments. Do I need that level of adjustment? Probably not. Is it over kill? Hell yes! But was fun to work this out.

So placed my steel order $500 delivered (which was $110), then puzzled over if I should buy a cut off saw of hire one from Kennards. $70 to hire for a day, $210 to buy and have it delivered to my door. Decision made.

- IMG_8980.JPG (596.92 KiB) Viewed 3171 times

Note the old used fire blanket as spark arrester. This is getting a lot of use when I grind things.

Steel arrives, I help the guy unload, he sees the cars and wants a look as you do. Ex panel beater. Extolling the virtues of fish oil. Unfortunately that was about all the advice he could offer up.

Sent him on his way and first lesson is discovered. Despite multiple price checks and aborted orders on the steel website, when I finally put in the order I selected the thin wall CHS pipe for the outer so the inner one is rattling around. Grrrr, re order BOTH inner and outer as I decided the inner one should be thicker as it will bear a lot of the weight.

Picked up new CHS and figured I start on the holes. Measured the diameter of the pipe, got out the calculator. Marked the six points out and wrapped my guide round the pipe ready to hole punch

- IMG_8968.JPG (526.74 KiB) Viewed 3171 times

Well actually that was take two. My first attempt I drilled straight though thinking that my $100 drill press was square and my centre punch perfectly lined up. Neither were. With the additional holes drilled the final result was comical at best. My dad is and ex fitter and turner. I’m sure it would make him proud.

Decided to thread the inner pipe for an M8 bolt. Don’t want the pin coming out. This was before I realised I only need 4 holes on the outer pipe and gravity would do just as well. Way I kept the tap square…..

- IMG_8969.JPG (561.51 KiB) Viewed 3171 times

Same approach and I have 4 holes in the outer.

- IMG_8982.JPG (676.75 KiB) Viewed 3171 times

Fit is a bit sloppy but I think it will do.

- IMG_8981.JPG (768.75 KiB) Viewed 3171 times