Page 15 of 25

Re: Harv's FED thread

Posted: Thu May 30, 2024 2:41 pm

by Harv

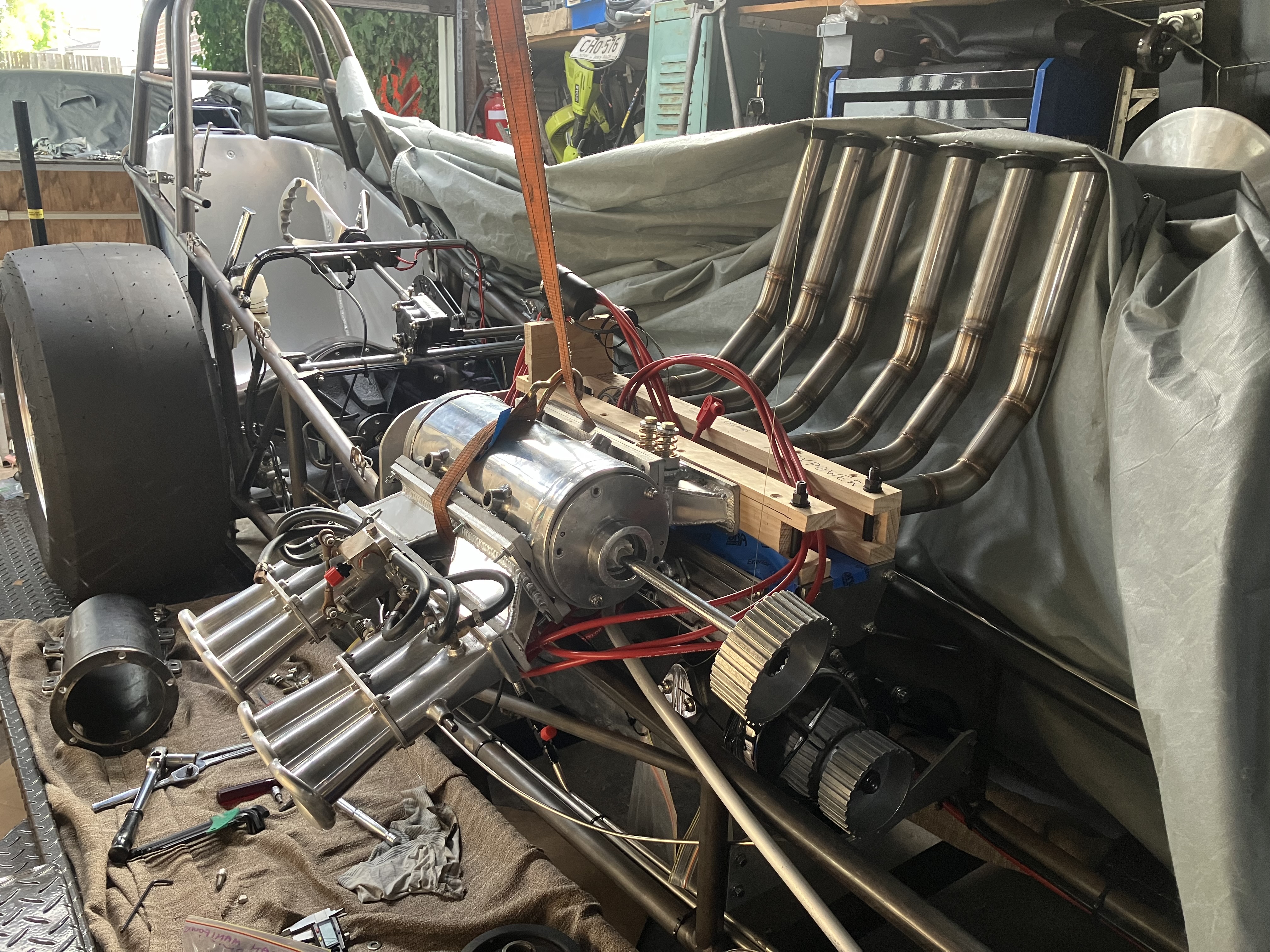

Optional NASCO orange skyhook shown to complement the three particle board screws used to mount the assembly to the wooden dummy head.

- IMG_1216.jpeg (3.24 MiB) Viewed 1681 times

Cheers,

Harv

Re: Harv's FED thread

Posted: Thu May 30, 2024 3:11 pm

by Brett027

That's a very long and lonely shaft Harv

Re: Harv's FED thread

Posted: Thu May 30, 2024 3:32 pm

by Blacky

Re: Harv's FED thread

Posted: Thu May 30, 2024 6:22 pm

by Harv

Brett027 wrote: Thu May 30, 2024 3:11 pm

That's a very long and lonely shaft Harv

The Norman shaft is about 4” too short. I need to get it cut off, and a new shaft added. Similar job to what one of the Taswegian humpy boys did not long ago on a Type 65. I have a bloke locally that I think can do it. It will need a plumber block bearing to stop the belt tension bending the supercharger. This is the price I pay the get the Norman dead-center into the Repco inlet ports.

This project is not a good idea. Lots of stuff at once - FED, weird rear main seal, too overbored, Repco, supercharging, injection, dry block. Getting it all to work together is going to be a crap fight.

But there is a bunch of guys keen to help me iron out the crap where I am ignorant.

In the meantime, I keep grinning like a Cheshire Cat

Cheers,

Harv

Re: Harv's FED thread

Posted: Thu May 30, 2024 8:58 pm

by FireKraka

Re: Harv's FED thread

Posted: Fri May 31, 2024 12:25 am

by Errol62

One way or another it will $*#@ bang!

Sent from my SM-G781B using Tapatalk

Re: Harv's FED thread

Posted: Fri May 31, 2024 8:18 pm

by BS

Damn Harv!!

Sent from my iPhone using Tapatalk

Re: Harv's FED thread

Posted: Fri Jun 07, 2024 7:22 am

by Harv

Spoke to Head Stud Development yesterday. The Repco head is nearing completion - general tidy up, sort out the multiple spring seat depths, new exhaust valves, additional shaft supports, new springs, retainers and collets, install and fettle rollie rockies. Should be done by the end of the month.

Once it's done, the head can have a small holiday in WA. Off to Galloway engines to have a receiving groove cut into the head. This will match the grooves they have cut in the EKMart engine block and allow six steel o-rings to be run for the head gasket. Should help stop the Norman blowing out the head gaskets.

After that, either bring the head home on it's own, or mate it to the short block and bring home as a long motor.

Cheers,

Harv

Re: Harv's FED thread

Posted: Tue Jun 18, 2024 4:29 pm

by Harv

Learned another useful lesson today...

Harv wrote: Sat Apr 13, 2024 12:53 pm

Hardness Material

1 Talc

2 Gypsum

3 Calcite

4 Fluorite

5 Apatite

6 Orthoclase feldspar

7 Quartz

8 Topaz

9 Corundum

10 Diamond

11 ARP bolts

12 #10-24 tap snapped off 1" into a piece of aluminum

892 Snapped-off Eziout

Drift it through, Helicoil the mess.

Cheers,

Harv

Re: Harv's FED thread

Posted: Mon Jun 24, 2024 11:26 am

by Blacky

Re: Harv's FED thread

Posted: Mon Jun 24, 2024 3:00 pm

by Harv

I needs to find me a stunt double for those photos... I've got a face like a dropped pie

Cheers,

Harv

Re: Harv's FED thread

Posted: Mon Jun 24, 2024 6:48 pm

by Blacky

Re: Harv's FED thread

Posted: Mon Jun 24, 2024 8:00 pm

by In the Shed

Good job Blacky, did you pick up any go fast grey gear for the Ute?

Re: Harv's FED thread

Posted: Mon Jun 24, 2024 8:04 pm

by Blacky

Harv is in the business of procuring grey motor goodies, not disposing of them .......

Re: Harv's FED thread

Posted: Tue Jun 25, 2024 10:27 am

by In the Shed

weather was pretty awful so the wagon,sedan and ute stayed wrapped up though

weather was pretty awful so the wagon,sedan and ute stayed wrapped up though