Page 2 of 5

Re: DIY Rotisserie

Posted: Sat Jul 31, 2021 7:51 am

by funkyscooter

ardiesse wrote: Fri Jul 30, 2021 2:19 pm

Scott,

You've found the rear bumper mounts. They take 3/8" bolts, but I can't remember whether UNC or UNF.

And the threads in the captive nuts frequently get chewed out, or the bolts break off inside.

Rob

That's so funny (and embarrasing). Of course it is - and that's what the tow bar was attached to.

Thanks for the heads up on the bolts.

Re: DIY Rotisserie

Posted: Sat Jul 31, 2021 7:57 am

by funkyscooter

Thanks for the pics Clay and Brett. Original plan was hangers but two bolts much better than 1. My son is still laughing about the bumper mounts......

Re: DIY Rotisserie

Posted: Sat Jul 31, 2021 10:59 am

by Brett027

I am not convinced about 2 bolts being better than 1. One gives you a pivot and some flex/give.

You don't need much strength either. The whole empty shell only weighs about 400kg. That's only 100kgs on each corner. Rotisserie just needs to allow you to turn the shell without twisting it and without hitting anything on the way 'round.

And you don't need shell to do 360°. 90° both ways and 180° one way gets you what you need.

Re: DIY Rotisserie

Posted: Sat Jul 31, 2021 1:00 pm

by funkyscooter

Interesting. 400kg does not sound like much. Still have the springs on at the moment so if I can mount the rear off the bumper then all good. Will be mounting on rubber to give a bit of flex.

Question - what is the thickness of peoples rotisserie box section. I was looking at 50x50 5mm wall thickness, but at 400kg that feels like overkill. 4mm?

65 x 35 4mm rectangle box section is roughly the same price as 50x50x5.

My crap ebay engine stand is 2mm.

Re: DIY Rotisserie

Posted: Sat Jul 31, 2021 5:29 pm

by DaveEK

4mm will be more than adequate for a rotisserie. Do you need flex on a rotisserie?

I have welded a rotisserie to chassis rails before and never had an issue

Re: DIY Rotisserie

Posted: Sat Jul 31, 2021 6:37 pm

by Errol62

The 65x35 will have same shear strength as the 50×35 in the vertical anyway.

I used a combo of 75x50 3mm and 40x40 4mm. Basically what ever came to hand.

FB ute driver, EK van project

Re: DIY Rotisserie

Posted: Sun Aug 01, 2021 5:40 pm

by Brett027

Yeah I'm with Clay. 3mm fine and 4mm is plenty. More important to get the bracing, design and welds right I reckon.

Maybe my flex thing is unnecessary too. On mine (and others) there has been an issue of posts angling in. If there was no flex/ movement on the mounts, maybe there would be less post strain towards the centre.

Anyway I've now broken my own rule about not overthinking rotisseries

Speaking of which I would be keen to hear how you can test mount a kframe on a car that is already on a rotisserie. Oops, I did it again...

Re: DIY Rotisserie

Posted: Sun Aug 01, 2021 8:28 pm

by Errol62

Keep the mounting inboard of the hinge positions is all that is necessary really Brett. Have a look at my van build if you can be bothered. I put subframe on with the body upside down to dummy up the inner leg mounts and number one body member.

FB ute driver, EK van project

Re: DIY Rotisserie

Posted: Sun Aug 01, 2021 8:47 pm

by Brett027

Thanks Clay. It depends on your rotisserie if you can do that. The post structure on my one wouldn't allow it. For me inner sill and kframe alignment was done on jack stands before putting bod on rotisserie to finish off welding the sill and do the floors etc. Whatever works to get the alignment right.

Re: DIY Rotisserie

Posted: Sun Aug 01, 2021 10:38 pm

by Errol62

Yeh you dont need it brett. What's ever works innit?

FB ute driver, EK van project

Re: DIY Rotisserie

Posted: Mon Aug 02, 2021 5:58 am

by DaveEK

Brett, where are you located I may know someone who has a rotisserie that you could get cheap and just modify the arms to suit? Would be a lot easier. I’ll have a chat with the guy today

Re: DIY Rotisserie

Posted: Mon Aug 02, 2021 7:22 am

by Brett027

Thanks Dave. I'm right for a rotisserie. Will be selling mine after next 2 utes are done.....

Re: DIY Rotisserie

Posted: Mon Aug 02, 2021 8:49 am

by funkyscooter

DaveEK wrote: Mon Aug 02, 2021 5:58 am

Brett, where are you located I may know someone who has a rotisserie that you could get cheap and just modify the arms to suit? Would be a lot easier. I’ll have a chat with the guy today

Hey Dave, thanks for the offer (I think you meant me!), not sure I can squeeze one onto my hoist though. The ones I have been looking at are all too wide at the base. Happy to get some dimensions to see if it would work.

Located on the Northern Beaches.

At the moment, based on some rough ideas, I'm looking at around $400 for the metal (inc delivery @ $110).

Thanks

Scott

Re: DIY Rotisserie

Posted: Mon Aug 02, 2021 6:04 pm

by DaveEK

Haha sorry mate I’m just jumping through posts. I had a chat to him today he’s getting measurements for me tonight I’ll let u know

Re: DIY Rotisserie

Posted: Wed Sep 01, 2021 5:16 pm

by funkyscooter

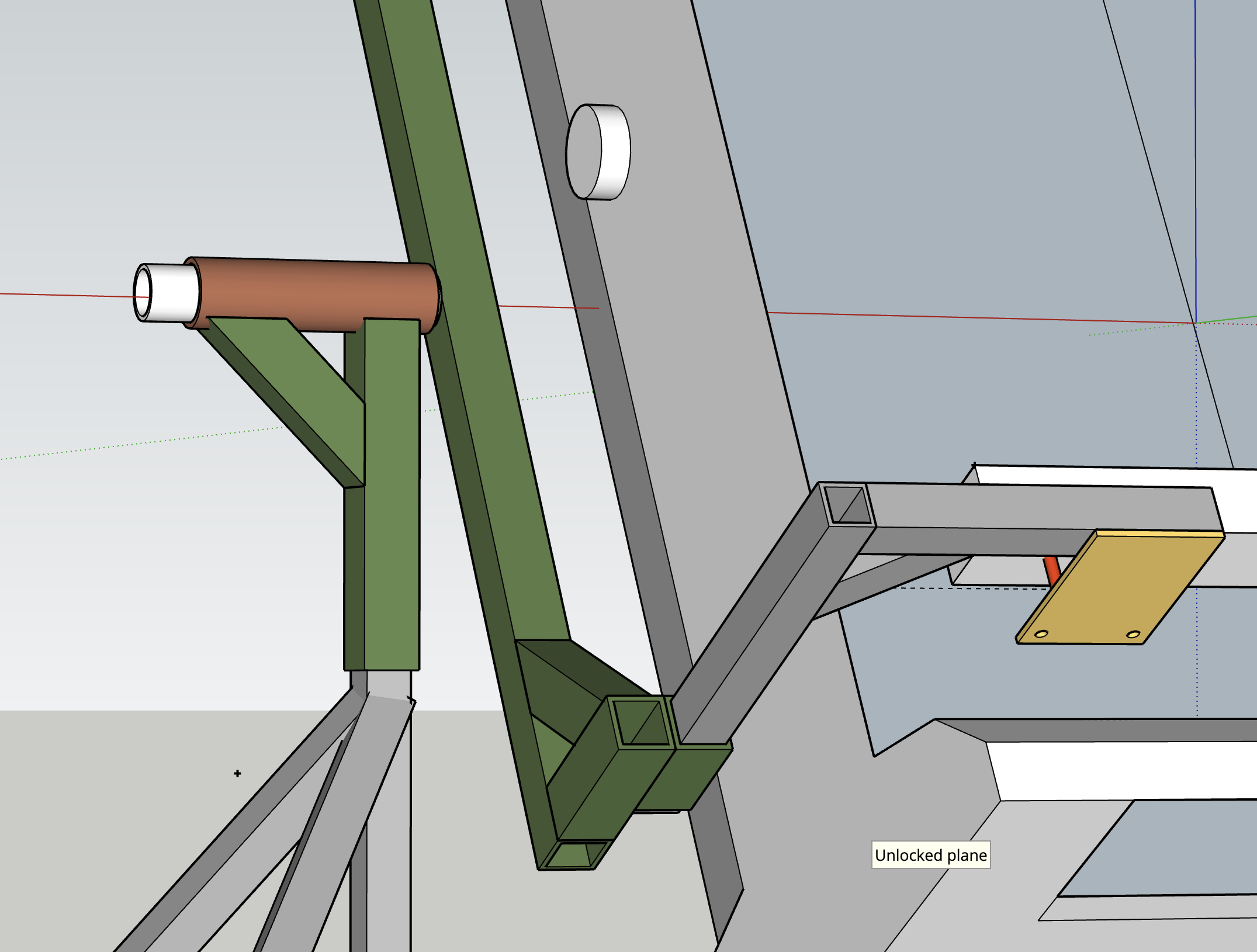

So me and my new ‘friend’ Sketch Up have been hard at work.

Took lots of measurements of the car, then took some more, then remeasured when I still didn’t think the numbers were right. They are all guide at this stage to work out material costs and feasability, but most are pretty close.

Ended up with this.

- Side.png (240.88 KiB) Viewed 5083 times

- Rear Spun.png (386.41 KiB) Viewed 5083 times

Although both braces are pointing to the rear I don’t think that will be an issue. Should not be much front to aft movement

There is enough adjustment to go from a centre of gravity at the firewall seam which lines up with the fuel cap at the back….

- 34 Front Low.png (253.71 KiB) Viewed 5083 times

- 34 Rear Low.png (267.69 KiB) Viewed 5083 times

… and if need be can be adjusted to about 40mm below the bottom bonnet hinge bolt at the front, and 150mm above the fuel cap centre

- 34 Front High.png (763.83 KiB) Viewed 5083 times

- 34 Rear High.png (442.23 KiB) Viewed 5083 times

The Green section below the pivot can be raised if needed. Green SHS is 50x4, Grey SHS and the red base is 40x4. Pivot inner is 40 NB HBPE (48.3 x 4mm), and pivot outer is 50 NB HBPE (60.3 x 4.5mm). Yellow mounting plate is 50 x 150 x 6mm front and 150 x 112 x 6mm rear

- Front Tight.png (164.46 KiB) Viewed 5083 times

- Rear Tight.png (278.12 KiB) Viewed 5083 times

Can’t say its been easy using Sketch Up but I have learnt a lot. My next “task” is to re design the kitchen!