Parisian62, got nothin to do with luck man! i've worked hard for it and gone with out a lot of things to get it

Underside is getting there. Re-routed the fuel and brake lines over the new chassis rail, threw away the old clip thingo's and used nutserts and P clips. New rear brake hoses, ran new rear lines etc. Handbrake and speedo cable mods done.. The list is getting shorter and shorter

Under full suspension travel, the hoses came pretty close to the inner tub so i decided to move them inside the bleed nipple instead of curving around. On one side we just drilled another hole in the hose fitting and relocated the pin but on the other side we had to actually sink a small hole into the back of the caliper to move it inside.

To keep things a bit more era, i bought a set of twin strombergs on a finned manifold. Also got a finned rocker cover thanks to Andy and some finned side plates from the old man. Pics to come........

I POR15'd the floorpan. The instructions are a little hard to understand so i thought i'd post up how i did it for anyone else that might go down this track one day.

The POR is a rust converter, preventer and permenant paint coating in one. It can be applied with a brush or out of gun but i just used a brush (it flows out to a near sprayed finish anyway, plus you'll never see it on a floorpan). You can smash it with a hammer and it wont chip, crack or peel. Pretty good stuff. USE GLOVES! basically you have to hit it with thinners instantly or only time can remove it.

I did the complete 3 stage process, marine clean, metal ready then POR. If you sandblast your floorpan or any other surface that you are going to POR paint over, then there is no need to do the marine clean and metal ready, sandblasting is the ideal preparation but as we all know it leaves a hell of a mess and i didnt want grit falling out of my car for the next 5 years.

First i welded up any large pinholes then bare metaled the floor with a wire wheel on a grinder, painstaking process... literally. I learnt that thin shorts with little protection and wires breaking off the wheel meant youd soon be in tears, pulling stray wires from your ball bags. Not fun.

Once bare metal'd i then applied the marine clean (diluted approx. 10-1). I used a spray bottle to apply it then brushed any puddles around.

You leave it for approx. half an hour and then i cleaned it off with a wet rag and water (i got told to use bottled water due to the contaminants in tap water), once the marine clean is removed, it has to be dried thoroughly. There should be a noticable difference in the appearance of your floor. It should be cleeeean!

I then applied the metal ready (straight/undiluted), just like the marine clean i applied it with a spray bottle then brushed around any puddles.

Again, its left for approx. half an hour and cleaned off with a wet rag and water (you wont remove the coating, only the excess) then dried thouroughly. The metal ready leaves a 'toothed' zinc phosphate coating which helps the POR paint adhere to the floor. It will have a salt and pepper look along with some orange-surface rust looking areas but thats normal!

Paint time

Now your floorpan shouldnt rust! EVER!

Adapted the Commodore rear handbrake cable to the EK front one.

To get it to pull straight we spaced the pulley out about 100mm from the subframe. It slides over the seams and bolts to the subframe.

I Welded the pivot bracket thing to the gearbox crossmember and also recessed a tube in there for the speedo cable.

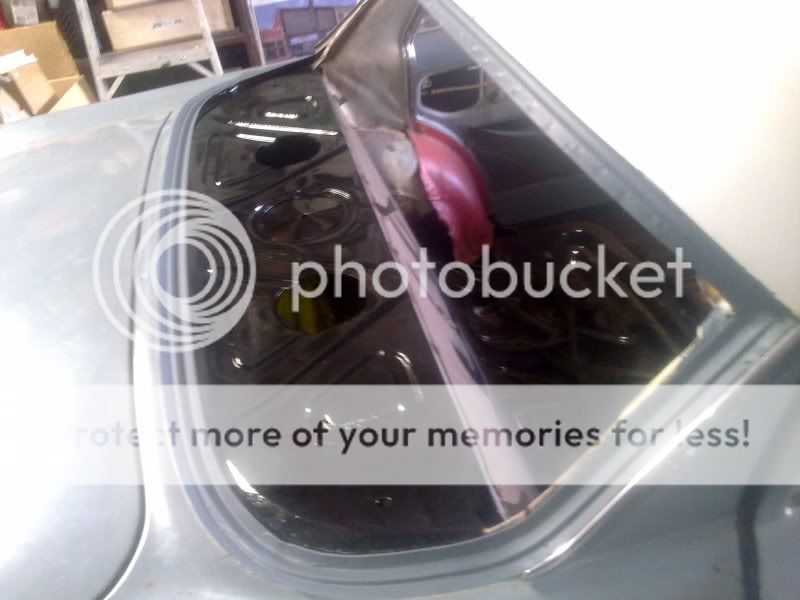

I popped the front and rear screens... no worms, pretty good nick, i pulled it back to steel, POR'd it then primed over that.