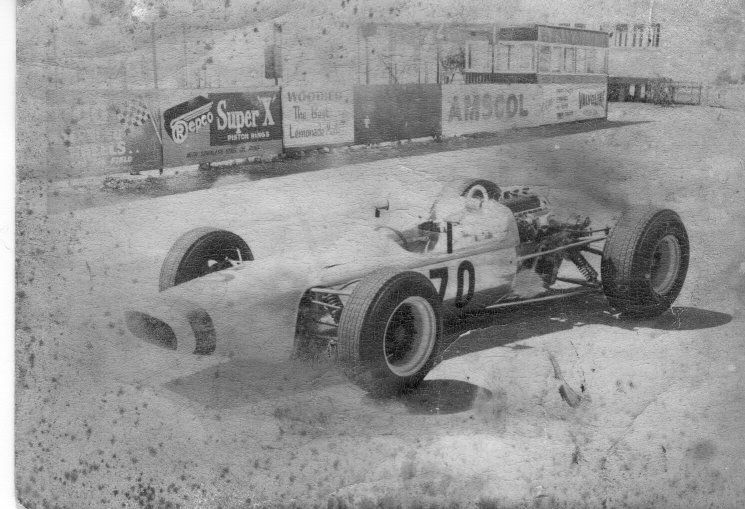

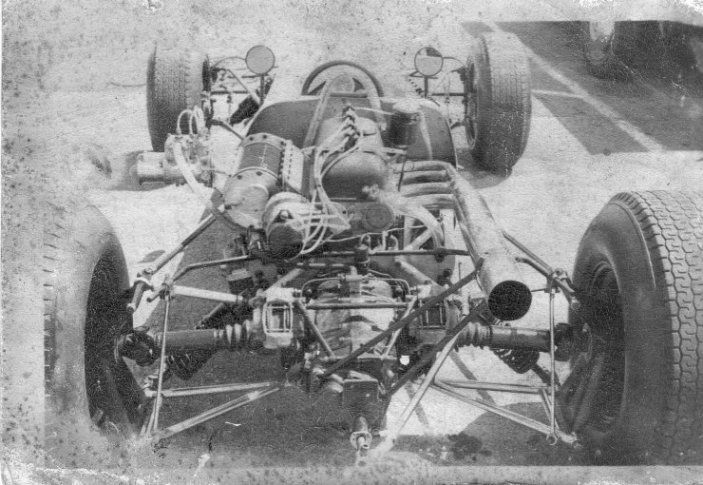

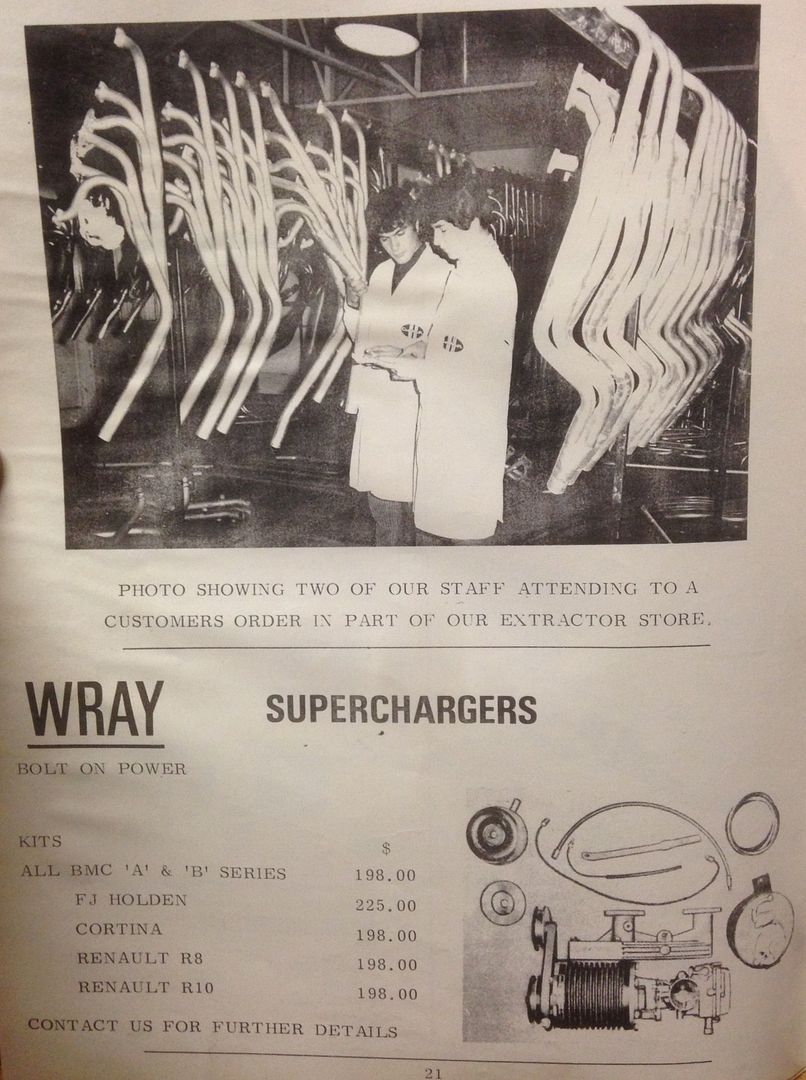

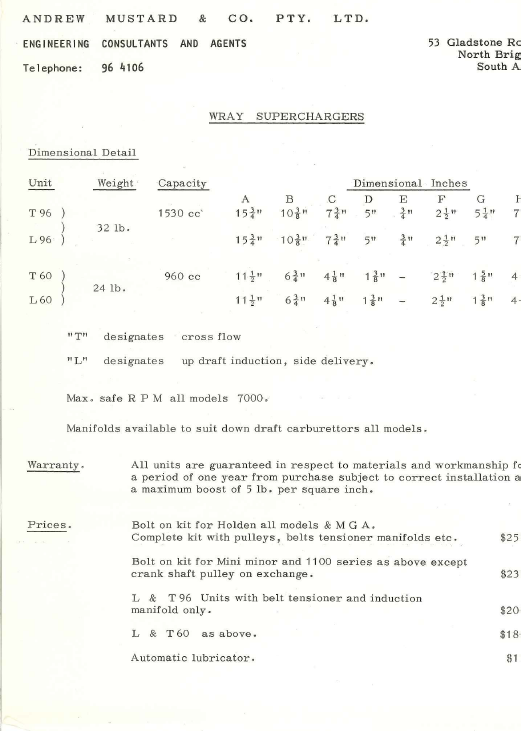

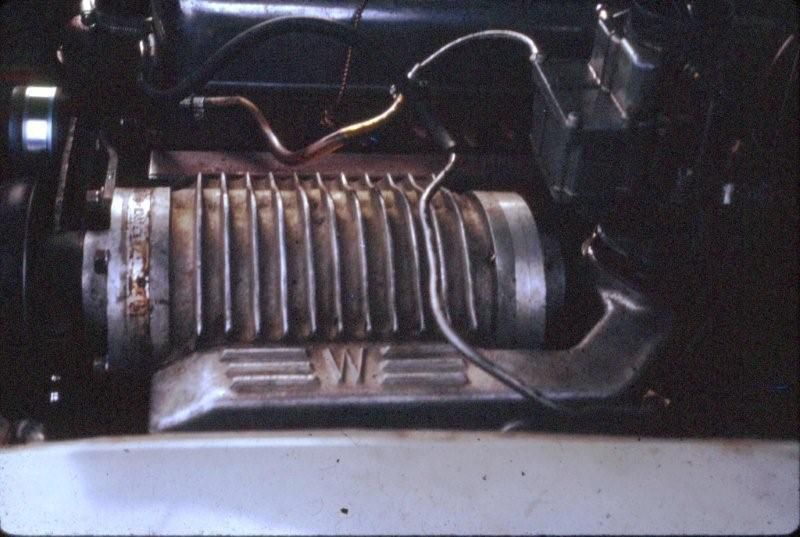

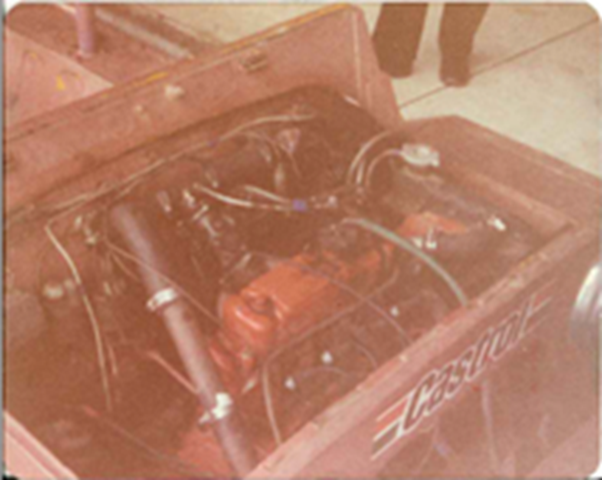

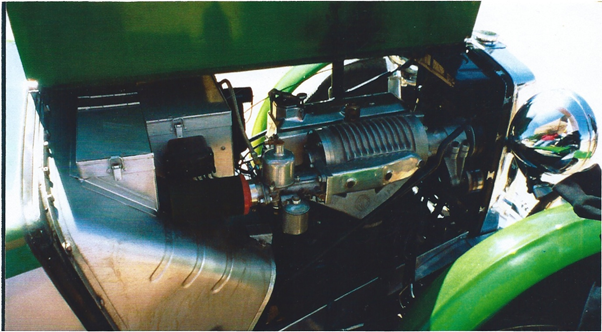

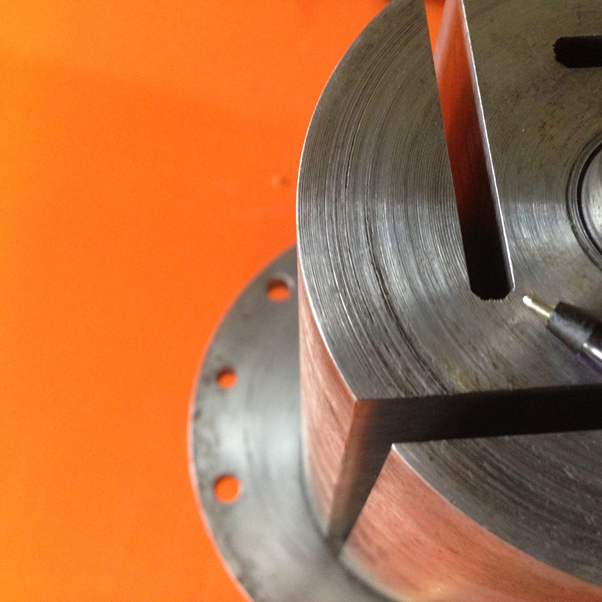

The photo below, which I have taken from the internet, shows a Wray fitted to an unknown 1990’s rotary vehicle using twin HIF7 SU’s. I suspect this is John Basset’s (from Southern Fuel Injection, and linked to Globe Industries) RX3, which later was sold in Western Australia:

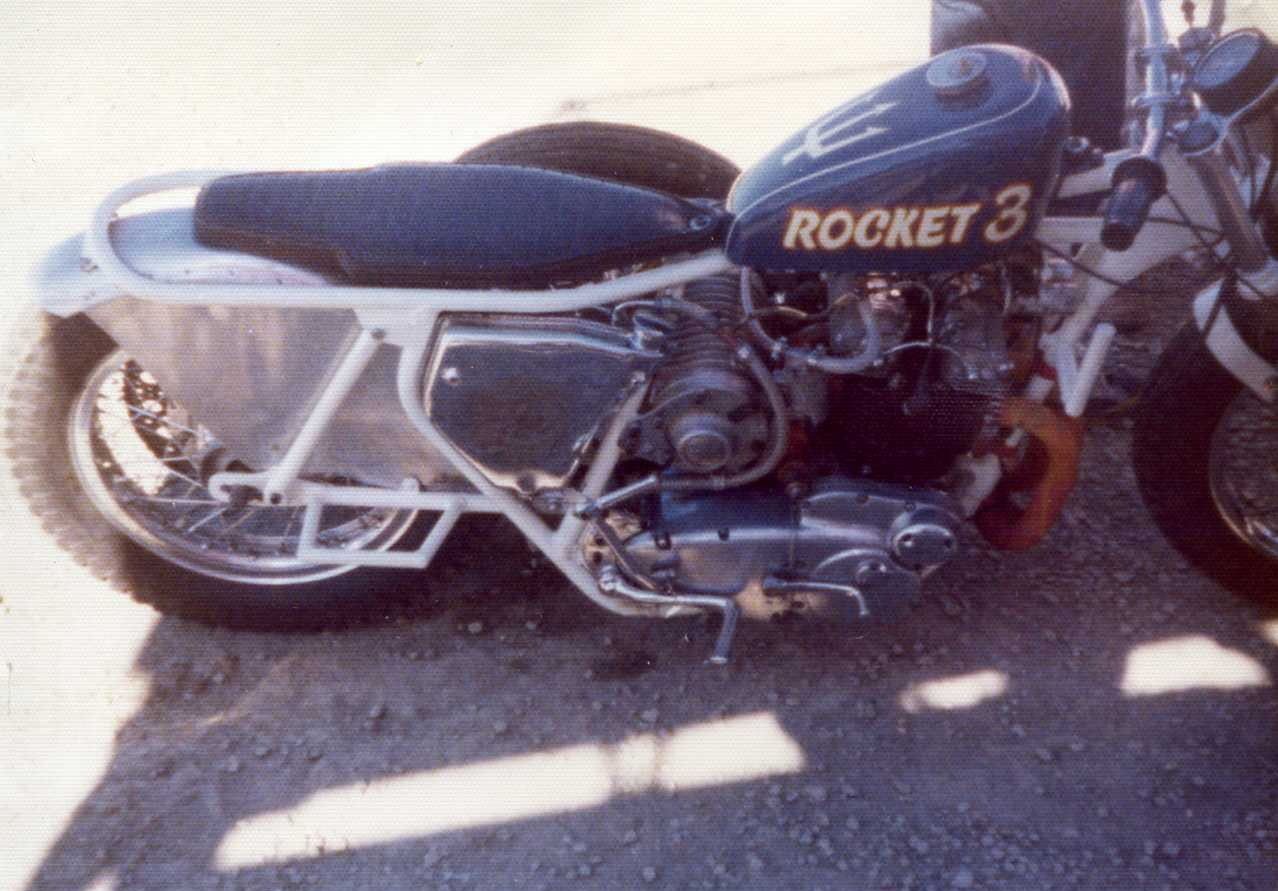

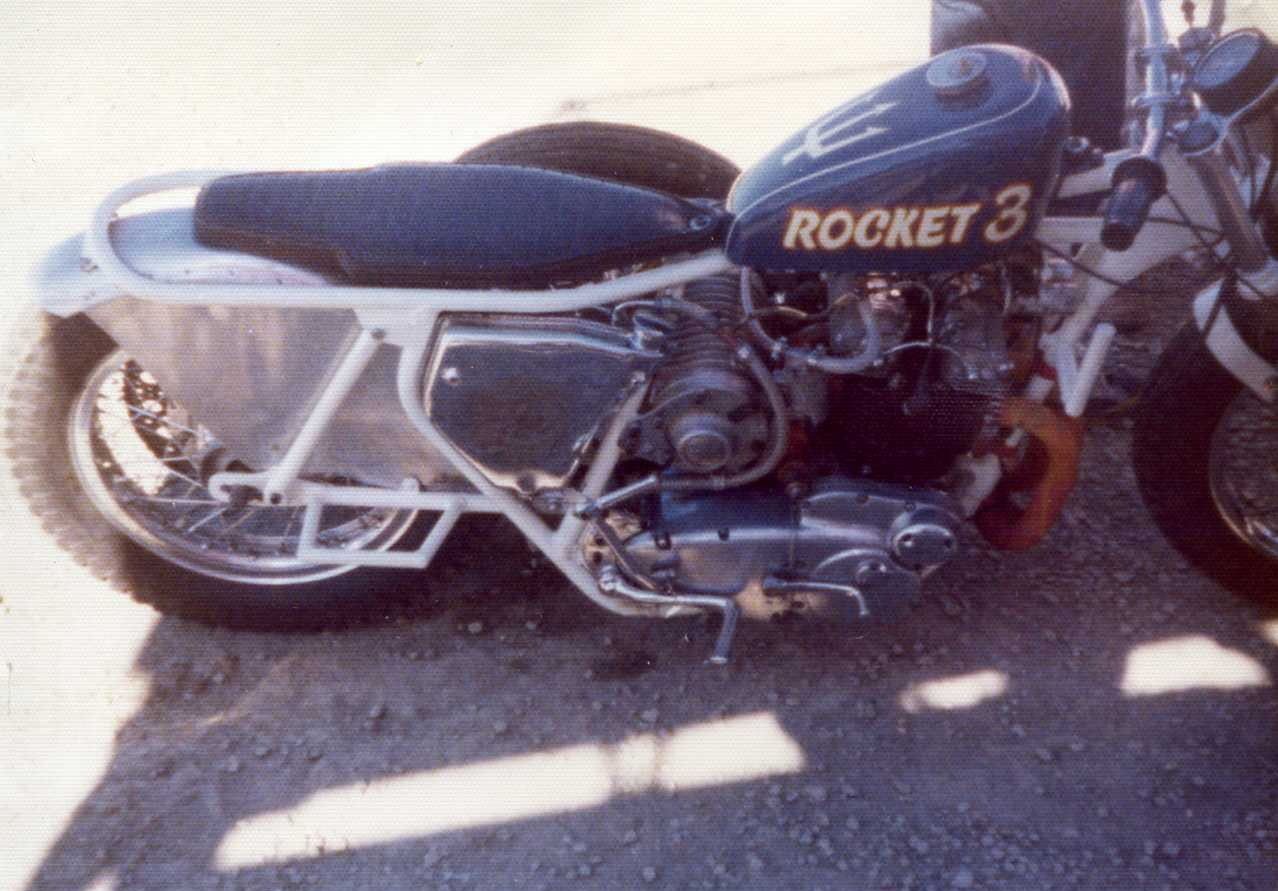

The smallest engines installations were fitted with Wray superchargers were two speedway motorcycles installed in 1976 for Bob Cronin. The first vehicle was a Birmingham Small Arms (BSA) Rocket 3, running on methanol. The BSA was Bob’s first venture into speedway racing - with no previous experience for him and his passenger on a ‘home made’ bike they were very competitive. The BSA Rocket 3 (a.k.a. Triumph Trident) was a three cylinder 750cc air-cooled pushrod overhead valve engine coupled to a dry plate clutch and four speed gearbox (some 200-odd were lucky enough to get a fifth gear). Over 27,000 Rocket 3/Tridents were produced during its seven-year history… though only Bob’s two would be Wray-blown . In the image below (photo: Greg Pill), the Wray T96 supercharger can be seen nestled below where the fuel tank and seat join.

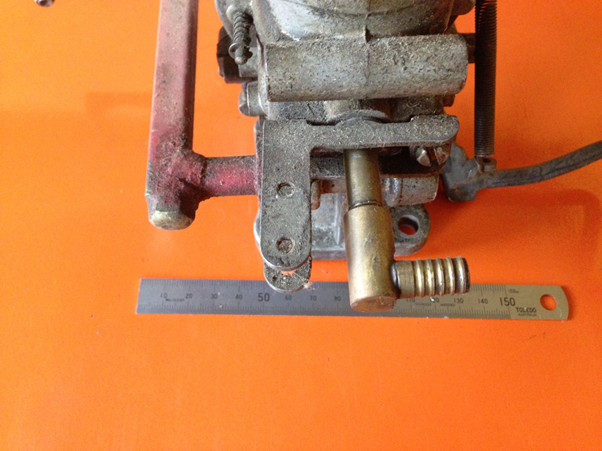

Bob’s second outing into home-made crotch rockets was powered by a sleeved-down 750cc Volkswagen engine. Bobs theory was that if the test engine worked in competitive service then a stronger, better engine would be built using after-market crankshaft, crankcase and heads. Initial engine was a 1200cc (40hp) crankcase, modified 40hp heads, custom cylinders utilizing 750cc Suzuki water-bottle pistons giving a capacity of 750cc. The Wray T96 supercharger was installed and can be seen in the image below (photo: Greg Pill), nestled below the fuel tank.

The bike had a very low centre of gravity, light weight and high power. Both of Cronin’s Wray-blown speedway outfits were tested and raced at the Rowley Park Speedway in Adelaide. They were very successful due to impressive power outputs. Unfortunately they were too successful; culminating in 'blown motors' being banned.

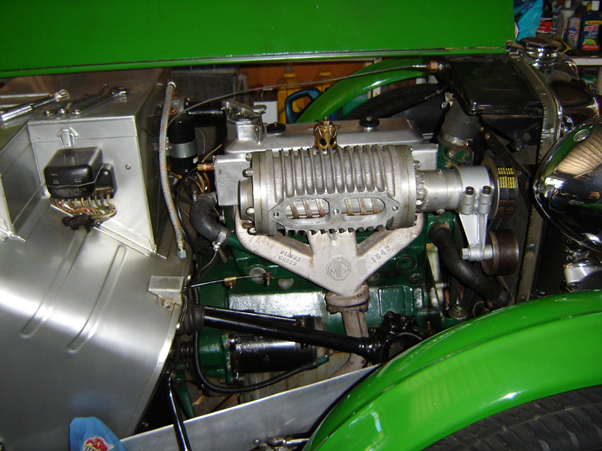

The Western Australian MG fraternity, recipients of the last batch of Wray superchargers, remain strong users of the machinery. Kevin McMahon runs a small Wray on his MG TC & Y Special (shown below in Kevin’s photo, followed by an image I lifted from the internet), as has Peter Compton, Rob Bodkin, John Bowles and Ed Farrar.

The Wray on Kevin’s Special was reworked by John Bowles, who machined the nose so that the bearings could accommodate the front engine attachment. Ed Farrar machined the vanes. The Special runs around 7½psi boost, indicated by a Spitfire (aeroplane) boost gauge. The video below shows Kevin’s vehicle at the 2015 Northam Flying 50:

https://www.youtube.com/watch?v=NKT8oyDycEE

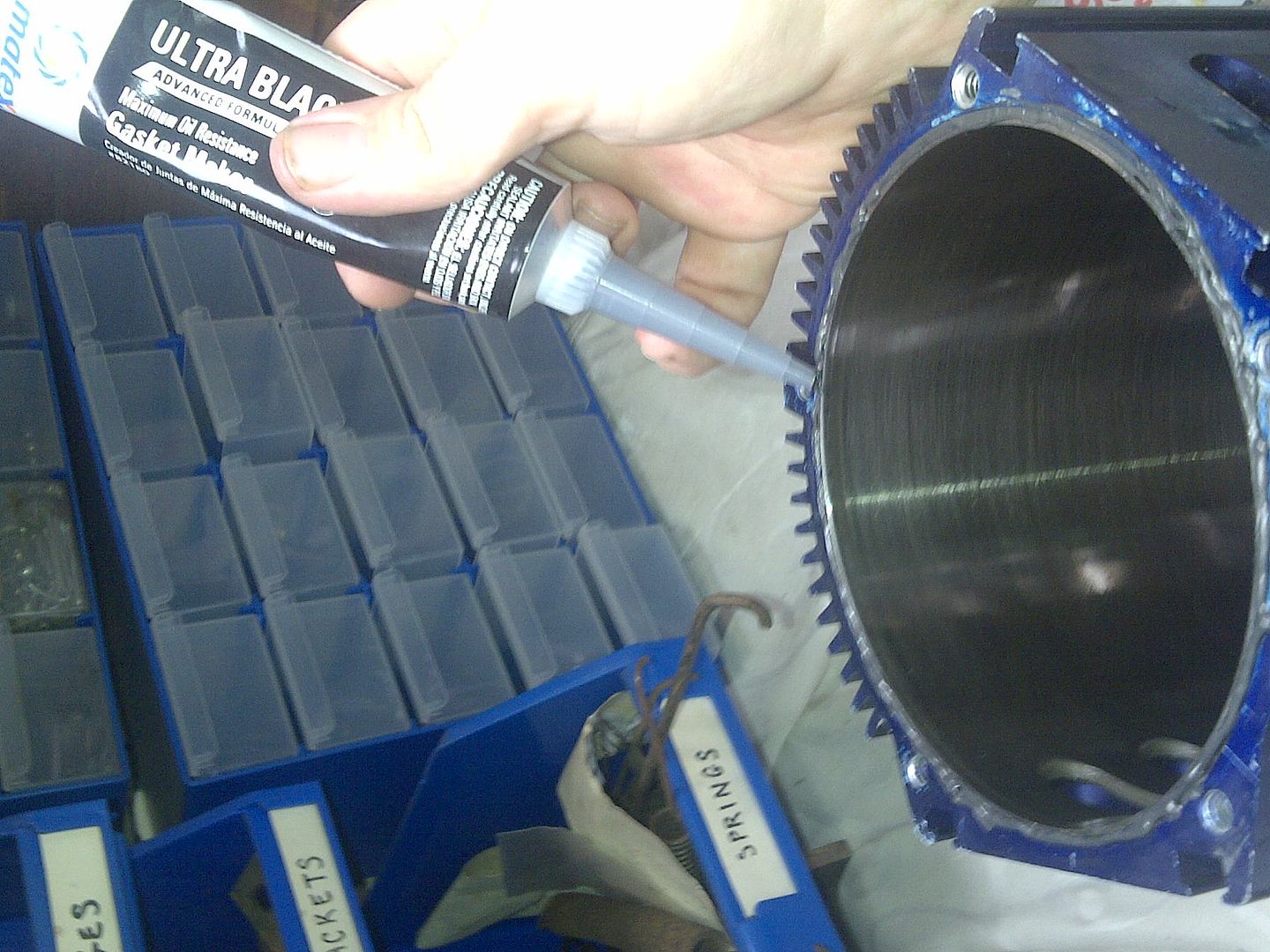

The Special sees active race service, having beat both a Morgan and a Mazda MX5 at Barbagallo Raceway prior to blowing the gasket between the supercharger and inlet manifold.

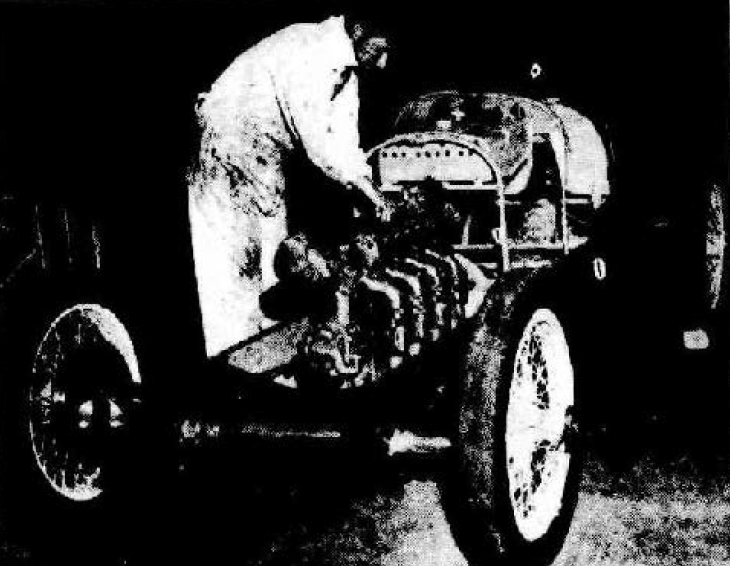

Don Tosler (Toesler?), from the Rostrevor area of Adelaide built a mid-engined (Wray-blown 16TS) Renault 750 as a sports sedan hill climber. Mid-build, CAMS changed the rules, banning mid-engined cars and forcing Don to campaign the car under a different class, competing at circuits that included Collingrove.

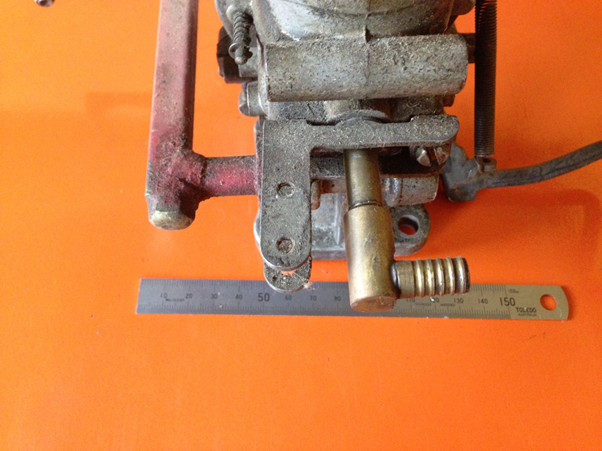

Don Fraser from Revmaster Engineering Camshafts (Sheldon Street, Norwood) was a 1960s boat racer who had an Amilcar with a Wray-blown 2242cc Whippet motor. Amilcars were made in France between 1922 and 1938, whilst Whippets were made by Overland (Willys) in the US from 1926-1931. Don built the Amilcar in 1975. Pictured below (photos: Fred Radman) is the modified HS8 S.U. carburettor from the Amilcar. This used a Lord mount to hang the float bowl. The 3/16” jet is home-made… and somewhat larger than the factory 0.125”. The needle is stainless steel.

Don removed the carburettor along with the supercharger prior to sale as he was using it on his new set up. The Wray was subsequently replaced with a Roots supercharger with twin SU carburettors. The vehicle passed from Don’s hands to Neil Sullivan in 1999. The photos below show the Amilcar in it’s Roots-blown format:

Pictured below (photo: Dave Linton) is Dave Linton’s 1275cc Wray-blown Moke. In the late 1980’s Fred Radman offered Dave a Wray L60 BMC “A” series supercharger kit to install into the Moke. A fresh motor was built, overbored to 0.020” resulting in 1293cc and a compression ratio of 9.75:1. A custom camshaft was re-ground via Chris Milton using the Special Tuning 731 timing. However the lobe centre angle was reduced to 100º. The additional overlap enabled combustion chamber exhaust gas purging with the incoming compressed air/fuel mix. The Moke firewall was modified to allow the drive belt to run directly to the bottom pulley (see the modified red lead painted piece of box chassis section in the photo below). This placed the belt tensioner on the correct side (slack side) of the belt. The alternative (without the box section) places the tensioner on the drive side of the belt. A standard Moke harmonic balancer had a second vee groove cut into it to provide drive for the supercharger. After experimenting with a downdraught D5 S.U. carburettor and a Reece Fish, the carburettor was changed to a downdraught Stromberg as used in a Holden 186 red motor. A variable main metering jet was installed on the carburettor to adjust the fuel mixture. The Moke used a Marvel inverse oiler on the far side of the engine bay (complete with synthetic two-stroke oil). At full noise, the setup generated some 8–9psi of boost. Dave used the Moke daily for six months of the year over a couple of years, as Adelaide has pleasant weather from October to March. The main issue Dave experienced was that of carburettor icing during prolonged light throttle with cold ambient air temperature. Soon after installation the rotor failed, though cutting the fan belt enabled the Moke to be driven home to be repaired. Once the rotor had been replaced there were no other issues with the supercharger. The Moke competed at the Collingrove hillclimb and street drags at AIR. (Adelaide International Raceway). It was driven to the Australian Motorkhana Hay Nationals at Hay, NSW, with the Moke double-entered for two drivers. This is a round trip of some 1300km, with the carburettor icing issue being the only problem experienced on route.

Note the Wray sticker on the air cleaner. Fred had some of these made up in later years (photo: Fred Radman):

The photo below again from Dave Linton shows a T96 on a 1275cc Mini motor. The Wray manifolding has a Shorrock blow off valve which was found to seal better than the earlier plate type. Note that the manifold casting has been cut back to allow for a sidedraught carburettor.

More photos from Dave below:

Lachlan Kinnear has a Wray on a vintage Vauxhall, whilst John Payne has a Wray on a MG Type 2. Lachlan’s Wray has the earlier cast rotor, and was earlier fitted to a Holden red motor from Mannum, South Australia. Lachlan also has the original Wray belt tensioner arm and inlet manifold.

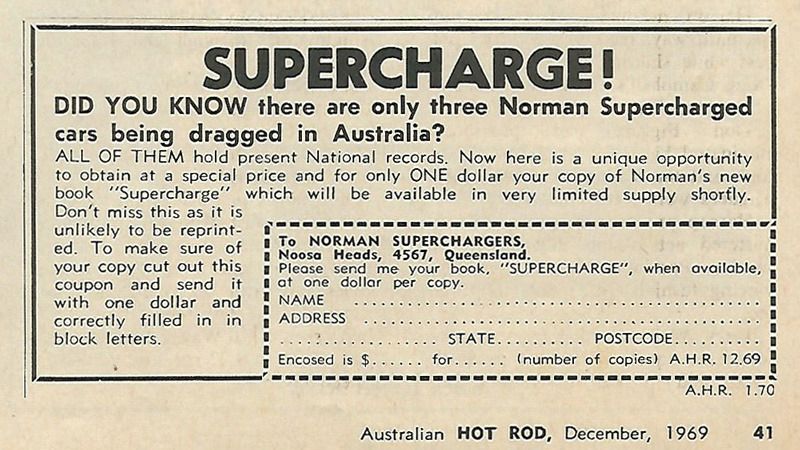

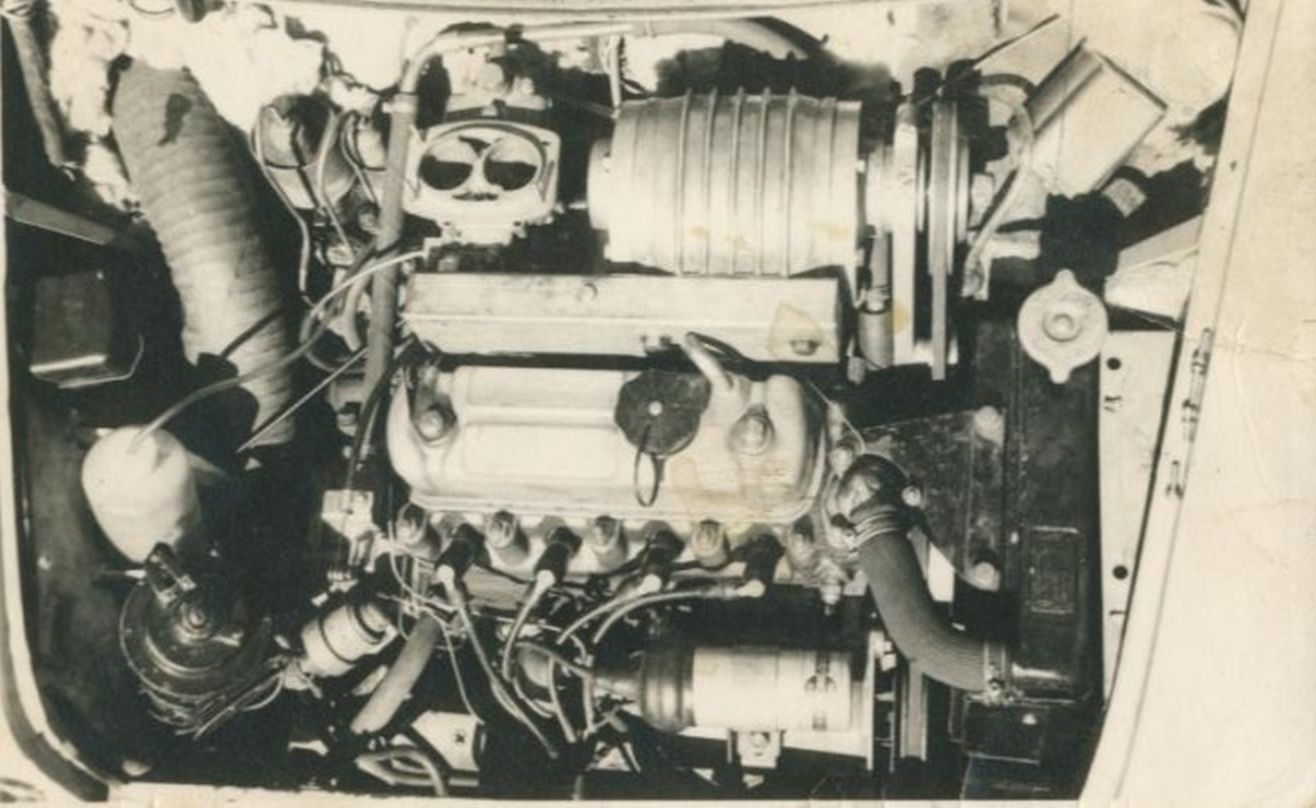

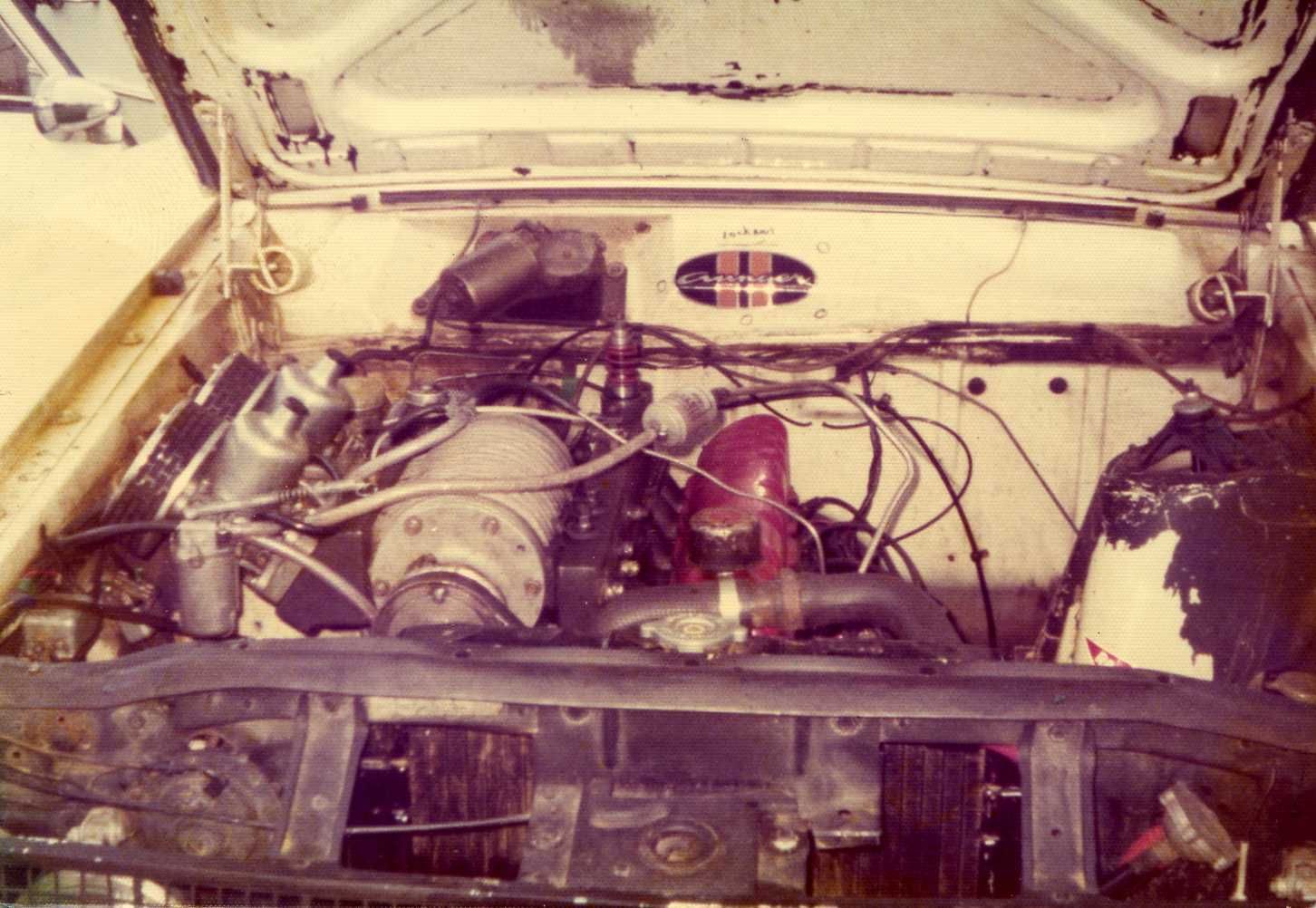

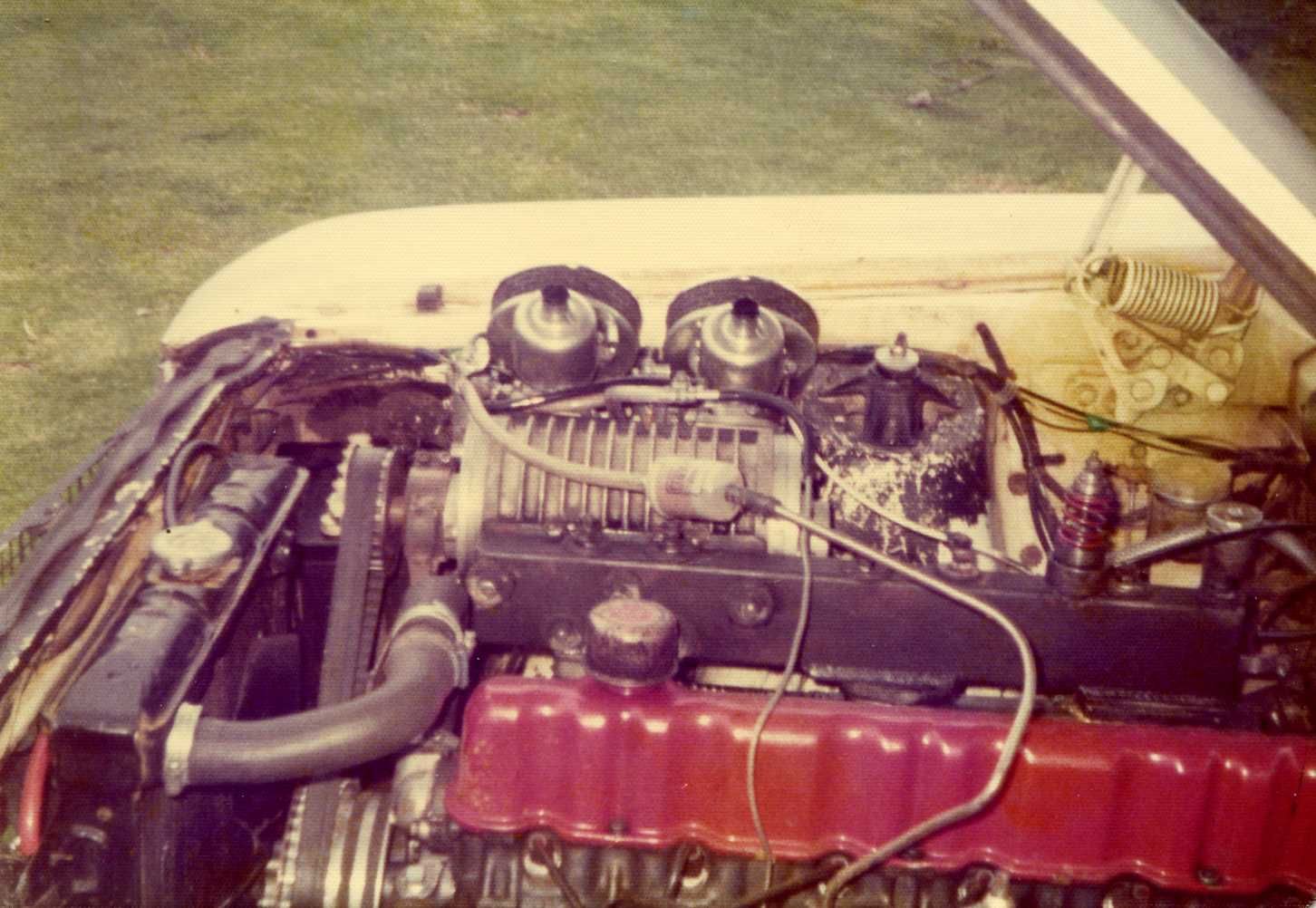

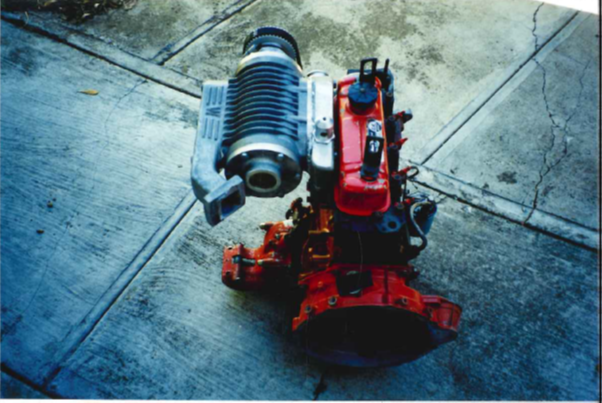

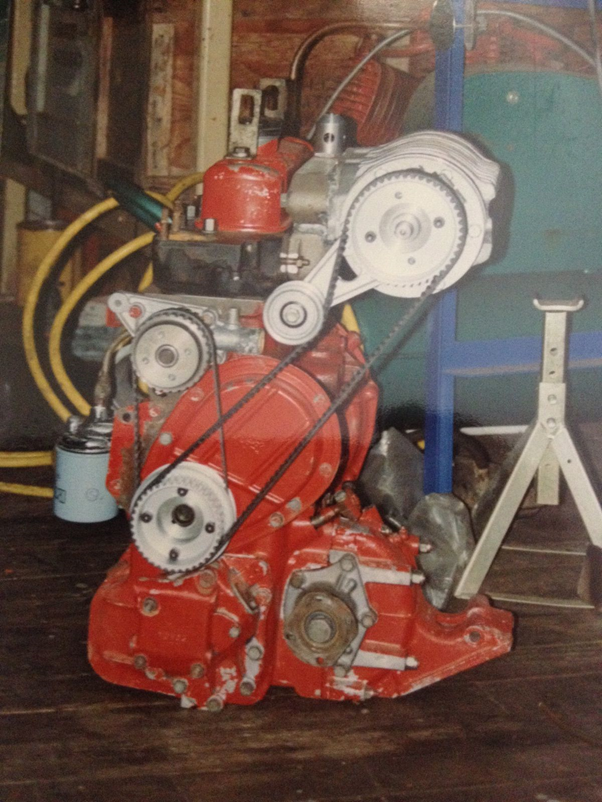

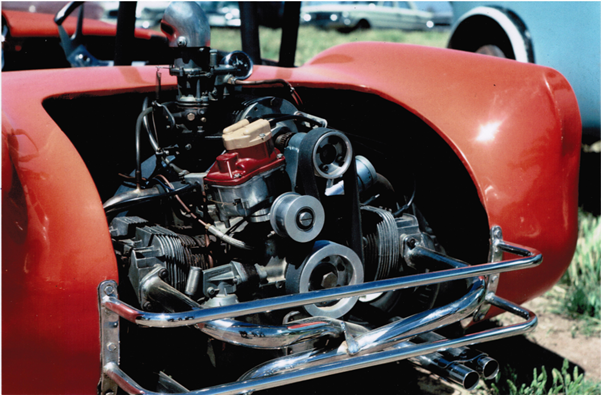

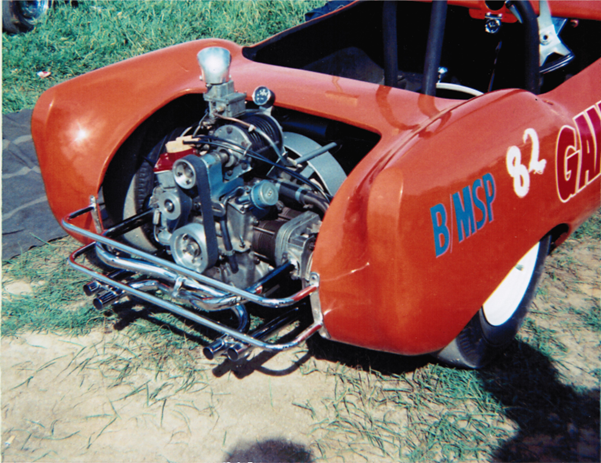

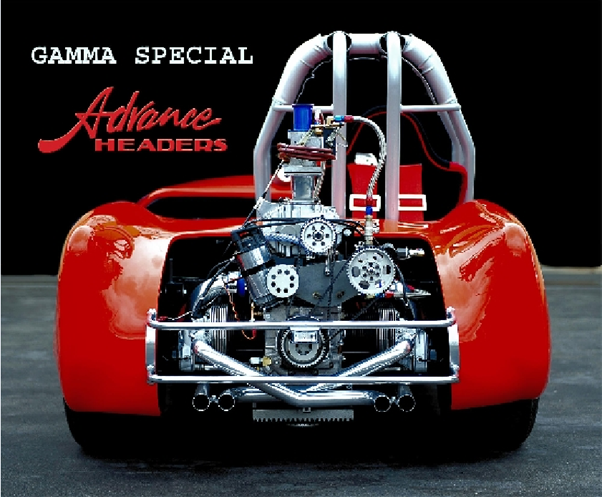

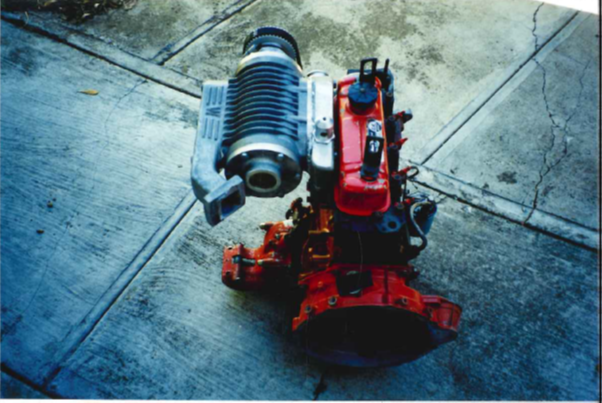

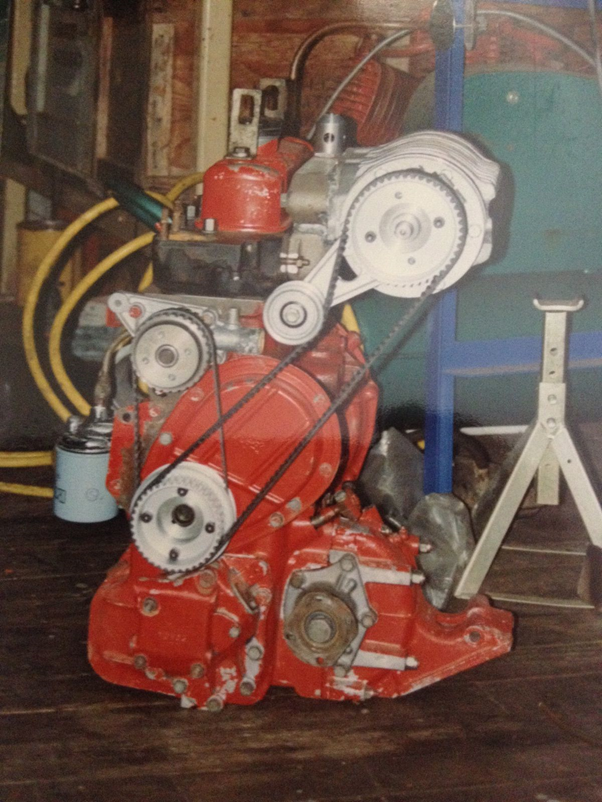

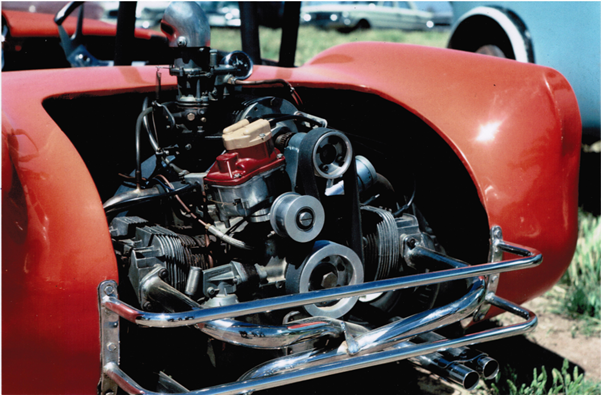

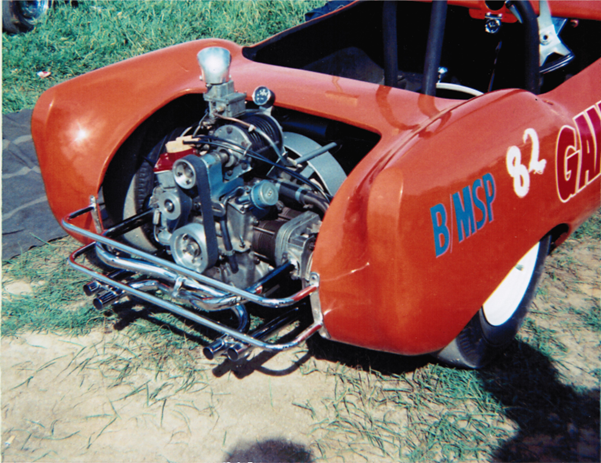

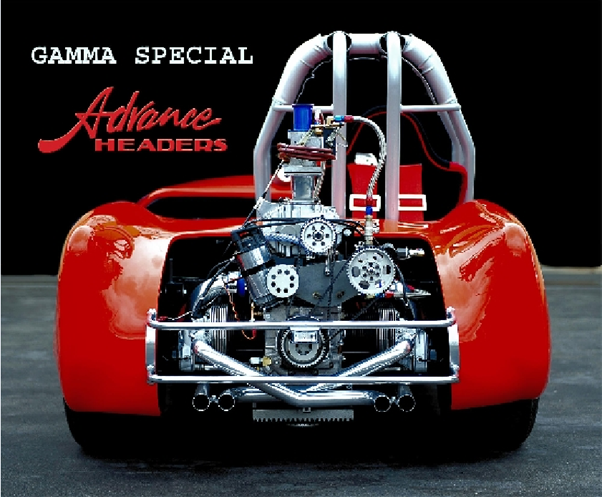

Mike Adi’s (Advance Headers 16 Braeside Avenue Holden Hill South Australia 5088) Gamma Special Goggomobil was initially configured as a Wray-blown VW engine. The vehicle then moved to a Norman, and later to a Toyota (Aisin) SC14 running around 20psi of boost. The Wray was later sold to Brian Paige who fit it to a Simca. The photos below are from Mike:

The Aisin-blown vehicle is shown below at Whyalla drags (I have lifted the images and video from the internet):

https://www.youtube.com/watch?v=vff3f9X4Ik4

https://www.youtube.com/watch?v=9hzBd4qzrLo

https://www.youtube.com/watch?v=vff3f9X4Ik4

https://www.youtube.com/watch?v=9hzBd4qzrLo

… and finally, a photo from Mike of the rear of the car:

Rod O’Malley purchased a 1275cc MG Midget, and rebuilt the vehicle whilst still in his teens. The car was likely an ex race vehicle, notable through things like circles being painted on the doors (under layers of paint) and the sump plug being safety wired. As part of the rebuild, Rob acquired a small Wray supercharger in pieces. Having made his own manifolds to fit the Midget, the supercharger was reworked by Wray, with the casing rebored and the rotor slots tidied up before new vanes were fitted. The supercharger developed up to 5psi, though at any more loading the single vee-belt suffered slippage or breakage… Rod got around 500 miles from any given belt. Water/methanol injection was added to the Midget. The logbooked Midget would go on to serve as Rod’s road and track car, racing at circuits including Calder, Winton and Mallala. The car also saw service in motokahanas, though would only get 1½ events between gearbox failures. A 5.3:1 differential was later fitted for the Colingrove hillclimb, with the car starting in 2nd gear. Rod eventually sold the car through MG Sales (

http://mgsales.net.au/).

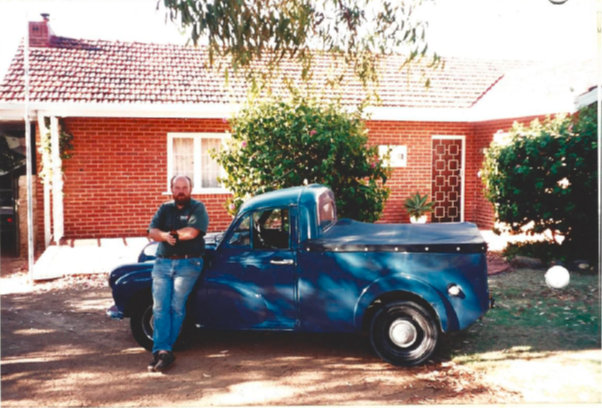

Ed Farrar has a Wray-blown Morris Minor ute, which has travelled some 400,000 miles in Ed’s ownership. The Wray supercharger kit was purchased through Don Hall Motors in Subiaco, Perth in the late 1970's or early 1980s. The Morrie originally had a relatively standard 948cc engine, with the Wray kit only taking a few hours to fit. The first test drive of the ute, with Ed’s father riding shotgun, showed the car to be very strong. After a lap around the block Ed pulled up in the nearest straight road… the local shopping centre. From a standing start, Ed warned his father that he would see what the Morrie would do wide open. Ed got wheel spin in first, which continued through second gear. By the time Ed found third gear he was doing twice the speed limit… an inopportune time to pass the local Policeman.

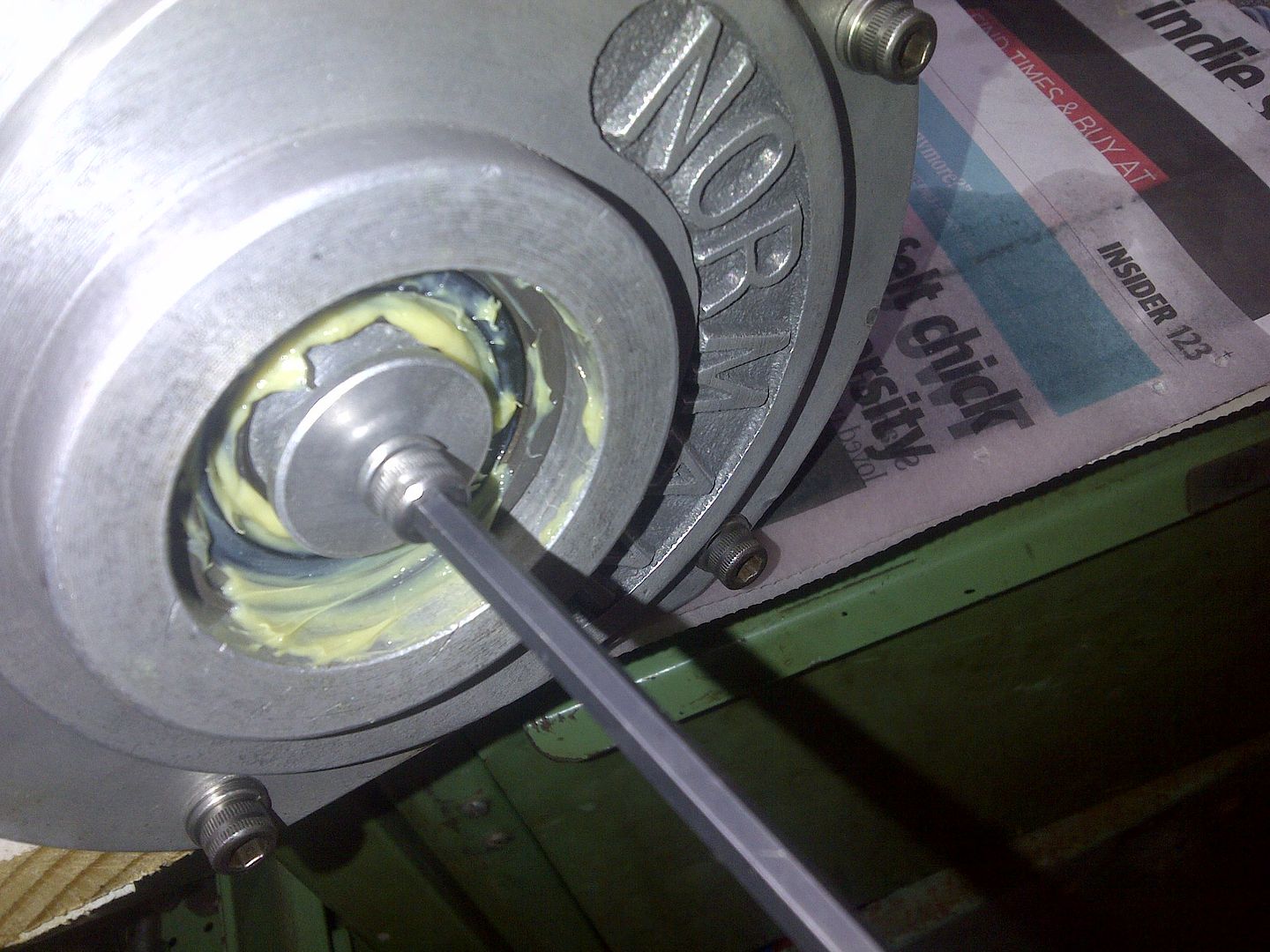

After some 100,000 miles of service Ed was tiring of the engine taking a hammering from the supercharger. He purchased a complete Morris 1100s for $200, pulled the 1100cc engine and cut the end from the crank. A piece of steel was welded to the crank end and then machined to fit the standard lightened four-bolt flywheel and a Mk1 MG Midget clutch with uprated springs. In the following 300,000 miles the Wray-blown 1100 motor would only see one rebuild and one re-ring. As one of Ed’s friends found out, it’s not a good idea to bet the ute won’t do 100mph… Ed won the wager on the way to Esperance, leaving his mates brand new Honda Accord smoking at the side of the road from having tried to keep up. The Morris has seen some good loads over it’s time, often doing diving/camping duties (driver, two passengers, diving cylinders and compressor, tent, outboard motor and fuel tank, and 10’ boat on the roof). The Morrie has a new set of vanes fitted every 20 to 30 thousand miles depending on service conditions with the rotor being given a tickle each time. Ed carries a spare set of vanes under the seat in case of emergency.

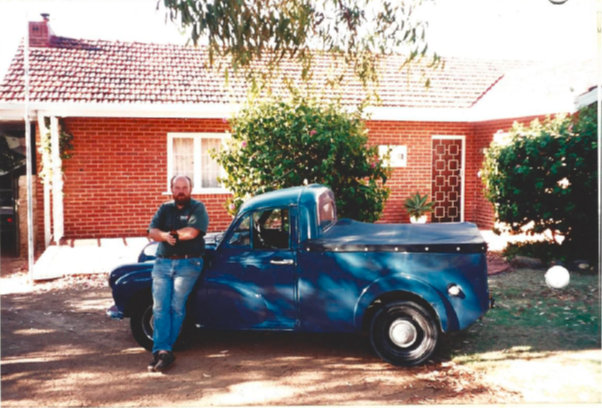

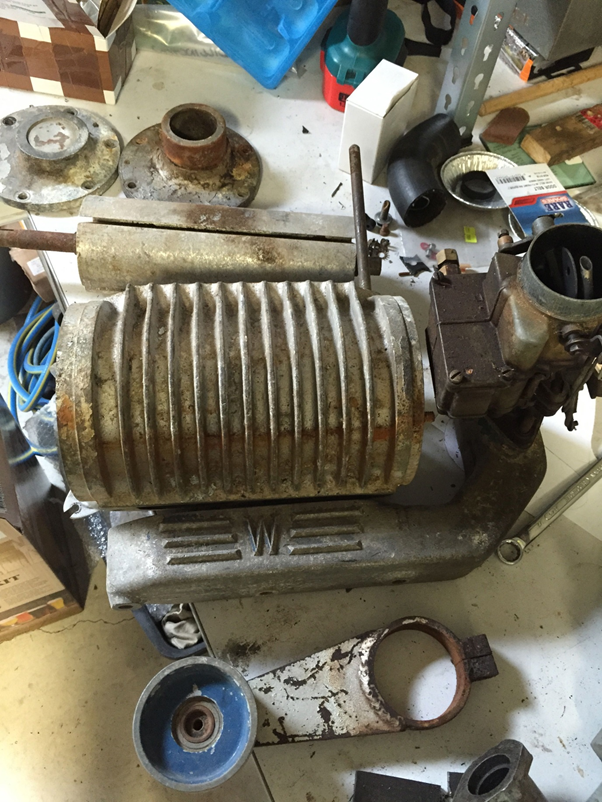

Images below of the Morrie are from Ed:

Ed has run his Wray’s hard over the years. While competing in a motorkhana at Mooliabeenee (north of Perth, Western Australia), he ran the Wray without an air filter. The gravel turned a freshly rebuilt supercharger to scrap in a single day.

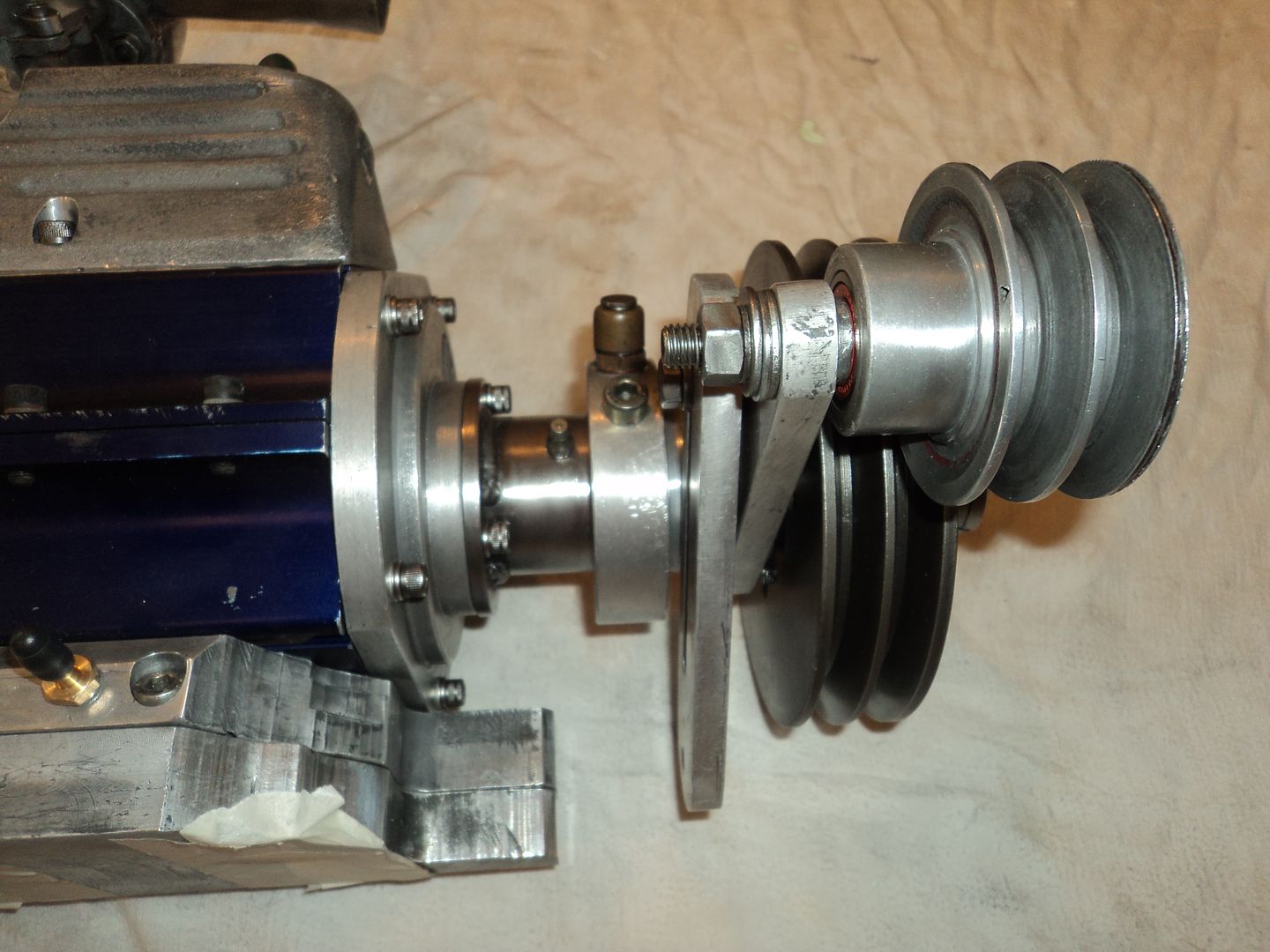

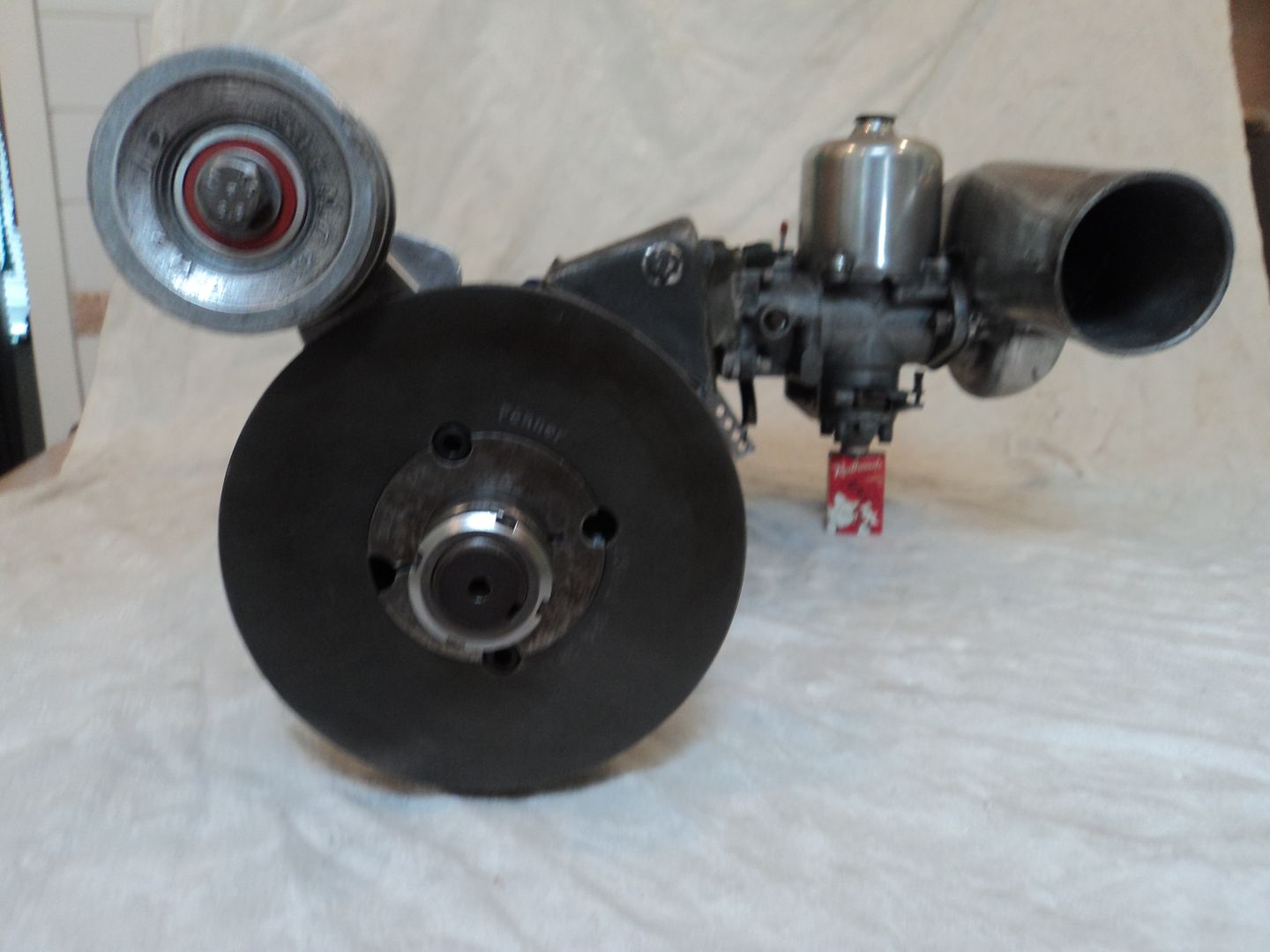

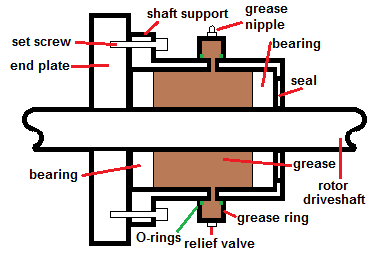

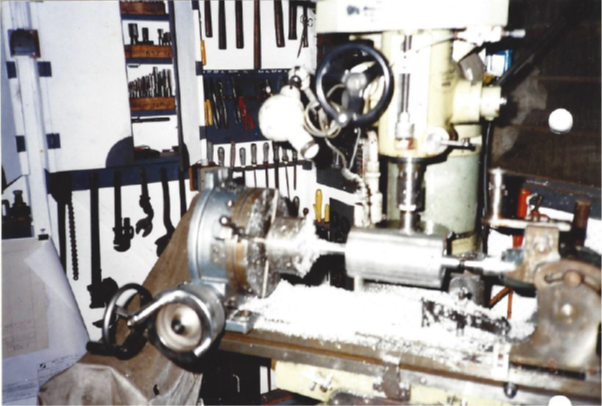

Ed has also made a number of spare rotors over the years. Ed targets a drive-end rotor-to-casing clearance of 0.002”-0.004” (Norman superchargers can be set to similar tolerances, though 0.010” is typical), and a non-drive end clearance of 0.018”-0.020” (Normans are typically 0.015”, with the early Type 65’s able to be set to 0.006”-0.008”). Ed has seen some Wray superchargers with as much as 0.080” clearance.

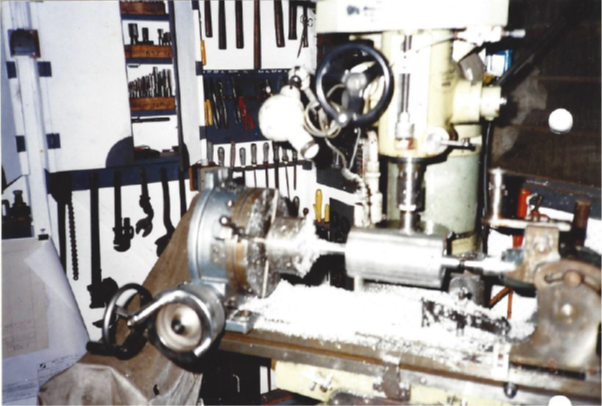

The photo below from Ed shows a rotor being machined:

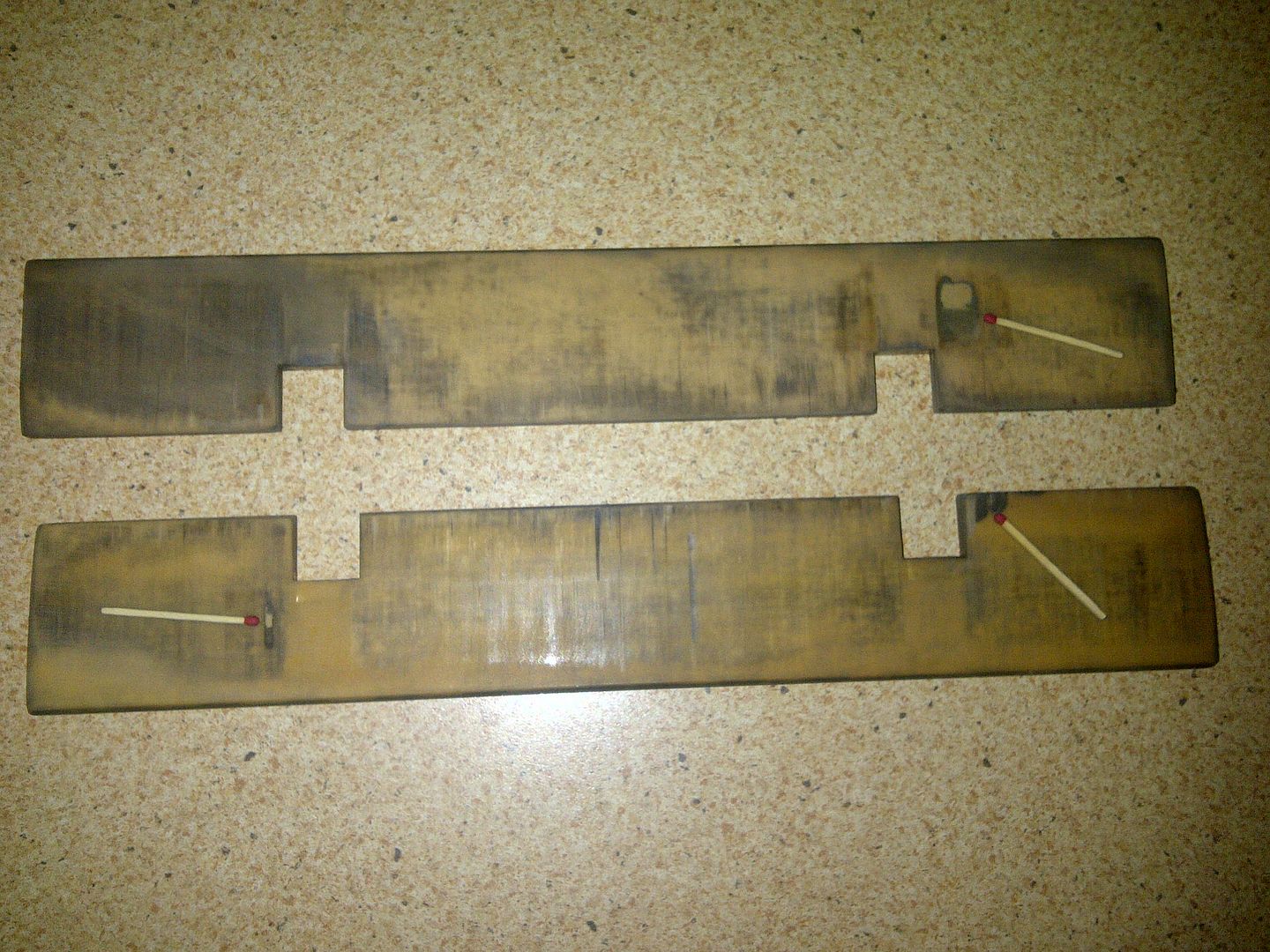

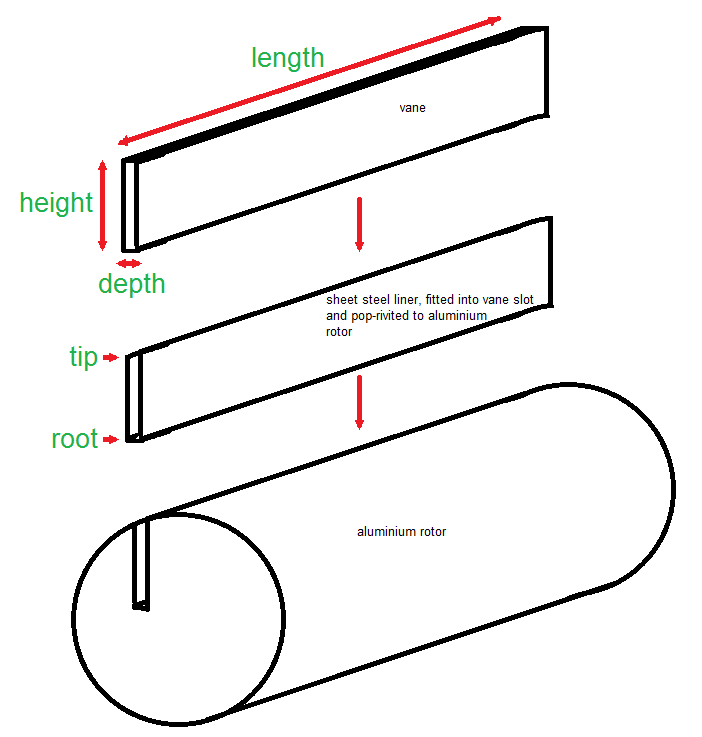

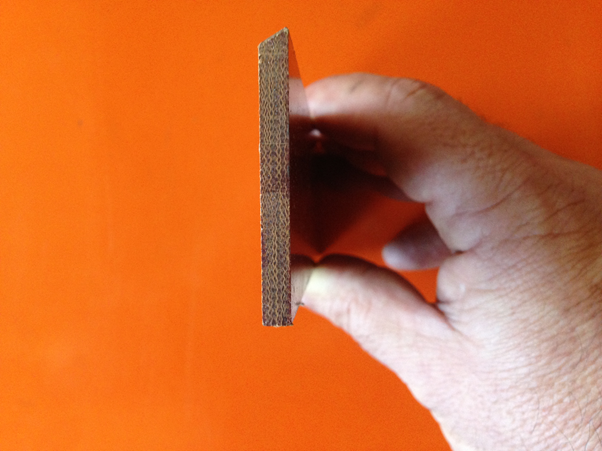

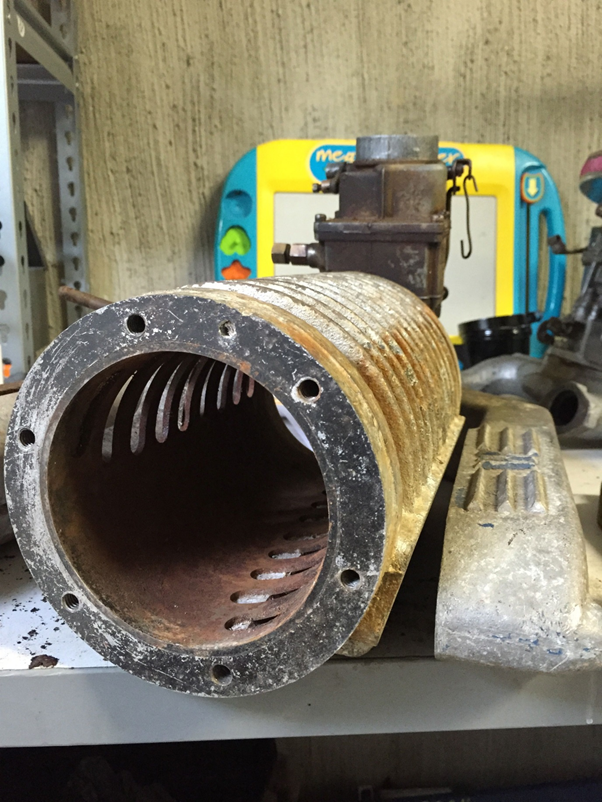

Ed and the WA MG crowd have also continued the development and upkeep of the Wray vanes. Harry Pyle has sourced vane material. At some time in the last ten years the vane material became a problem, probably because the thickness had been rounded to millimetres. Chris Foreman of Armstrong Energy (181A Star Street Carlisle, Western Australia, telephone (08) 93612761) is able to supply the thicker vanes but can also machine them to fit the rotor. He is also cutting diagonal grooves designed by Ed Farrar to help seat the vanes against the casing. Ed originally found the concept for the grooves in an American publication on sports car modification. The grooves are shown in the image below:

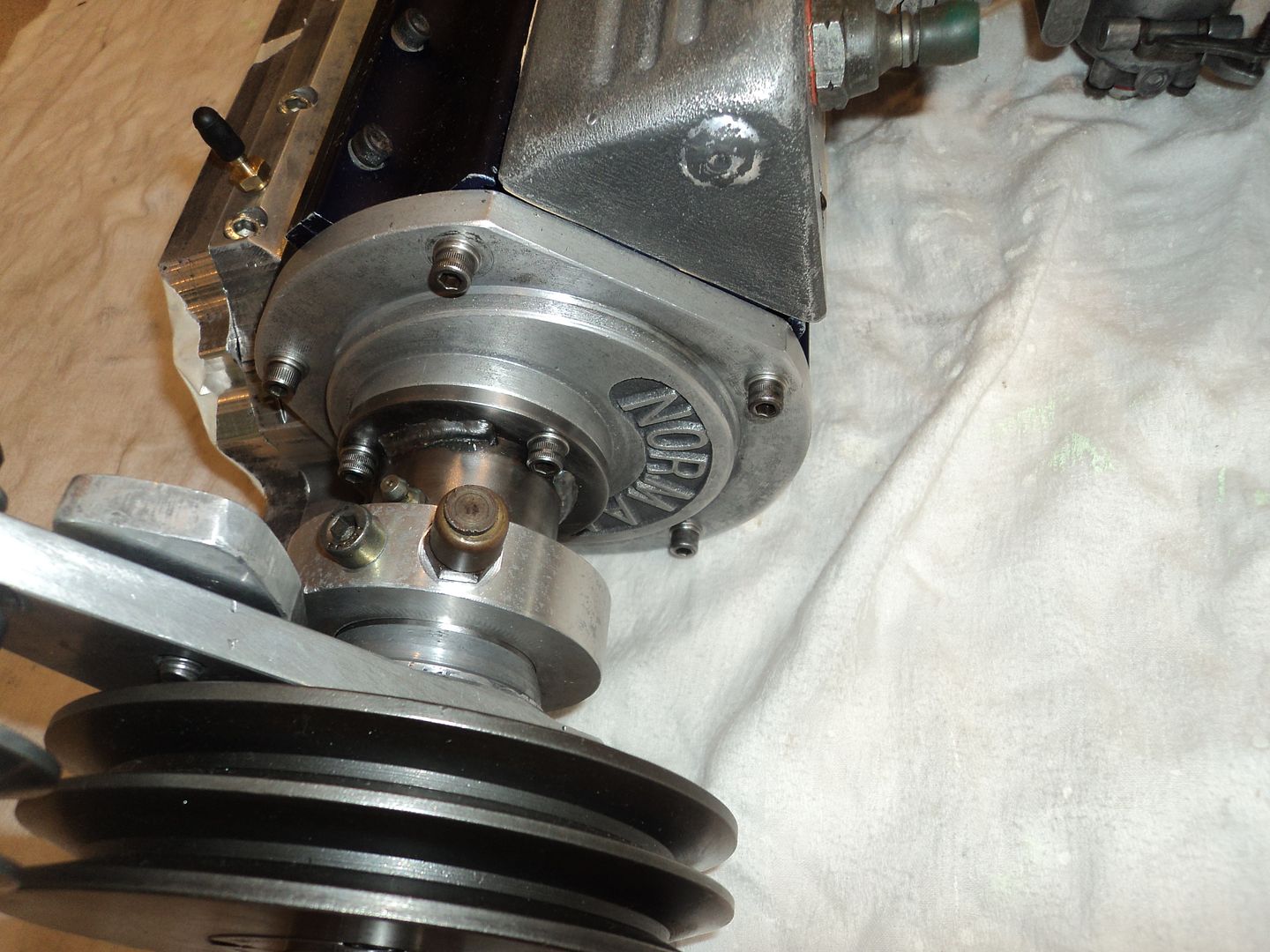

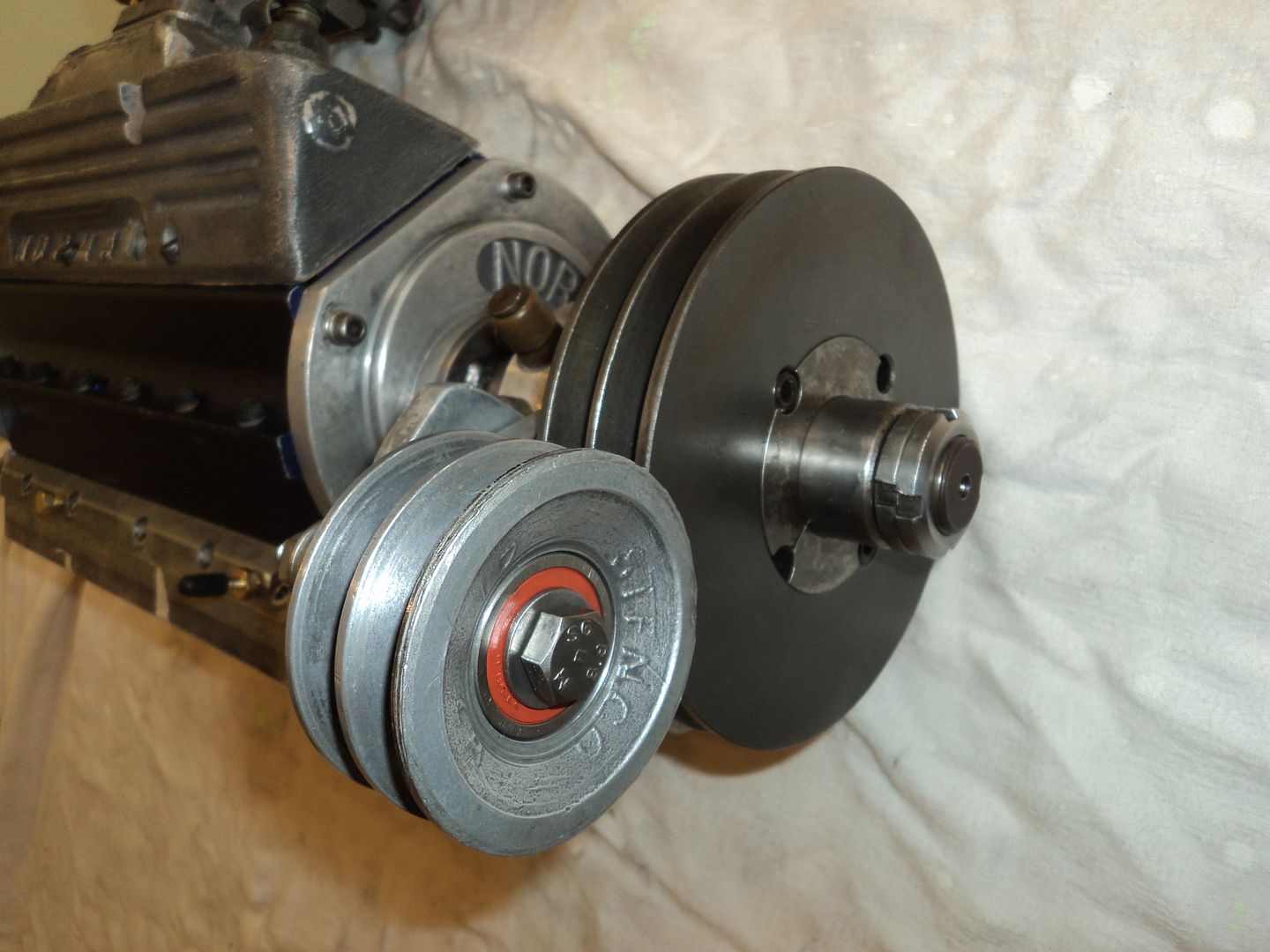

Note that this is similar to the grooves used in the Norman superchargers produced by Mike Norman (see image below). Eldred’s machines did not use grooves.

The Farrar-modified Wray grooves are cut to one third of the vane thickness. The grooves are used to assist the vanes in being able to move in and out of the rotor. Sliding supercharger vanes are normally a “flop” fit, though may experience some changes in dimensions due to moisture, fuel properties or dirt. If the vanes become a tight fit, the oily environment they operate in may allow them to form a seal with the rotor. In this case, the vanes will draw a vacuum at the vane root as they try to slide out, or will build pressure at the vane root as they slide back in. The grooves allow the vane root to equalize pressure, allowing the vanes to slide freely. The slots also allow some flow of air/fuel/oil around the vane, helping lubrication. The Farrar-modified Wray grooves are sufficient to eliminate vane rattle at idle. At idle speed the centripetal force on the vane is low, and they can lose contact with the casing wall, giving a rattling sound. For the (Mike) Norman superchargers, the grooves are not sufficient to stop vane rattle, and springs are fitted under the vane (the square notches in the yellow vane show above are used to seat the springs). The Farrar-modified Wray grooves are angled, helping to sweep out any debris arising from vane wear.

Ed also has a complete spare Wray supercharger, and rebuilds Zoller sliding vane superchargers. Arnold Zoller (1882-1934) was Swiss machine technician, and worked for Fiat for several years designing racing engines before co-founding a business marketing the Nazzaro car. From 1917 he worked for Argus Motoren, focussing on developing the supercharger, particularly for two-stroke engines. This lead to the invention of the Zoller sliding vane supercharger in 1927, which were used in vehicles including BMW, DKW and NSU.

Another Wray-blown Morris Minor was owned by Phil Evans from the Morris Minor Centre, Adelaide. His ute ran a standard 948cc motor with extractors and the supercharger, and was used as the regular pick-up and delivery vehicle for the business.

The photos below, from the owner, show Tim Billington’s T96 Wray. This machine was purchased by Tim from a Mr Booth of Cooroy, Queensland around two years ago. It is an early Wray, with the early Mark 1 type porting. The manifold face that can be seen with a looooong stud hanging out of one hole was later modified by Wray to have four smaller bolts in addition to the three shown on Tim’s. Tim’s fabricated tensioner is not a factory (cast) Wray unit. On the periphery of both the casing a hole is noticeable at about the one o’clock position. This hole is used to install a locating dowel, that ensures the end-plates are rotated correctly with respect to the casing’s inlet and outlet ports. The end plates have a similar hole, along with another 180º around the periphery. The original Wray tooling has provision for drilling these holes (we’ll hear more about the tooling later), though not all Wrays had the dowels drilled. The carburettor-to-supercharger manifold (complete with grey motor BXOV-1 Stromberg carburettor) was cast before the pattern was altered to allow for both downdraught and sidedraught carburettors - the sidedraught carburettor boss is absent, and the speed stripes and “W” is as cast, not machined down as per the later Wray manifolds. Tim’s machine is destined for a Holden grey motor.

Gary Crosswell’s FC sedan is Wray-blown with an L96 (serial number L96/105), running on the over-bored (149ci) Holden grey motor. In lieu of the normal Stromberg, Gary’s Wray is fed by one of Eldred Norman’s massive 3” SUs.

Video of Gary’s machine is here:

https://www.youtube.com/watch?v=0x9rSqMfkKk

5. The Last Wrays

The last production of the Wray supercharger was an order in 1983, consisting of a mix of twelve superchargers (eleven small and one large model) for the MG TC Owners Club in Perth. These were to be installed on 1250cc MG TC and TD's, with the larger supercharger for 1588cc-1622cc MGA's. Interest in the order was sparked by Ed Farrar, with the order placed by Harry Pyle. Darryl Robins and Harry attended the MG Nationals meeting in Geelong in their MGTC’s. On the return trip to Perth they called into Wray Engineering and collected the batch of superchargers. Darryl had no passenger on the trip back and was able to carry most of the superchargers on the floor of his car, whilst Harry had two behind his seat. Harry would later note that in trying to fit one of the superchargers to an MGTC, a very large hole is required in the louvered bonnet side. Harry’s son Philip engineered a clever modification, turning the supercharger so that the inlet becomes the outlet and rephasing the end plates so compression happens between the inlet port and manifold port. This also entails drilling additional holes in the end plates – see photo below

Harry would go on to run the Wray-blown MGTC for six years as everyday transport. It is suspected that the supercharger is currently running on Kevin McMahon’s MG TC & Y Special, which we saw above. Harry was told in Adelaide that the patterns for the large supercharger would be destroyed, and that his was the last of the line. Thankfully, the moulds survived, and would lead to a later generation of superchargers… more on that below. Harry’s large Wray passed on to his son Philip, then to Colin Bonney unused, then onto Mike Sherrell. John Bowles assisted Mike by designing and building brackets and a manifold to finally fit the large Wray on to Mike's MGTC Special. The supercharger and kit were later onsold to Canada (more on this below). Philip Pyle fitted his small Wray in about 1984 to his Morris Minor convertible. Some years later Peter Compton fitted his small Wray to his MGTC. Pete Harper purchased a Wray supercharger some years ago from a Mr Muir, along with the pulley/speed scale paperwork. The machine is pictured below, running a Holley Model 1904 carburettor (the 1904 was common in Judson applications). The manifolding suits the BMC "A" series engine. The machine has never been installed or run. It is likely that this machine was part of the last batch of twelve.

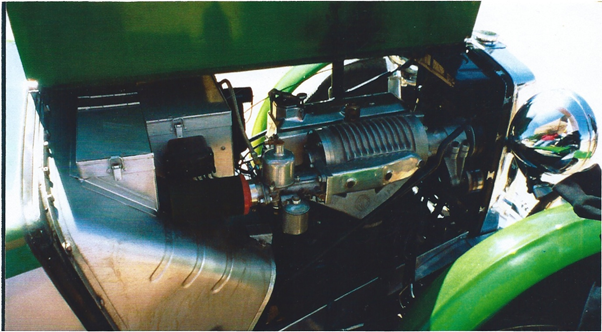

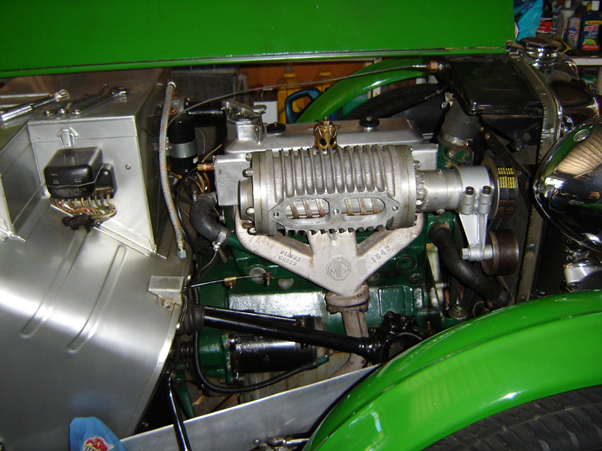

As noted above, Harry Pyle’s large Wray was sold on to Mike Sherrell. The supercharger was destined to be fitted to Mike’s 1949 1275cc MGTC/9349 XPAW motor. In July 1998 work began on a plenum chamber, with the supercharger being fitted over the next few months. The Wray-blown MGTC was fitted with an 1¾” S.U. carburettor, running a 0.125” jet and UVF needle. It’s first outing was at the Joondalup Round the Houses meeting in October 1998, and was nothing short of spectacular. Boost was off the dial, with the MG rocketing away from the other racers at the start, only to fuel up and bang the relief valve. The mob would then swarm past the MGTC, wreathed in clouds of black smoke. The XPAW would then clear its throat and roar away after them. With enormous torque it would rocket out of the course's tight corners and soon be up and through the pack, only to have the whole process repeat itself over and over. It may have taken some time to get the grin off Mike’s face after the race. The MGTC was in for some serious tuning before it’s next outing. A larger drive pulley was fitted, reducing supercharger speed to 85.7% of engine speed. This reduced boost to a more sane level (if 12-14psi can be called sane). The relief valve spring was reset to around 16psi, whilst the SU needle was leaned up to UVA. The distributor advance was retarded severely. Tuning on the rolling road showed the MGTC was producing 80bhp at the rear wheels, almost double the factory offering and the most the dyno operator said he had seen from this type of MG engine on his equipment. The tuned MGTC made a stunning performance at Ellenbrook, Western Australia in May 2000. A sprint had been set up around the new roads and curbs of a subdivision yet to have houses built. Such an event was perfect for the small vehicle, with more than a few eyebrows raised at the performance - 56.4sec, placing it before fiftyseven other cars including Westfields, Porsche 911s, Nissan Skylines, BMW M3Rs, a Holden VT Commodore HSV GTS, &*#@ GTHO, Lotus Elise's, Alfa Romeo's, Jaguar E Type and Datsun 260s.

While the car was performing strongly, overheating was becoming a problem on the longer events. In November of 2002 the head gasket let go at the Wanneroo Historics meeting. Tear-down showed a totally destroyed head gasket. To combat the problem, Michael tried blocking off all the water holes between head and block with cast iron inserts, though this lead to the engine running too hot. The final solution (in December 2003) copied the factory race engines, where a 1" pipe is run from the top rear core plug to the back of the cylinder head. The MGTC has run in this guise ever since with no gasket failures and at the coolest of temperatures.

Sadly, in May 2004 disaster struck in the middle of a motorkhana. The Wray seized and stopped dead, with the engine spinning at some 6000rpm. One drive belt snapped, but the other belt kept driving. The supercharger had swallowed one vane and cracked the other three. The tear-down showed the Wray driveshaft had a 270º twist, with the pulley key disintegrated. The casing liner was 0.040" out of round, and the rotor slots opened up. After some major repairs, the Wray returned to service, thought he increased clearances would only support 8psi of boost. Michael sold the Wray, which made it’s way to Vancouver, Canada. The MGT has since been Roots-blown. The photos below, from Mike, show the Wray-blown track terror:

6. Fred Radman and the Second Generation of Wray Superchargers

The Wray superchargers were largely being sold in batches to speedshops. Once the speedshops mark-up was added, the superchargers became expensive. The lack of demand for superchargers, possibly due to the ability to install a V8 engine with cheap horsepower into various cars; and the lack of enthusiasm by John Wray and staff (who in previous years had an interest in performance vehicles) led to the stop in production. The drawings, patterns and tooling were sold in about 1986 to Fred Radman, starting a new era in Wray superchargers.

In the late 1970’s, Fred’s interest in supercharging was sparked by the noise coming from a motorkhana being held in a nearby shopping centre carpark at Tea Tree Plaza, Adelaide. On investigation, Fred found one of the competitors to be running a Mini Moke, complete with Formula 5000 slicks. The owner of the vehicle was Rob Searle. Rob was serious about his motorkhana vehicles, having competed in a Morrie ute powered with a supercharged Holden 138 grey motor the year before. Rob had purchased a steel case/steel rotor air cooled Type 65 Norman in pieces, with one end plate missing and no vanes. Having remade the missing components, the Norman was mounted to the grey motor and fed by twin Strombergs in suck-through mode. The Norman was later transferred to the 1275cc Moke engine, and chain-driven. A custom cam was ground up by Chris Milton Motors. Rob found that the suck through system experienced throttle lag, and modified it to run blow-through. A single SU carburettor was mounted in a pressurised box, made from an old saucepan. The SU would later be replaced with a Reece Fish carburettor. A Stromberg throttle body was employed as a waste gate, controlled by flexing a Holden fuel pump diaphragm to begin wasting at some 15psi of boost, Under load, the induction and exhaust noise of the little brick engine was incredible. (photos: Fred Radman)

Rob would later go on to wreck out the Moke, selling the Norman to Dennis Boundy to place into a Holden museum. The ex-Moke Norman supercharger is shown in Dennis’ photo below:

Dennis is no stranger to Norman superchargers… his Norman blown FJ sedan is legendary for running some 113mph on the Lake Gairdner Great White Dyno. The FJ runs a water cooled Norman, mounted on the drivers side of the grey motor and fed by a 350 Holley. The water cooling is run through a water/air intercooler. Dennis’ photo of the Norman blown FJ are below:

A few years later, with the noise of the Norman-blown Moke still ringing in his ears, Fred went on to purchase his first supercharger. This was a small model Wray, which had come from a Renault 8 or Renault 10. A few years later still a second Wray was purchased, again small model complete with a Mini fitment kit. The earlier supercharger was onsold to Kevin Shearer, whilst Fred still has his second supercharger.

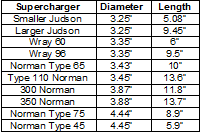

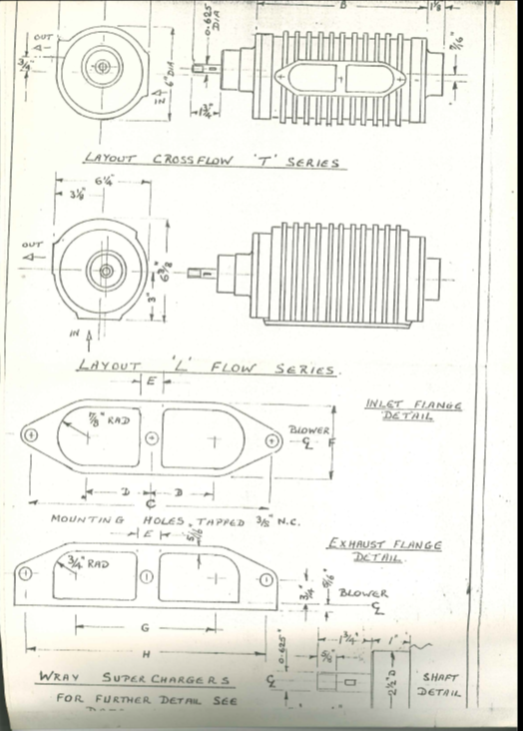

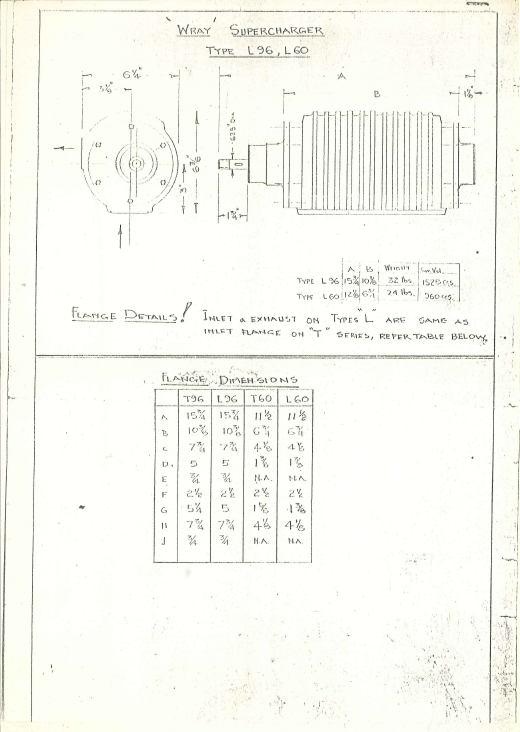

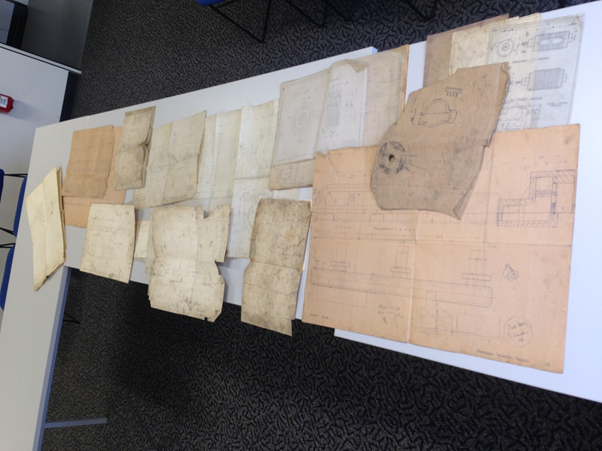

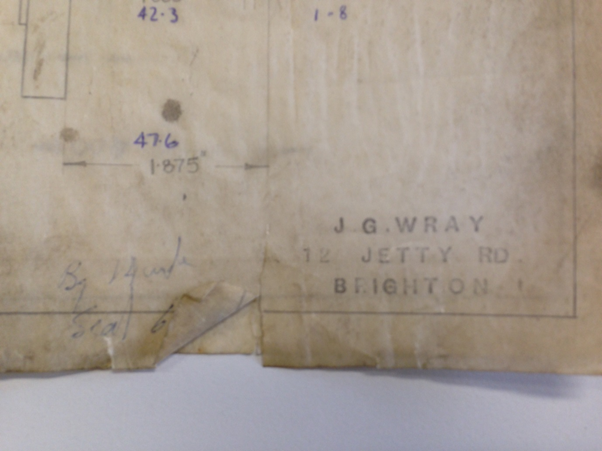

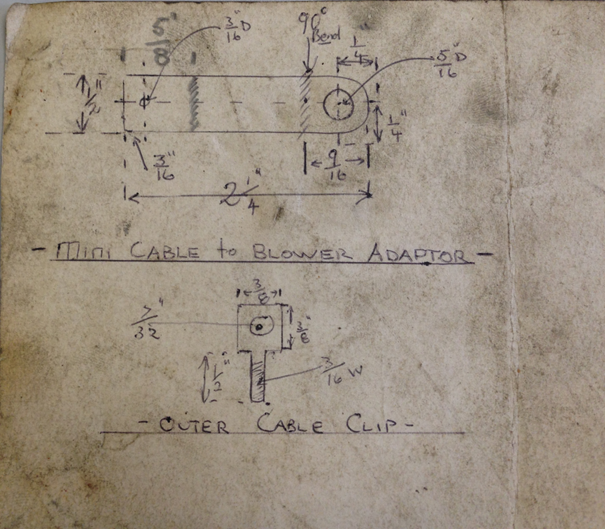

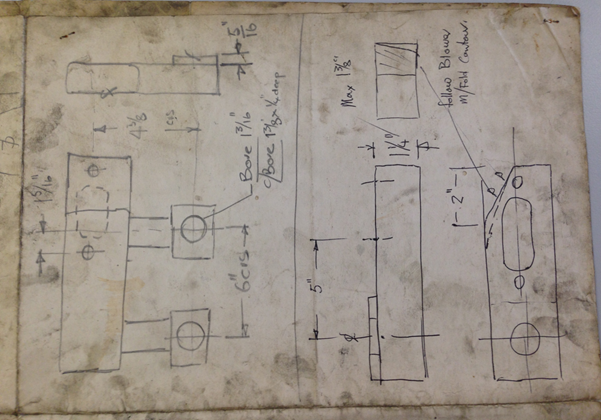

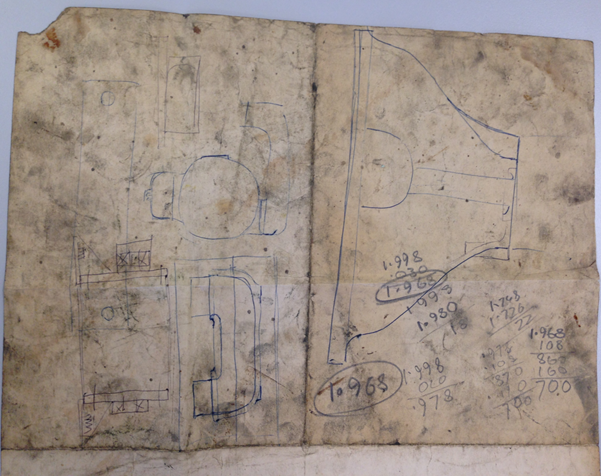

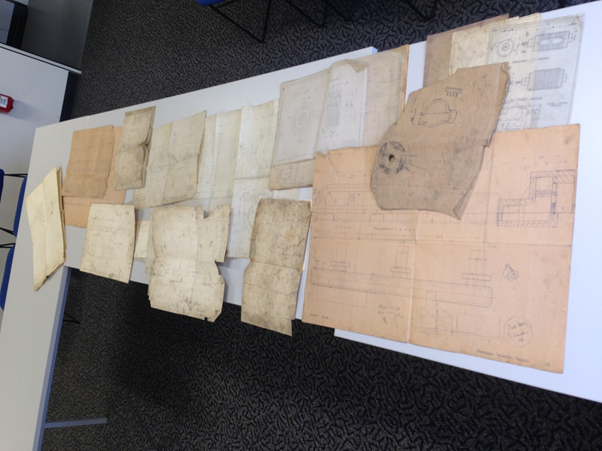

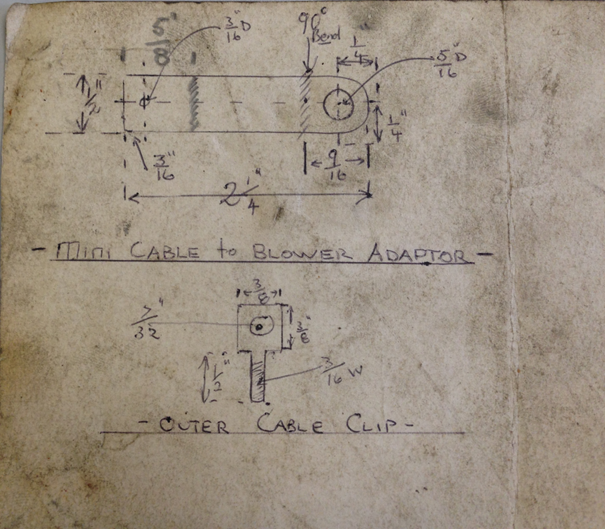

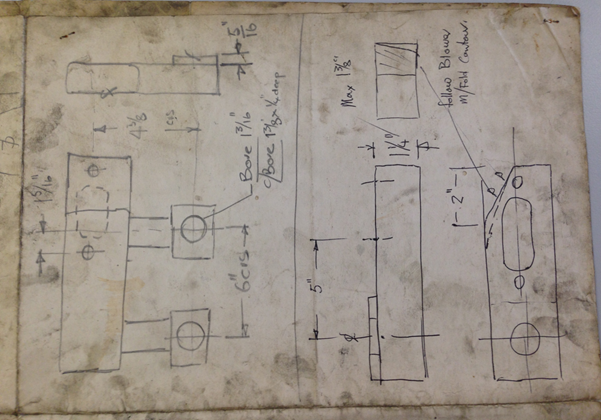

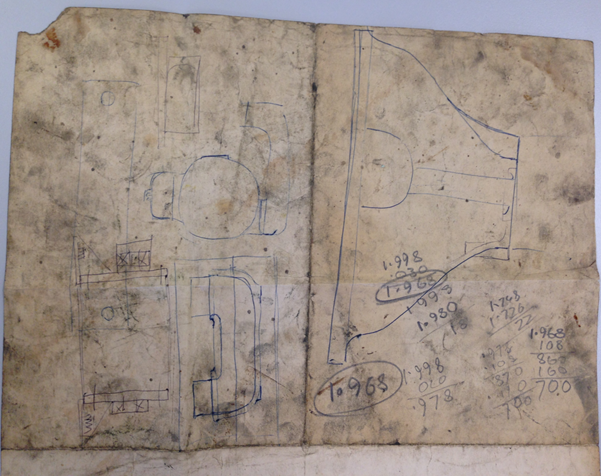

In the late 1980’s, Fred got into contact with John Wray, who in turn directed him to a Greg Pill, who had worked for Wray and had the moulds and tooling. This was around the time that the final batch of twelve superchargers was being made the MG TC Owners Club of Perth. Fred can remember meeting John Wray, who carried a small book of engineering details Fred purchased the casing moulds and tooling, and went on to cast his first supercharger. Pictured below are some of the drawings, sketches and doodlings which came with the moulds and tooling (photos: Fred Radman):

The pink drawing in the upper photo nearest the camera is a Holden grey motor manifold (sadly, no patterns or jigs exist for this one).

The small foundry used for Fred’s first casting run in Magill, Adelaide did not produce a satisfactory casting, and Fred changed to the Castech foundry (in Wingfield, South Australia -

http://castech.net/) for all subsequent work. The casing castings for the Radman superchargers were done in CC601 (A356/A357) aluminium alloy, which was later heat treated. Machining of the raw castings was undertaken by Bob Jolly. Bob was an ex-Isle of Man bike racer who competed across Europe in the mid-1970s. Bob also scratch built JAP, Velocette, Triumph and Norton gear. He was also the owner of Bob Jolly and Co Machining, which still exists:

http://bobjolly.com.au/.

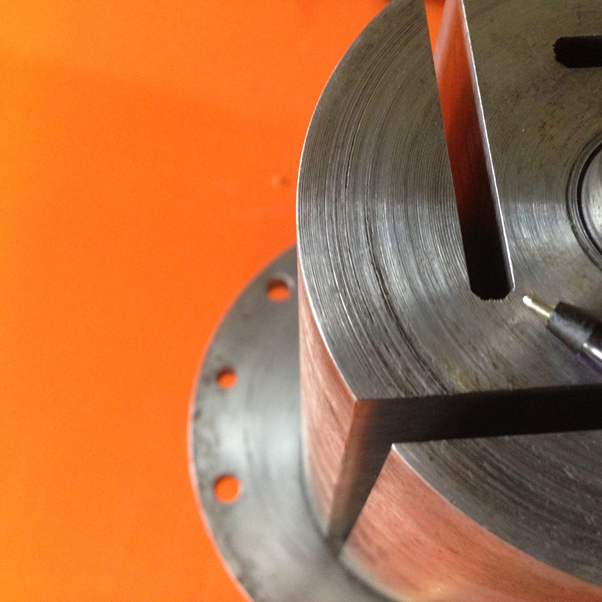

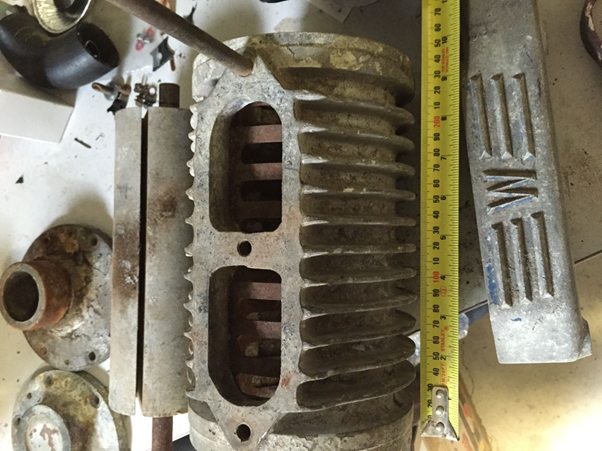

Bob's company was started in 1979 as Bob Jolly and Co Racing, with simple turning and milling operations servicing the racing community from his St Peters, Adelaide workshop. Bob relocated his workshop to Lobethal in the Adelaide Hills, and then to 82-84 Francis Road Wingfield, where they still operate today. All the rotors machined by Bob have distinctive rotor vane slots. The profile of the slitting saw used gives radiused roots, which lowers root stress in the rotor. The photo below (from Fred) shows the radiused vane root profile:

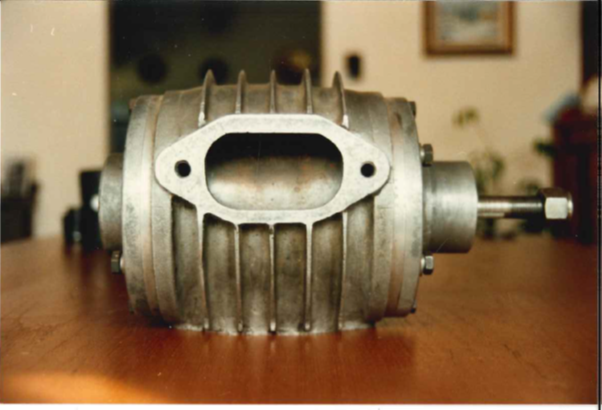

Fred went on to make L60, L96 and T96 machines, along with one T60.

Fred had been told by John Wray that cast iron diesel cylinder liners were used as casing liners in the Wray superchargers. For Fred’s machines, steel bore casing was used, with diagonal ports. Unlike the original Wray superchargers, Fred’s machines had the liners honed. Rotors were machined from 6060 or 6061 aluminium alloy. Like the earlier Wrays, the vanes were made from Tuffnol, which Fred sourced from Cadillac Plastics in Adelaide.

Fred also has the patterns for the Mini and T96 inlet manifolds. The latter can be machined for a single barrel downdraught carburettor, or cut to suit a side-draught SU or injection throttle body.

The Radman superchargers mainly used downdraught Stromberg carburettors with a variable main metering jet. Pictured below (photo: Fred Radman) is a D5 factory down draft S.U carburettor, used on the early Radman Mini setups. The adaptor mates it to the stud pattern on the intake manifold. Whilst it worked well it was not an easy carburettor to source, and Fred soon changed to Stromberg carbs for ease of availability.

Authors note: I have named the second generation of machines (made by Fred) Radman superchargers, to differentiate them from the Wray supercharger. Fred is modest, and views them as Wrays. I personally think though that anyone who manufactures superchargers from scratch, and continues their development deserves more than a little recognition… hence I’ve kept the Radman naming.

Around one dozen of the Radman superchargers were made, with the finished machines selling for cost at around $1000. Some of the superchargers were stamped with model and serial numbers, whilst others were not. The first of the Radman superchargers was sold to Peter Wilson in Adelaide on the 15th of January 1993 as a “kit” of parts. The liner was not machined for inlet/outlet ports, with Peter undertaking his own port timing. Peter built a Morris 8 special, named Pieces of Eight. Pieces of Eight was built in South Australia between 1988 and 1990, based on a 1937 UK Morris 8 special. It is a fully CAMS accredited Group K vehicle. It has a Morris 8 four-cylinder side valve engine, with the supercharger running at 12psi. It runs a single 1¾” SU on avgas. The car has finned 8” brakes driven by original 1935 hydraulics. Suspension is by Hartford friction shock absorbers, keeping the bounce out of 16”x3½” Dunlop magna wire polished alloy wheels.

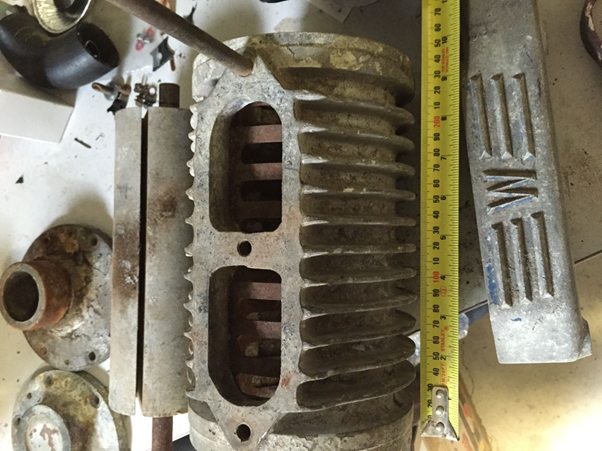

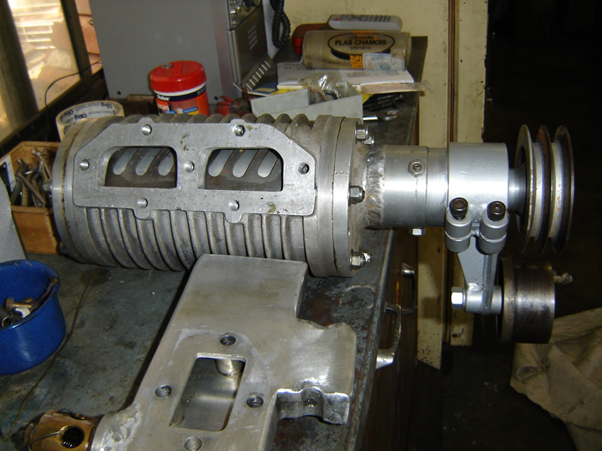

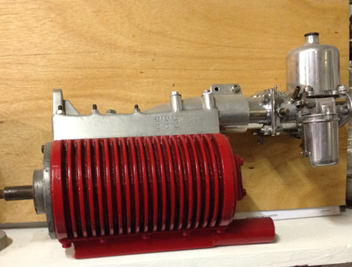

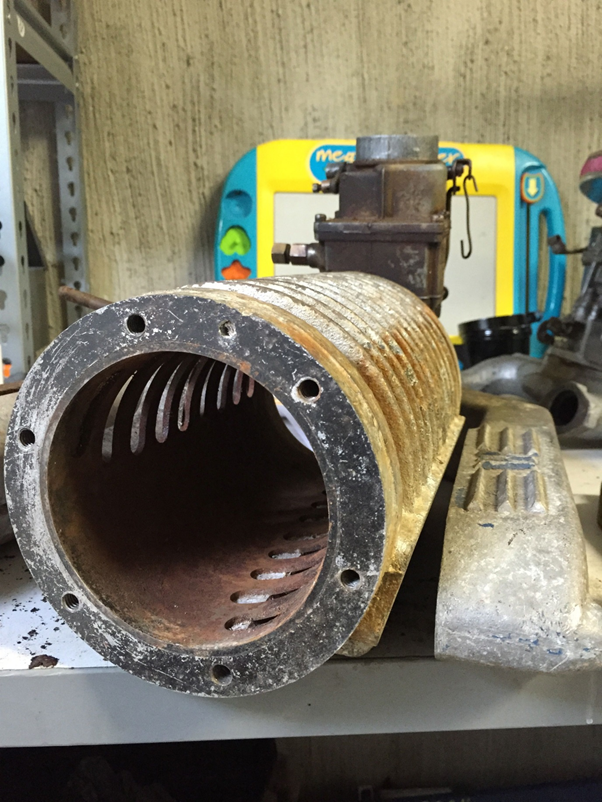

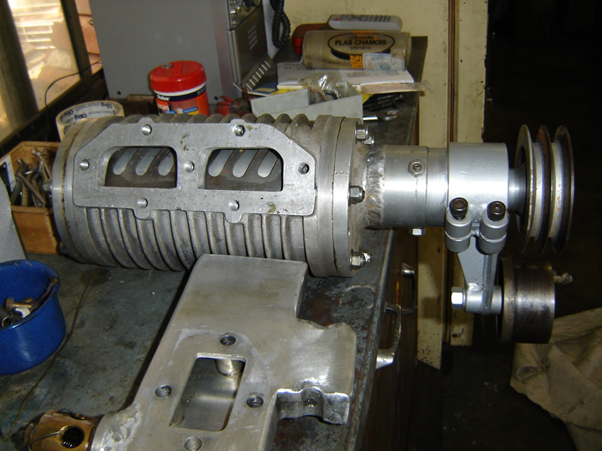

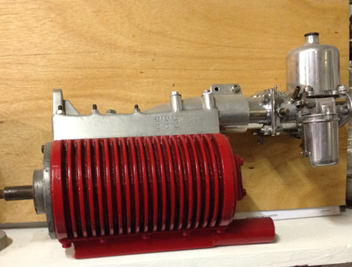

The images below (photos: Fred Radman) shows the original Radman supercharger made for Pieces of Eight, along with the original 2” SU carburettor supplied. To fit between the dumb irons on the chassis it was machined down so as to have only one bearing on the input end. The supercharger is directly driven from the Morrie’s crankshaft.

After the car was sold the supercharger rotor was subsequently shortened and a spacer fitted inside the casing to lower the capacity. Such modifications, whilst unusual, were not unique. Bob Jolly took a T96 casting and cut and shut it to make a T60 for Dave Linton (perhaps the only T60 ever made). Jim Howard from Slider Engineering hard anodised the rotor and also machined and anodised the tooth belt pulley. The cut and shut T60 unit would later be fitted to an Austin 7 race car.

The second Radman supercharger was also sold to another Morris 8 owner, with a further Radman going to an Alfa Romeo-powered Amilcar.

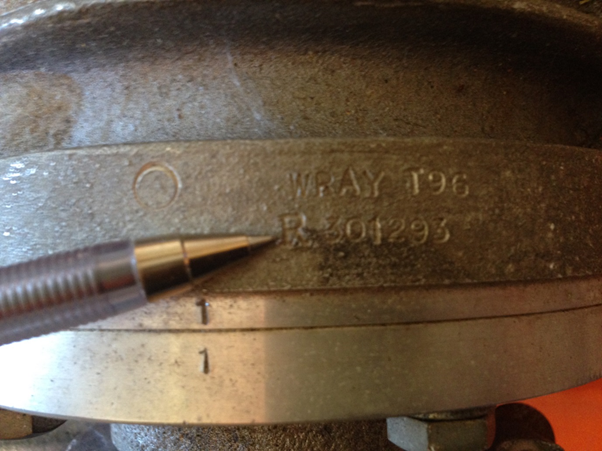

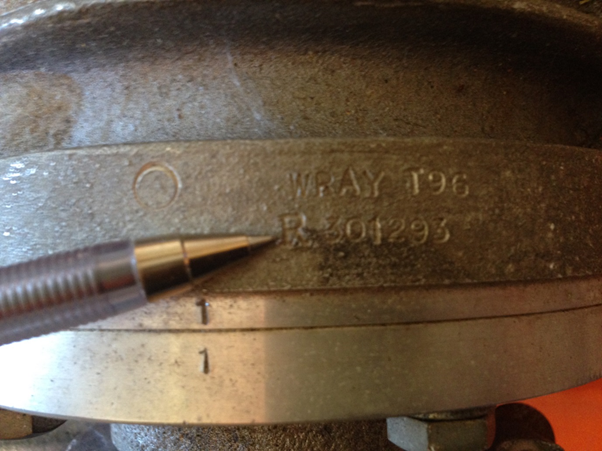

Fred moved to the UK, with sales of the Radman Wrays continuing in his absence by Bob Jolley, Dave Linton and Phil Evans. When Bob sold a supercharger, he often stamped a small “R” (for Robert) into the casing. The “R” is shown in the image below of a T96 Wray (photo: Fred Radman).

Fred sold two superchargers whilst in the UK to John Bibby, who rebuilt Shorrock and other superchargers. John still trades as John Bibby Superchargers (72 Feiashill Road Trysull Wolverhampton West Midlands WV5 7HT). The image below (photo: Fred Radman) was taken in the UK at John Bibby’s place, and shows a Cozette eccentric vane supercharger, a Wray L60 sliding vane supercharger and a Shorrock C75 eccentric vane supercharger.

Whilst in the UK Fred continued his research, speaking to Tuffnol about improved vane materials.

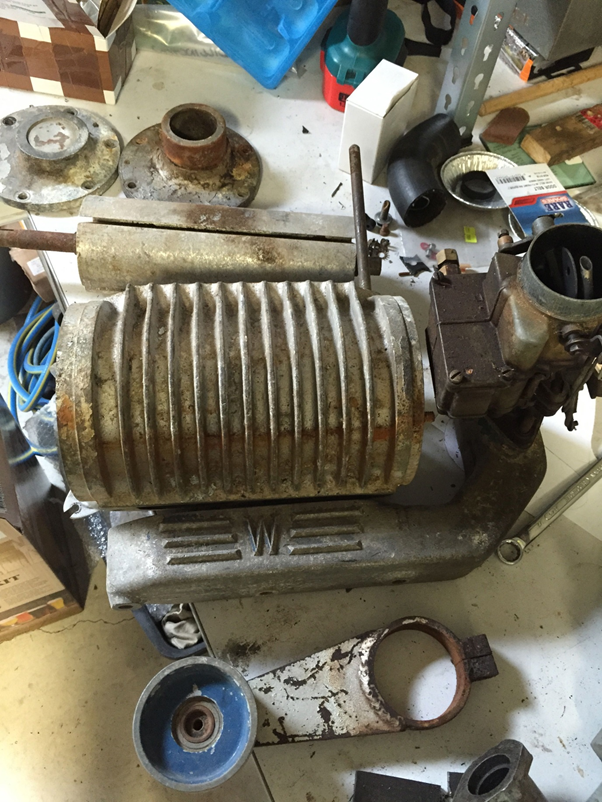

Sadly, the increasing availability of the Aisin superchargers used by Toyota reduced the market for the Radman superchargers, and no further batches were made. Fred still has a number of the castings and complete machines – the photo below (photo: Fred Radman) shows a manifold Fred recently machined:

Regards,

Harv (deputy apprentice Wray supercharger affecionado).