The ported vacuum trial didn't work that well. On deceleration it sucked the piston to the top of its travel lol. I should have thought of that happening.

Anyway, one thing got the better of me. It stuck in my mind that it always takes more force to initially move something than to keep it moving. These carbs (HIF type SU) were always spec'd with ball bearing suction chambers. I never fitted them, and stayed with the old style. They looked better, and you could run large or small diameter piston springs, which gives you more options with combinations of the two types. These older ones always had a slight drag due to oil/fuel film on the piston tube and the suction chamber (very close tolerance).

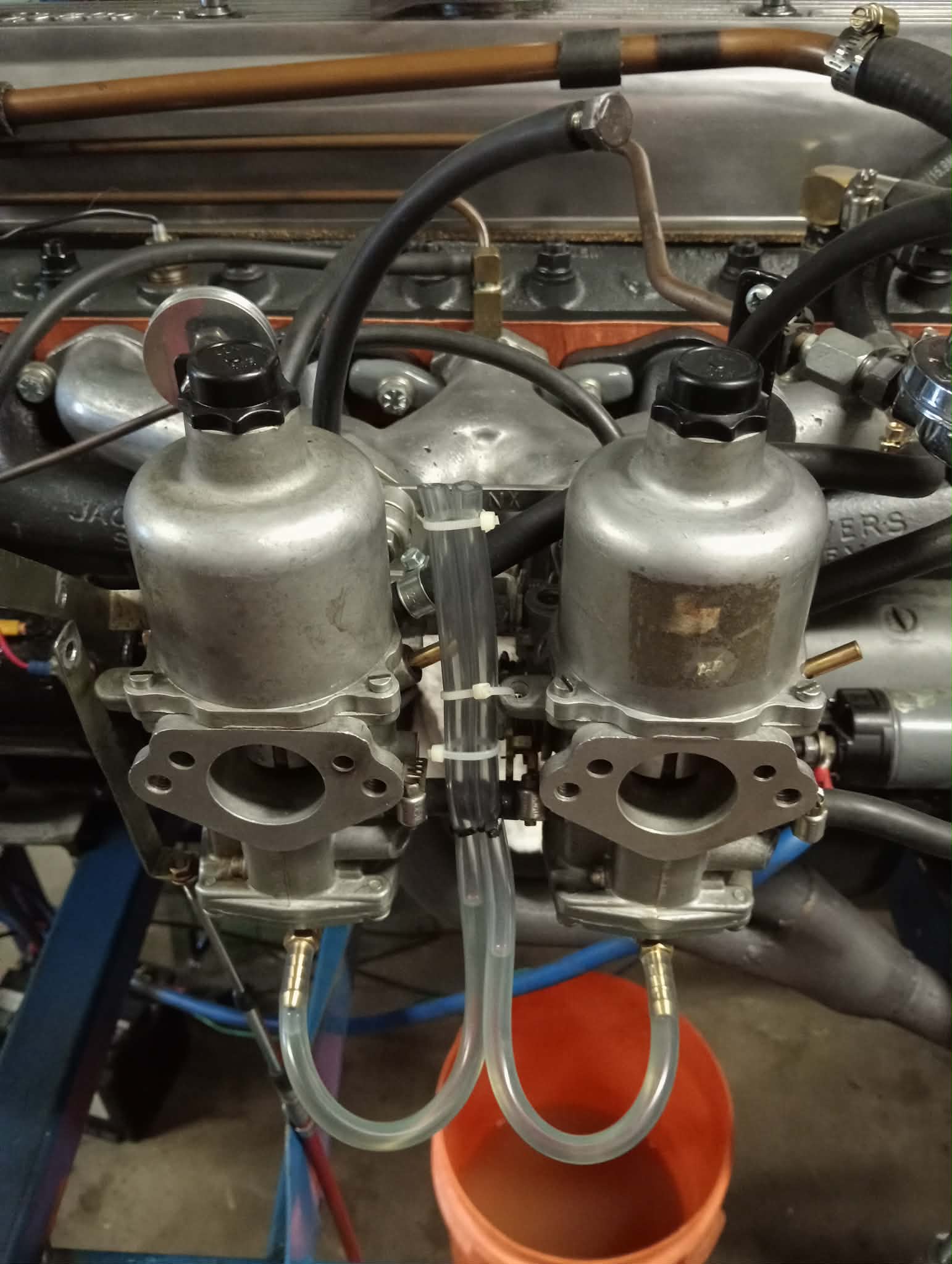

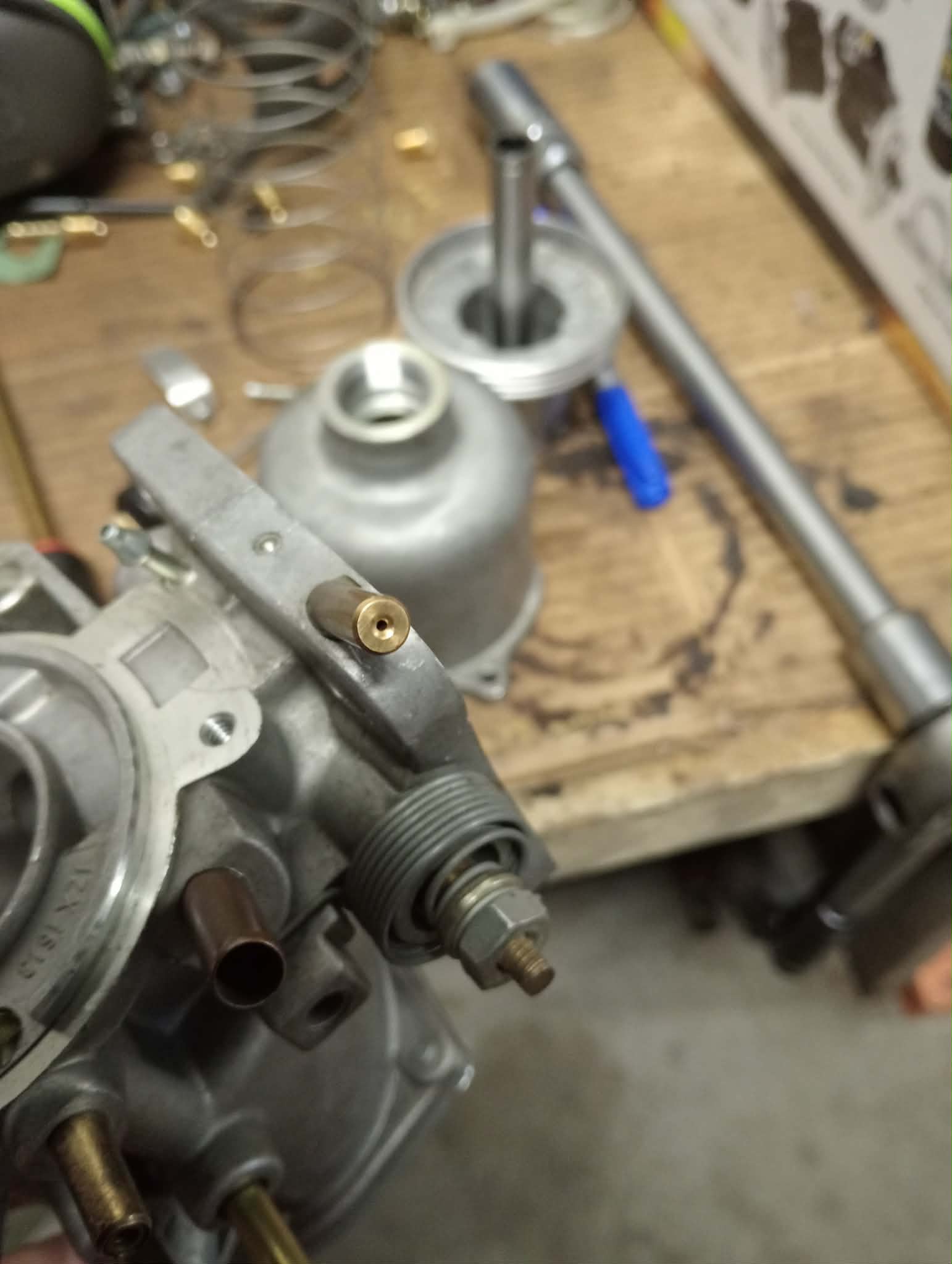

As my initial problem was going rich during the first part of the piston lifting, I decided to try the ball bearing chambers. Low and behold, it has dramatically improved. I'm now going to go with running the low pressure suction restrictor on the float bowl vent line. Using the manometer tubes, and with the vacuum line fitted to the float bowl vent tube, I can see and control the amount of fuel drop in the main jet. I just have to get the restrictor the right size so excessive fuel isn't leaned out at higher airflow through the carby. Good thing I have one to measure with some jet drills.

Point to note, the fuel bowls are still vented normally to atmosphere. The vacuum via the restrictor is teed into this line. I was quite suprised how little negative pressure you need to alter the fuel level in the jet. It's not even readable on analogue vacuum gauge at idle, but drops the fuel level an inch or so.

It also look like I have to polish up another set of vacuum chambers now!

- e6b5e690-ece7-4642-8f3f-da7871df7aa3.jpg (154.09 KiB) Viewed 32 times

- 67a0aa65-8b77-4f39-a013-3a4a70f83e47.jpg (127.91 KiB) Viewed 32 times

- 2add9bae-5ba4-4695-9818-0a5c3f268157.jpg (111.8 KiB) Viewed 32 times