Time to think a little bit about blower pulleys. Whilst vee-belts are traditional fare for road-going Normans, the dragster versions often got treated to gilmer belts. Part of me likes the idea of vee-belt tradition, but the other part of me says that there are a lot more choices of gilmer pulleys. This thing will likely have a few changes of pulley ratio before I get it right, so a gilmer belt is the right choice.

Two options make sense for the gilmer belts. I could go the traditional ½” pitch trapezoidal belt, or the more modern 8mm round belt. There are a lot more choices in the 8mm pulleys available, the pulleys are available locally-made, and belts are easier to find… so an 8mm belt is the right choice.

There are a couple of overseas companies that make the 8mm pullies, with a lot of local shops (eg Rocket Industries) stocking Blower Drive Service (BDS) pullies. There is also a local made option through Diecrest engineering, at about 25% cheaper. I can’t see any warning signs about the Diecrest products, so will give them a go.

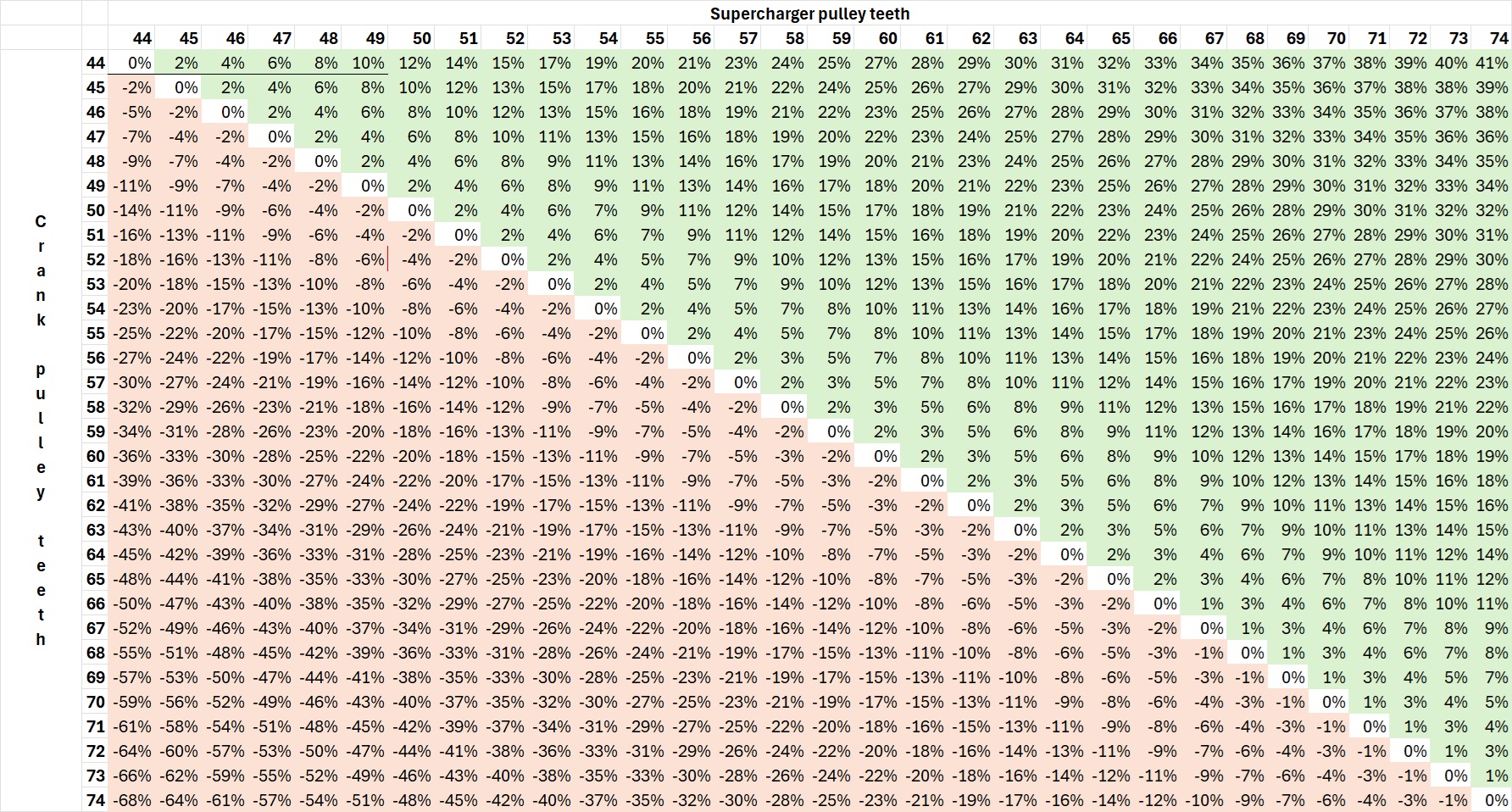

Diecrest make the gilmer pulleys in 43 to 74 teeth options, and can drill to suit. This gives the following ratio options:

- Diecrest 8mm pulley ratios.jpg (931.78 KiB) Viewed 7368 times

The green area is overdriven, whilst the orange side is underdriven. Most Norman superchargers are run at 1:1 ratio, or 10% overdriven. This is where I need to be a little careful though. Your average Norman sits on a grey motor with a moderate redline (say 4800rpm). At 10% overdriven, the supercharger sees up to about 5300rpm, which is close to the sensible limit for a sliding vane supercharger. Spin them any faster, and they make a lot of heat, and not much more pressure. The FED will start out each race sitting just below the torque convertor stall speed (5000rpm). As it passes the traps, it will see up to 7600rpm. A 1:1 pulley ratio would be OK (just) at the start line, with the supercharger seeing 5000rpm. At the finish line, the poor thing would be whizzing out to 7600rpm. A little too fast, so I suspect this thing will need to be underdriven.

Back in the first few pages of my Norman supercharger thread I showed how to estimate the power output for various supercharger specs. I ran these calcs again for the FED, with the following changes:

a) I increased the supercharger capacity from the small Type 45 one in the example (83ci/rev) to the Type 110 that I will use on the FED (145ci/rev).

b) I’ve increased the “factory” power output from 75BHP to 138BHP to account for the Repco head (using the Repco power curves as a guide).

c) I have assumed that the Repco head grey motor engine volumetric efficiency (VE) is 85%, rather than the 80% I assumed for the standard asthmatic grey motor head.

d) I have assumed that the Norman supercharger volumetric efficiency drops from 90% to 87% as the pressure increases above 10psi.

e) I have assumed that the Norman supercharger drive power efficiency reduces from 90% to 86% as the pressure increases above 10 psi.

f) I have assumed that the ambient air temperature will come down by 5ºC to 35ºC to account for the methanol vapourisation (a 40ºF drop is typical for top alcohol cars).

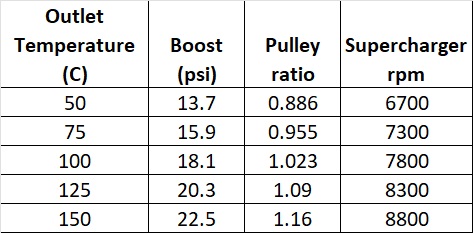

Running the numbers through says that to make the 220HP I need (for a 10.99s quarter mile in a 1300lb car) then the blower will need to be at 22psi and will run 168ºC outlet temperatures. This is probably not achievable with a Norman, as the blower would need to run at 8800rpm…. lots of churn, lots of heat, stuff-all power. Normans can run at higher boost (the Type 110 I am using was running 30psi on a Toyota), but heat is the issue. Depending on how well I can get the discharge temperature down, then I need less and less boost to make the 220HP. I can get discharge temperature down by:

a) running as rich as all hell – methanol does not drop off power if you run very rich… it just gets harder and harder for the plugs to ignite.

b) injecting water into the outlet (… just as easy to run the methanol fat).

c) Keeping the inlet manifold chilled with ice before each run.

The numbers look like this:

- FED engine outelt temperature.jpg (42.99 KiB) Viewed 7368 times

So where to start? Methinks underdriven as a starting point, at around 0.886:1 pulley ratio (11.4% underdriven). This is still whizzing the supercharger at 6700rpm, and assumes I can magically get down to 50ºC outlet. Will need to play from there – try a higher ratio to overcome the outlet heat, or a lower ratio to make less heat in the first place.

I’ll try a 53 tooth pulley on the crank, and 59 tooth on the supercharger as the starting point (10% underdriven).

Cheers,

Harv

327 Chev EK wagon, original EK ute for Number 1 Daughter, an FB sedan meth monster project and a BB/MD grey motored FED.