EK Wagon project - Total rebuild

Re: EK Wagon project - Total rebuild

Ok, Finny - we can rule out a head gasket between #5 & #6.. they would both be pretty low and about equal.

Plugs... maybe - but it wouldn't be the root cause of the issue.... as these plugs would have been in it before - and the run down to the rego place before extractors were fitted proved the motor to be ok.

Yes, by all means - chase down the equivalent for those AC46's... the BP5ES sounds familiar to me... long time since I played with a grey.

Your compressions explain why #5 made the least amount of difference in the balance test - #6 might just have been a dirty plug.

If you can afford one, please consider a timing light - don't go over the top, but a powered light would be a great asset - the old neon ones were pretty hard to use.. but extremely cheap.

I won't type any more for now - there's lots to check in my previous.

I am very much hoping you don't have to strip that carby down - we can do a lot of extra work and set ourselves up by putting further faults on this motor.

For my compression test - I use a bracket clip to hold the throttle fully wide open with all plugs out. I then fit the unit to each plug and crank it over until the highest reading is attained.

that's all this time,

frats,

Rosco

Plugs... maybe - but it wouldn't be the root cause of the issue.... as these plugs would have been in it before - and the run down to the rego place before extractors were fitted proved the motor to be ok.

Yes, by all means - chase down the equivalent for those AC46's... the BP5ES sounds familiar to me... long time since I played with a grey.

Your compressions explain why #5 made the least amount of difference in the balance test - #6 might just have been a dirty plug.

If you can afford one, please consider a timing light - don't go over the top, but a powered light would be a great asset - the old neon ones were pretty hard to use.. but extremely cheap.

I won't type any more for now - there's lots to check in my previous.

I am very much hoping you don't have to strip that carby down - we can do a lot of extra work and set ourselves up by putting further faults on this motor.

For my compression test - I use a bracket clip to hold the throttle fully wide open with all plugs out. I then fit the unit to each plug and crank it over until the highest reading is attained.

that's all this time,

frats,

Rosco

Re: EK Wagon project - Total rebuild

What an interesting afternoon.

Yes Rosco I have a timing light.

Spark plugs all removed again.

The NGK BP5S (which was the match for Ek and EJ motors) is definitely a lot shorter than the BP5ES.

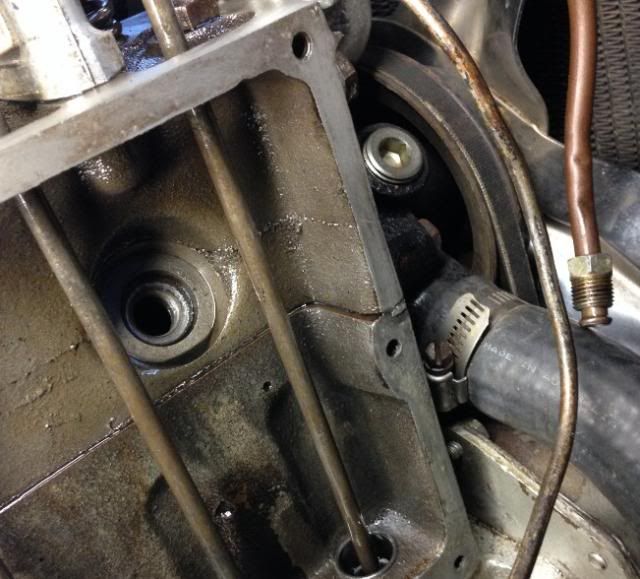

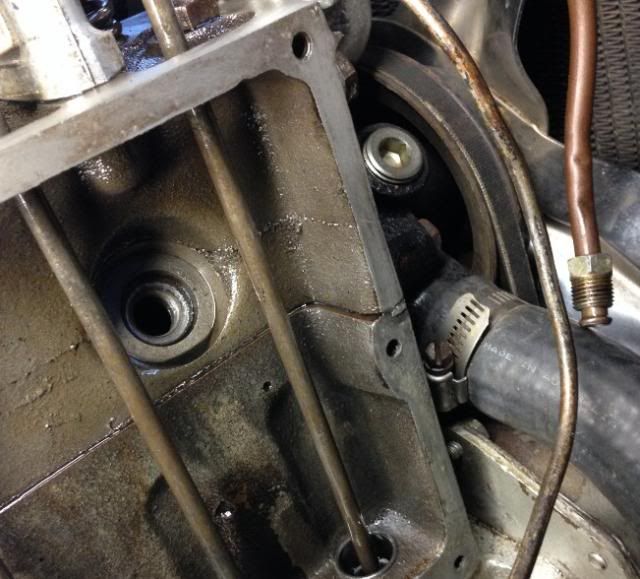

Needed to replace the sideplate and tappet cover gaskets to stop the oil leaks.

Also needed to check the points before timing, so figured I'd pull out the distributor anyhow and do it all at the same time.

(The oil leaks are quite bad and a priority anyhow. So I'd need to pull all this stuff off again anyhow)

Discovered I also had to disconnect the fuel pump pipe in order to get the sideplate off. What a pain.

Also a pain to get some of the screws out.

So ended up with this.

Tappet cover gasket fits fine.

But the sideplate gasket is the wrong one, or I am missing something.

The one I have seems to fit inside the other one, and wouldn't actually stay in place because their is nothing on the inside to push against

Also noticed that both ends seem to have a joint that is not level or smooth.

It that normal ? I assume it is, but would certainly challenge the gasket to seal over it, without some extra sealant.

So car wont be going anywhere or running again until I get this finished.

Just hope I can get a sideplate gasket from somewhere without too much delay.

Once I have these addressed I can run the engine again and continue with some tests and a power drive.

Not sure If I actually want it to run well or not. The devil you know or a new one.

PS. Haven't taken the gearbox out yet.

But it was getting very hard to select gears (including 2nd), crunching again on 1st and reverse.

Yes Rosco I have a timing light.

Spark plugs all removed again.

The NGK BP5S (which was the match for Ek and EJ motors) is definitely a lot shorter than the BP5ES.

Needed to replace the sideplate and tappet cover gaskets to stop the oil leaks.

Also needed to check the points before timing, so figured I'd pull out the distributor anyhow and do it all at the same time.

(The oil leaks are quite bad and a priority anyhow. So I'd need to pull all this stuff off again anyhow)

Discovered I also had to disconnect the fuel pump pipe in order to get the sideplate off. What a pain.

Also a pain to get some of the screws out.

So ended up with this.

Tappet cover gasket fits fine.

But the sideplate gasket is the wrong one, or I am missing something.

The one I have seems to fit inside the other one, and wouldn't actually stay in place because their is nothing on the inside to push against

Also noticed that both ends seem to have a joint that is not level or smooth.

It that normal ? I assume it is, but would certainly challenge the gasket to seal over it, without some extra sealant.

So car wont be going anywhere or running again until I get this finished.

Just hope I can get a sideplate gasket from somewhere without too much delay.

NO. Checked that.is there any chance that you have somehow managed to foul the carby connecting lever from the throttle shaft to the choke control lever?

NO Checked that also. Works fine.Next question - have you checked that your choke is fully open?... with the dash knob fully in?

Once I have these addressed I can run the engine again and continue with some tests and a power drive.

Not sure If I actually want it to run well or not. The devil you know or a new one.

PS. Haven't taken the gearbox out yet.

But it was getting very hard to select gears (including 2nd), crunching again on 1st and reverse.

IT's LIKE WATCHING DRUNK MONKEYS TRYING TO HUMP A FOOTBALL.

Re: EK Wagon project - Total rebuild

That side plate gasket is just the inner piece that the real gasket comes off, it gets thrown out.

[img]http://i47.photobucket.com/albums/f177/trevwood/WOOFTOsmall.jpg[/img]

Woofto Car Club Member No3

Woofto Car Club Member No3

Re: EK Wagon project - Total rebuild

Ok Finny,

Great pix.

let me know when you're back in business to run the motor.

Yes Trev, correct - Finny, where did you get that gasket from? - and, there should be six circular gaskets as well which go around the spark plug holes.

I'm relieved that you have a timing light - I might have suggested checking the timing before removing the distributor.. we don't know where it was set now.... but when it goes back in - you'll will set it, so that's one out of the way.

What were the faces of the points like?

Ok - we can rule out the throttle link/choke possibility.

Please don't touch the carby yet - with the distributor now out - and new plugs, it will be a good base to work from when they are re-fitted.

The gear box issue sounds like adjustment... from memory, someone posted up a similar issue coming home from the Wangaratta nats....

I'll wait now until you post some more up.

frats,

Rosco

Great pix.

let me know when you're back in business to run the motor.

Yes Trev, correct - Finny, where did you get that gasket from? - and, there should be six circular gaskets as well which go around the spark plug holes.

I'm relieved that you have a timing light - I might have suggested checking the timing before removing the distributor.. we don't know where it was set now.... but when it goes back in - you'll will set it, so that's one out of the way.

What were the faces of the points like?

Ok - we can rule out the throttle link/choke possibility.

Please don't touch the carby yet - with the distributor now out - and new plugs, it will be a good base to work from when they are re-fitted.

The gear box issue sounds like adjustment... from memory, someone posted up a similar issue coming home from the Wangaratta nats....

I'll wait now until you post some more up.

frats,

Rosco

Re: EK Wagon project - Total rebuild

Finny,

I just checked on line with both NGK and AC Delco.

According to both, you have the correct plug fitted - the BP5S - AC no longer make the old AC46 but have re-named it to AC R43S.

The long reach plug you showed is for the red motor - BP5ES.

I'm "pasting" part of what I put together on spark plugs below - learned a lot, the NGK site is very informative - except for any specifications on each plug.

The IMEP column is the heat range - the lower the number, the hotter the plug. The 240 is a hot plug.

I can't locate the technical details for NGK plugs - they only give you a "finder" which states the plug for each vehicle.

Make reach IMEP Thread pitch Socket

FB EK EJ

AC R43S 9.40 mm (3/8”) 240 M14 x 1.25 13/16”

NGK BP5S

EH – HT 149-186 cu. In.

AC 43XLS 19.05 mm (¾)” n/a M14 x 1.25 13/16”

NGK BP5ES

frats,

Rosco

I just checked on line with both NGK and AC Delco.

According to both, you have the correct plug fitted - the BP5S - AC no longer make the old AC46 but have re-named it to AC R43S.

The long reach plug you showed is for the red motor - BP5ES.

I'm "pasting" part of what I put together on spark plugs below - learned a lot, the NGK site is very informative - except for any specifications on each plug.

The IMEP column is the heat range - the lower the number, the hotter the plug. The 240 is a hot plug.

I can't locate the technical details for NGK plugs - they only give you a "finder" which states the plug for each vehicle.

Make reach IMEP Thread pitch Socket

FB EK EJ

AC R43S 9.40 mm (3/8”) 240 M14 x 1.25 13/16”

NGK BP5S

EH – HT 149-186 cu. In.

AC 43XLS 19.05 mm (¾)” n/a M14 x 1.25 13/16”

NGK BP5ES

frats,

Rosco

Re: EK Wagon project - Total rebuild

Had the granddaughter over today so didn't get to the car until after 3pm.

But everything went back together first time, with no issues.

One of the quickest activities completed in a long time.

All back on.

New gaskets installed.

New spark plugs.

New air filter installed.

New wires for the coil.

Points set.

Fuel pump and vacuum advance pipes back on.

Started 2nd attempt after moving distributor.

Got the timing light on it to check timing.

That was on 22 deg when it first started.

Moved it back to 6 deg, but I'm not sure that's what it should be on.

No oil leaks from the installed gaskets.

But did notice some oil that appears to be coming from the bolt/screw, which is under the distributor.

Felt around and no leaks anywhere above it, so must be coming out of this area.

Is that something seen before ?

Crossed fingers and went for a drive.

Engine ran beautifully. no idle issues, reving or missing.

Did a video, so will try to upload it later.

Actually went around several blocks and up to about 80klm, and no issues.

So at this stage, I'm thinking the extractors and carby are fine.

Just that old co-incidence curse getting in the way,

May still need to identify why the plugs went, and if it's going to happen again.

I think I'll put it in for a professional tune up.

Also noticed that when I eventually stopped it, it struggled to turn over/start again, like the battery was drained.

Eventually started, and when I tried to start it again 15 minutes later it was fine, with lots of battery power.

Not sure what caused that one.

Just another fun quirk to discover and resolve.

But everything went back together first time, with no issues.

One of the quickest activities completed in a long time.

All back on.

New gaskets installed.

New spark plugs.

New air filter installed.

New wires for the coil.

Points set.

Fuel pump and vacuum advance pipes back on.

Started 2nd attempt after moving distributor.

Got the timing light on it to check timing.

That was on 22 deg when it first started.

Moved it back to 6 deg, but I'm not sure that's what it should be on.

No oil leaks from the installed gaskets.

But did notice some oil that appears to be coming from the bolt/screw, which is under the distributor.

Felt around and no leaks anywhere above it, so must be coming out of this area.

Is that something seen before ?

Crossed fingers and went for a drive.

Engine ran beautifully. no idle issues, reving or missing.

Did a video, so will try to upload it later.

Actually went around several blocks and up to about 80klm, and no issues.

So at this stage, I'm thinking the extractors and carby are fine.

Just that old co-incidence curse getting in the way,

May still need to identify why the plugs went, and if it's going to happen again.

I think I'll put it in for a professional tune up.

Also noticed that when I eventually stopped it, it struggled to turn over/start again, like the battery was drained.

Eventually started, and when I tried to start it again 15 minutes later it was fine, with lots of battery power.

Not sure what caused that one.

Just another fun quirk to discover and resolve.

IT's LIKE WATCHING DRUNK MONKEYS TRYING TO HUMP A FOOTBALL.

Re: EK Wagon project - Total rebuild

Thank Trev, that would be because I had already fitting a new one when I had the head done years ago.Trev wrote:That side plate gasket is just the inner piece that the real gasket comes off, it gets thrown out.

Obviously didn't throw that part away.

Now in the bin.

IT's LIKE WATCHING DRUNK MONKEYS TRYING TO HUMP A FOOTBALL.

Re: EK Wagon project - Total rebuild

Link to the video of it's drive.

Probably a little boring but you can hear it running well.

Turn up your speakers.

http://www.youtube.com/watch?v=Y5O_49uo ... e=youtu.be

Probably a little boring but you can hear it running well.

Turn up your speakers.

http://www.youtube.com/watch?v=Y5O_49uo ... e=youtu.be

IT's LIKE WATCHING DRUNK MONKEYS TRYING TO HUMP A FOOTBALL.

Re: EK Wagon project - Total rebuild

Ripper, Finny - I'm sure glad you didn't have to strip the carby.

If it was at 22 deg's advanced when it was playing up - that would have accounted for all the symptoms. At that sort of difference, it could have been that you re-fitted the dizzy one tooth out.

You know this, but the bottom of the distributor shaft has a flat tooth which must fit into the slot of the oil pump - Tim noted that your oil sender switch light wire was disconnected. If the dizzy is sitting up high due to that tooth not driving the oil pump - it would cause it to leak oil from the block - but more importantly - you won't have any oil pressure - and wouldn't note it, because the wire was off..... please go check both these things before starting the engine again.

Ok - timing..... timing light..... and tuning.

Yes, you could have it professionally done - but to be quite honest, they aren't going to get much more out of it than you can.

A new set of points and condensor - you're going to be charged for those anyway.. and they will also change your new plugs... it's part of the service price....

All that they will do is connect up to their analysis machine, replace the points/condensor and plugs, set the timing to the ball mark (which will be too retarded for an old engine) and adjust the idle mixture... plus check for leaks.

They will electrically do a balance check and tell you what you already know....

So, unless you want to throw some coupons their way for peace of mind... I believe you just about have tuned the engine yourself.

My final "tweak" in setting timing is to find a hill somewhere.

I take a ring spanner with me to loosen the distributor clamp just enough to bump the dizzy around a hair's width at a time.

In top gear at about 25 - 30 mph, I give it full throttle.

I set my timing to the point where the engine just starts to "ping"....one every second or so... not a continual one, and not one every 10 seconds - you aren't normally going to run the engine down so slow under full power... so you're not going to hurt it with pre-ignition.

Once I have the timing set, I put a fixed mark (I used a centre punch) on the timing cover and another on the harmonic balancer.

Checking the timing after that is a breeze with a timing light - be careful of the fan, though - my timing light has a few "nicks" in it.....

Of course, you can put a mark on the flywheel through the timing hole - but flywheels are made of very hard steel.....

Yes, like Tim - I'd like to be a lot closer to where you live.... we could have sorted this out for you in less than 1/2 hour...

frats,

Rosco

If it was at 22 deg's advanced when it was playing up - that would have accounted for all the symptoms. At that sort of difference, it could have been that you re-fitted the dizzy one tooth out.

You know this, but the bottom of the distributor shaft has a flat tooth which must fit into the slot of the oil pump - Tim noted that your oil sender switch light wire was disconnected. If the dizzy is sitting up high due to that tooth not driving the oil pump - it would cause it to leak oil from the block - but more importantly - you won't have any oil pressure - and wouldn't note it, because the wire was off..... please go check both these things before starting the engine again.

Ok - timing..... timing light..... and tuning.

Yes, you could have it professionally done - but to be quite honest, they aren't going to get much more out of it than you can.

A new set of points and condensor - you're going to be charged for those anyway.. and they will also change your new plugs... it's part of the service price....

All that they will do is connect up to their analysis machine, replace the points/condensor and plugs, set the timing to the ball mark (which will be too retarded for an old engine) and adjust the idle mixture... plus check for leaks.

They will electrically do a balance check and tell you what you already know....

So, unless you want to throw some coupons their way for peace of mind... I believe you just about have tuned the engine yourself.

My final "tweak" in setting timing is to find a hill somewhere.

I take a ring spanner with me to loosen the distributor clamp just enough to bump the dizzy around a hair's width at a time.

In top gear at about 25 - 30 mph, I give it full throttle.

I set my timing to the point where the engine just starts to "ping"....one every second or so... not a continual one, and not one every 10 seconds - you aren't normally going to run the engine down so slow under full power... so you're not going to hurt it with pre-ignition.

Once I have the timing set, I put a fixed mark (I used a centre punch) on the timing cover and another on the harmonic balancer.

Checking the timing after that is a breeze with a timing light - be careful of the fan, though - my timing light has a few "nicks" in it.....

Of course, you can put a mark on the flywheel through the timing hole - but flywheels are made of very hard steel.....

Yes, like Tim - I'd like to be a lot closer to where you live.... we could have sorted this out for you in less than 1/2 hour...

frats,

Rosco

Re: EK Wagon project - Total rebuild

Would be great to be a bit closer to help, but not moving at the stage.

Thanks Tim and Rosco for the offers.

Yes I haven't connect the oil pressure light wire.

It's one of the items on my "To-Do" list.

Needed to get a connector for the end of the wire, as I ran out.

I'm going to bleed the clutch next, and check the gearbox fluid levels (again).

I refilled the gearbox a few weeks ago, but it is probably one of the leaks underneath and is possibly low again.

Last time I filled it up, it did stop the grinding in first and reverse.

I assumed there was No gearbox fluid to slow it spinning.

The level was down quite a bit.

Thanks Rosco for the feedback.

The 22deg was just the rough setting that it first fired over on. (and seemed to run really freely on)

I lined up the timing ball mark before I removed the dissy, and check the points opening on cyl one.

And when I reinstalled it, I made sure it was aligned to fire on cylinder one again.

Not sure what is was previously, as I didn't check it.

I did a good check to see if there was any leaks from around or under the dissy.

And NO leaks, it was all dry and clean.

The Dissy is sitting in place correctly.

As far as the tune up goes. I was just wanting it diagnostically checked.

Set engine idle speed, mixture adjusted and timing mark.

Still not sure what degree I should set in on.

I didn't need to mark anything, just used the ball on the flywheel.

On my timing light it has a dial setting on the end, which adjusts the flash timing.

If I leave the setting on zero. then it operates normally.

But if I actually dial in the required setting (6 deg or whatever) and then move the dissy until the ball lines up with the mark.

So the only mark I need is the timing ball. Very handy little tool.

Just don't have anything to check idle speed or other settings.

Thanks Tim and Rosco for the offers.

Yes I haven't connect the oil pressure light wire.

It's one of the items on my "To-Do" list.

Needed to get a connector for the end of the wire, as I ran out.

I'm going to bleed the clutch next, and check the gearbox fluid levels (again).

I refilled the gearbox a few weeks ago, but it is probably one of the leaks underneath and is possibly low again.

Last time I filled it up, it did stop the grinding in first and reverse.

I assumed there was No gearbox fluid to slow it spinning.

The level was down quite a bit.

Thanks Rosco for the feedback.

The 22deg was just the rough setting that it first fired over on. (and seemed to run really freely on)

I lined up the timing ball mark before I removed the dissy, and check the points opening on cyl one.

And when I reinstalled it, I made sure it was aligned to fire on cylinder one again.

Not sure what is was previously, as I didn't check it.

I did a good check to see if there was any leaks from around or under the dissy.

And NO leaks, it was all dry and clean.

The Dissy is sitting in place correctly.

As far as the tune up goes. I was just wanting it diagnostically checked.

Set engine idle speed, mixture adjusted and timing mark.

Still not sure what degree I should set in on.

I didn't need to mark anything, just used the ball on the flywheel.

On my timing light it has a dial setting on the end, which adjusts the flash timing.

If I leave the setting on zero. then it operates normally.

But if I actually dial in the required setting (6 deg or whatever) and then move the dissy until the ball lines up with the mark.

So the only mark I need is the timing ball. Very handy little tool.

Just don't have anything to check idle speed or other settings.

IT's LIKE WATCHING DRUNK MONKEYS TRYING TO HUMP A FOOTBALL.

Re: EK Wagon project - Total rebuild

Above +1 - except for the timing light..

I tried using a dwell meter - and it drove me crazy.... +2 degrees here -2 degrees there.. might have been ok if I was able to tweak the dwell without having to re-set the points.... like some English cars could do....

But these old buses just love a mechanic's "ear".. and will love you for it...

Feeler gauges set my gap, timing light gets my dizzy set - the rest I do by ear.

Try the 25 mph pull in top gear under full load ping test.... I firmly don't believe you can set your timing better for power and economy.

The idle mixture setting is all "ear" .... screw it in until it struggles, screw it out until it rolls... then just screw it back in again until is becomes steady at the highest rpm (by ear)..... job done!

It's only when the motor goes sour that we need to look for a cause... points, plugs and carby.... if it's ticking away nicely - just let it do its stuff.... that's how simple they were designed to be.....

frats,

Rosco

I tried using a dwell meter - and it drove me crazy.... +2 degrees here -2 degrees there.. might have been ok if I was able to tweak the dwell without having to re-set the points.... like some English cars could do....

But these old buses just love a mechanic's "ear".. and will love you for it...

Feeler gauges set my gap, timing light gets my dizzy set - the rest I do by ear.

Try the 25 mph pull in top gear under full load ping test.... I firmly don't believe you can set your timing better for power and economy.

The idle mixture setting is all "ear" .... screw it in until it struggles, screw it out until it rolls... then just screw it back in again until is becomes steady at the highest rpm (by ear)..... job done!

It's only when the motor goes sour that we need to look for a cause... points, plugs and carby.... if it's ticking away nicely - just let it do its stuff.... that's how simple they were designed to be.....

frats,

Rosco

Re: EK Wagon project - Total rebuild

Rosco, I live in an unbelievably flat area.

Do you have a hill I can borrow.

Do you have a hill I can borrow.

IT's LIKE WATCHING DRUNK MONKEYS TRYING TO HUMP A FOOTBALL.

Re: EK Wagon project - Total rebuild

Pull the handbrake on, Finny...that'll do it..

frats,

Rosco

frats,

Rosco

Re: EK Wagon project - Total rebuild

I'm sure there's a bet on with people on this forum... counting each letter.... Rosco's posts..

Last one was probably my shortest..?

frats,

Rosco

Last one was probably my shortest..?

frats,

Rosco

Re: EK Wagon project - Total rebuild

Goes even faster with the handbrake on.

Will adjust it again.

Rosco, you can just reply with "OK".

Will adjust it again.

Rosco, you can just reply with "OK".

IT's LIKE WATCHING DRUNK MONKEYS TRYING TO HUMP A FOOTBALL.