Page 13 of 15

Re: Harv's FED thread

Posted: Sun Feb 11, 2024 9:03 pm

by Harv

Re: Harv's FED thread

Posted: Sun Feb 11, 2024 9:10 pm

by Harv

There is not much room between your ears and the burnout.

- IMG_0979.jpeg (3.23 MiB) Viewed 457 times

… or the diff and your vitals.

- IMG_0980.jpeg (2.79 MiB) Viewed 457 times

(note use of OSHA approved safety-socks).

Got the wiring done, and instrument panel mocked up in ply (6mm offcuts from gasket shipping… to be replaced in 6mm ally).

- IMG_0977.jpeg (1.48 MiB) Viewed 457 times

Starter momentary switch on the left, steering butterfly, magneto kill switch and red fuel cutoff cable. If things go pear-shaped, your left hand holds onto the butterfly for dear life. Your right hand pulls the chute, pushes fuel off, turns off the magneto and checks undies.

Cheers,

Harv

Re: Harv's FED thread

Posted: Sun Feb 11, 2024 10:32 pm

by Blacky

Not much room between your trailer and your toolbox either mate

Still spins me out that a grey powered anything needs a parachute

Re: Harv's FED thread

Posted: Sun Feb 11, 2024 11:15 pm

by FireKraka

Think you need a bigger shed mate.

Re: Harv's FED thread

Posted: Mon Feb 12, 2024 7:00 am

by Harv

I can walk (sideways) down one side of the trailer, and step over the drawbar to get at the bench. Anywhere else in the shed and I need to parkour.

Plan is to rebuild the shed. A little wider, a little longer and tall enough to fit a hoist. FB on the hoist, FED and trailer underneath. Of course, a shed that tall does not meet council guidelines. The existing slab is within 1m of a sewage main, so Sydney Water want a say too. I’m 12 months and $5k into the certification/engineering process of convincing both of them.

Cheers,

Harv

Re: Harv's FED thread

Posted: Mon Feb 12, 2024 7:59 am

by Errol62

Those wheels look sick Harv

FB ute fixer upper, EK van on rotisserie

Re: Harv's FED thread

Posted: Mon Feb 12, 2024 8:18 am

by Harv

Blacky wrote: ↑Sun Feb 11, 2024 10:32 pm

Still spins me out that a grey powered anything needs a parachute

The only class I can run this thing in is Modified. It has a 10.99 second cut-off. I only know of one grey motor that has ever run that fast, and he only did it once (Dennis Paul in a FED, 10.83s). I effectively need to build and campaign the world's quickest grey.

We can rebuild him. We have the technology. We can make him better, than he was. Better, stronger, faster.

Errol62 wrote: ↑Mon Feb 12, 2024 7:59 am

Those wheels look sick Harv

American Racing Torque-Thrust Ds, in 15x10. As close as I can get to a Halibrand without selling both kidneys. 10" may be a touch wide... I will have no problem with traction, but may well lift the nose of this thing. At some stage I want to put this thing on the dyno, but cannot run slicks on the rolling road. Will need to find some crappy 15", 16" or 17" wheels in Chev pattern to run radials on temporarily.

Cheers,

Harv

Re: Harv's FED thread

Posted: Tue Mar 05, 2024 6:40 am

by Harv

Re: Harv's FED thread

Posted: Tue Mar 05, 2024 9:28 am

by Blacky

I wooden trust that head if I were you Harv - it does knot look kosher

Re: Harv's FED thread

Posted: Tue Mar 05, 2024 9:33 am

by BS

Damn!!! This thing is cool!!!

Sent from my iPhone using Tapatalk

Re: Harv's FED thread

Posted: Tue Mar 05, 2024 11:03 am

by Harv

Blacky wrote: ↑Tue Mar 05, 2024 9:28 am

I wooden trust that head if I were you Harv - it does knot look kosher

I should have measured the head before I sent it our for a freshen up... had to get one of the Taswegian lumpy humpy boys to measure up one for me. Wait until I tek-screw the blower on the other side

BS wrote: ↑Tue Mar 05, 2024 9:33 am

Damn!!! This thing is cool!!!

There is a certain HAMBSTR that I need to line up a race with

Cheers,

Harv

Re: Harv's FED thread

Posted: Tue Mar 05, 2024 1:35 pm

by FireKraka

Re: Harv's FED thread

Posted: Tue Mar 19, 2024 1:09 pm

by Harv

Lining up some projects for the Easter break. One of them is the windshield for the FED. It only needs to be about 4" tall in the middle, and tapers down to nothing at either end. The mounting holes are already drilled in the cowl.

- windshield.jpg (267.38 KiB) Viewed 267 times

One option is to make it from thin ally sheet. I have a cardboard template, and it would be (relatively) easy to cut the aluminium, then bend it by hand to the curve of the cowl. Get it to sit right, put the bolts into either end of it, one in the middle, then the rest.

Another option is to make it from polycarbonate sheet. Poly sheet bends easily with a heat gun, and can be oven heated and draped over a buck. Not sure how I'd go about making a buck for this though - its a compound curve. The other option it to cut it roughly to shape, heat both sides of it with the heat gun (say 6" at a time), and try and hand form it (vertically) onto the cowl without burning the cowl paint (... sounds like a recipe for disaster) Thoughts appreciated.

Cheers,

Harv

Re: Harv's FED thread

Posted: Tue Mar 19, 2024 1:50 pm

by Blacky

If you are confident making it out of ally could you not then use the ally as a buck to make a polycarbonate one ?? a smoked polycarbonate screen would look cool - was thinking polished ally would too but may cause a glare issue with track lighting ......

Re: Harv's FED thread

Posted: Thu Apr 11, 2024 9:43 am

by Harv

Something so simple is driving me nuts.

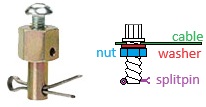

The fuel system on the FED needs a fuel shutoff valve. This is a simple ball valve with AN flared fittings, and a 1/4" thick handle that moves through 90º. The valve is operated via a bowden cable from the cockpit. To attach the cable to the valve handle I need a small gimbal, similar to the one shown in the image below left.

- gimbal from ARP bolt.jpg (8.43 KiB) Viewed 209 times

This is pretty simple tech... the same stuff that mounts the choke cable to a Stromberg carb. To make the fittings match the rest of the FED, I decided to make a gimbal out of a 10-24UNC ARP stainless bolt, similar to the image above right. All it needs is two holes, about 1mm diameter, drilled through the bolt.

Should be easy, right?

I started out with a 1mm cobalt bit, slow speed in the drill press (about 600rpm) and lots of cutting oil. After many minutes of drilling, I was getting nowhere. It ended up making a slight dent, drilled a little, then snapped off in the bolt. I said bad words, and worked on something else for a while.

I thought I would buy a gimble similar to the brass one shown above, but quite some Googling and I cannot find one locally. The cost for one ex-US is close to $35 parts plus $35 freight

Back to drilling the bolt. Got another fresh bolt, and bought some 1mm solid carbide drills. Tried low speed and high speed, dry and with cutting oil. No go. The bits snap before they bite.

Any suggestions on how to drill the bolt much appreciated.

Cheers,

Harv